Application of metal sulfide mercury removal agent in washing removal of mercury in flue gas

A metal sulfide and mercury removal agent technology, applied in chemical instruments and methods, separation methods, dispersed particle separation, etc., can solve the problems of corrosion of mercury removal solution, secondary pollution of the environment, and lower mercury removal efficiency, and achieve anti-corrosion Excellent water properties, good mechanical properties, and high mercury removal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

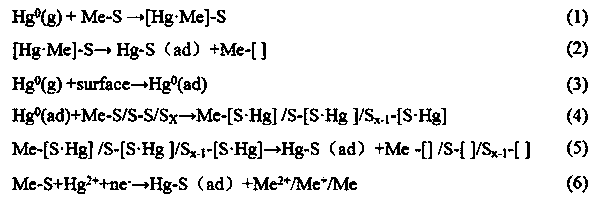

Method used

Image

Examples

Embodiment 1

[0034] Using equimolar amounts of ammonium sulfide and copper chloride as reactants, a metal sulfide mercury removal agent 1 was prepared by hydrothermal method in the presence of cetyltrimethylammonium bromide. The specific surface area of mercury removal agent 1 was 34.3m 2 / g. Add the metal sulfide mercury removal agent to the simulated flue gas scrubber, the set temperature of the cleaning liquid is 25°C, and the ratio of the added amount of the metal sulfide mercury removal agent to the cleaning liquid is 1kg / m 3 , the pH of the simulated washing solution is 2. Use the VM-3000 mercury detector to measure the mercury concentration in real time. The mass flow meter accurately controls the gas flow of each component to simulate the composition of the flue gas. The total gas flow is 1L / min, and the initial Hg 0 The concentration is 100±1μg / m 3 , in pure N 2 Under atmosphere, within 10h, the effect of metal sulfide mercury removal agent on Hg 0 The removal efficiency is ...

Embodiment 2

[0036] A metal sulfide mercury removal agent was prepared by a simple precipitation method in the presence of dodecyldimethylbenzylammonium bromide using ammonium sulfide, ferric chloride and copper chloride in a molar ratio of 2:1:1 as reactants 2. The specific surface area of mercury removal agent 2 is 20.3m 2 / g. Add the metal sulfide mercury removal agent to the simulated flue gas scrubber, the set temperature of the cleaning liquid is 25°C, and the ratio of the added amount of the metal sulfide mercury removal agent to the cleaning liquid is 1kg / m 3 , the pH of the simulated washing solution is 7. Use the VM-3000 mercury detector to measure the mercury concentration in real time. The mass flow meter accurately controls the gas flow of each component to simulate the composition of the flue gas. The total gas flow is 1L / min, and the initial Hg 0 The concentration is 100±1μg / m3, in pure N 2 Under atmosphere, within 10h, the effect of metal sulfide mercury removal agent ...

Embodiment 3

[0038] Using ammonium sulfide and copper chloride with a molar ratio of 1:1 as reactants, the metal sulfide mercury removal agent 3 was prepared by titration method, and the specific surface area of mercury removal agent 3 was 5.77m 2 / g. Add the metal sulfide mercury removal agent to the simulated flue gas scrubber, the set temperature of the washing liquid is 25°C, and the ratio of the metal sulfide mercury removal agent to the washing liquid is 5kg / m 3 , the pH of the simulated washing solution is 2. Use the VM-3000 mercury detector to measure the mercury concentration in real time. The mass flow meter accurately controls the gas flow of each component to simulate the composition of the flue gas. The total gas flow is 1L / min, and the initial Hg 0 The concentration is 100±1μg / m 3 , in pure N 2 Under atmosphere, within 10h, the effect of metal sulfide mercury removal agent on Hg 0 The removal efficiency was 85.2%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com