Active coke/charcoal flue gas desulphurization denitration and elemental sulfur-recovery technology and device

A technology of desulfurization, denitrification, and activated coke, which is applied in the direction of sulfur preparation/purification, separation method, and separation of dispersed particles, which can solve secondary pollution and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

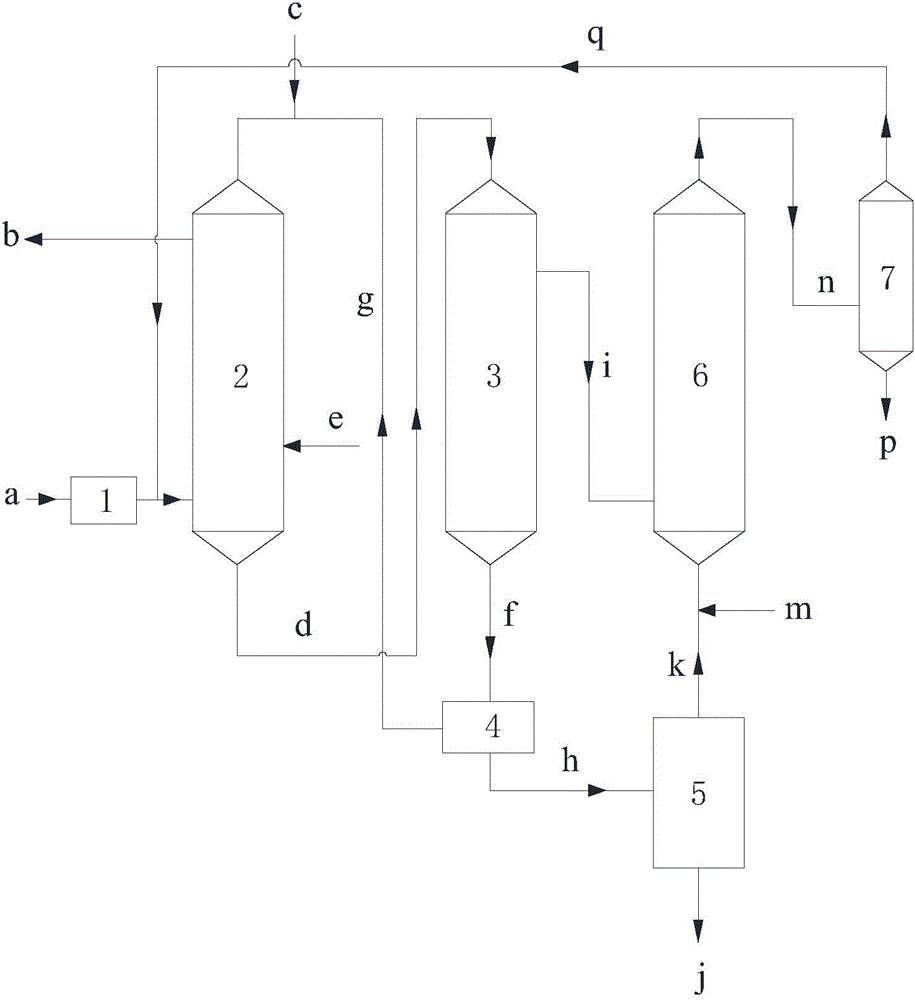

[0057] Such as figure 1 As shown, a device for realizing desulfurization and denitrification of activated coke / charcoal flue gas and recovery of elemental sulfur includes an adsorption tower 2, a screening machine 4, a regeneration tower 3, a gasifier 5 and a reduction tower 6. The bottom solid outlet of the adsorption tower 2 is connected with the top solid inlet of the regeneration tower 3 . The side wall flue gas inlet of the adsorption tower 2 is provided with a dust collector 1, preferably the dust collector 1 is an electric dust collector, and its outlet dust concentration is less than 100mg / Nm 3 . The side wall of the adsorption tower 2 is provided with an ammonia gas inlet and a clean flue gas outlet. The bottom solid outlet of the regeneration tower 3 is connected to the inlet of the screening machine 4 ; the gas outlet of the regeneration tower 3 is connected to the side wall gas inlet of the reduction tower 6 . The sieving machine 4 is provided with two outlets, ...

specific Embodiment 1

[0064] The above-mentioned device is used for desulfurization and denitrification of coal-fired boiler flue gas and steel sintering flue gas, and the specific process parameters are as follows:

[0065] The coal-fired boiler flue gas is discharged into the adsorption tower 2 for desulfurization and denitrification and elemental sulfur recovery processes. Control the temperature of the adsorption 2 tower to be 120°C, the temperature of the gasification furnace 5 to be 900°C, the temperature of the regeneration tower 3 to be 450°C, the temperature of the reduction tower 6 to be 500°C, and the condenser The temperature of 7 is -10°C.

specific Embodiment 2

[0066] The above-mentioned device is used for desulfurization and denitrification of coal-fired boiler flue gas and steel sintering flue gas, and the specific process parameters are as follows:

[0067] The coal-fired boiler flue gas is discharged into the adsorption tower 2 for desulfurization and denitrification and elemental sulfur recovery processes. Control the temperature of the adsorption tower 2 to be 160°C, the temperature of the gasification furnace 5 to be 800°C, the temperature of the regeneration tower 3 to be 300°C, the temperature of the reduction tower 6 to be 600°C, and the condenser The temperature of 7 is 0°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com