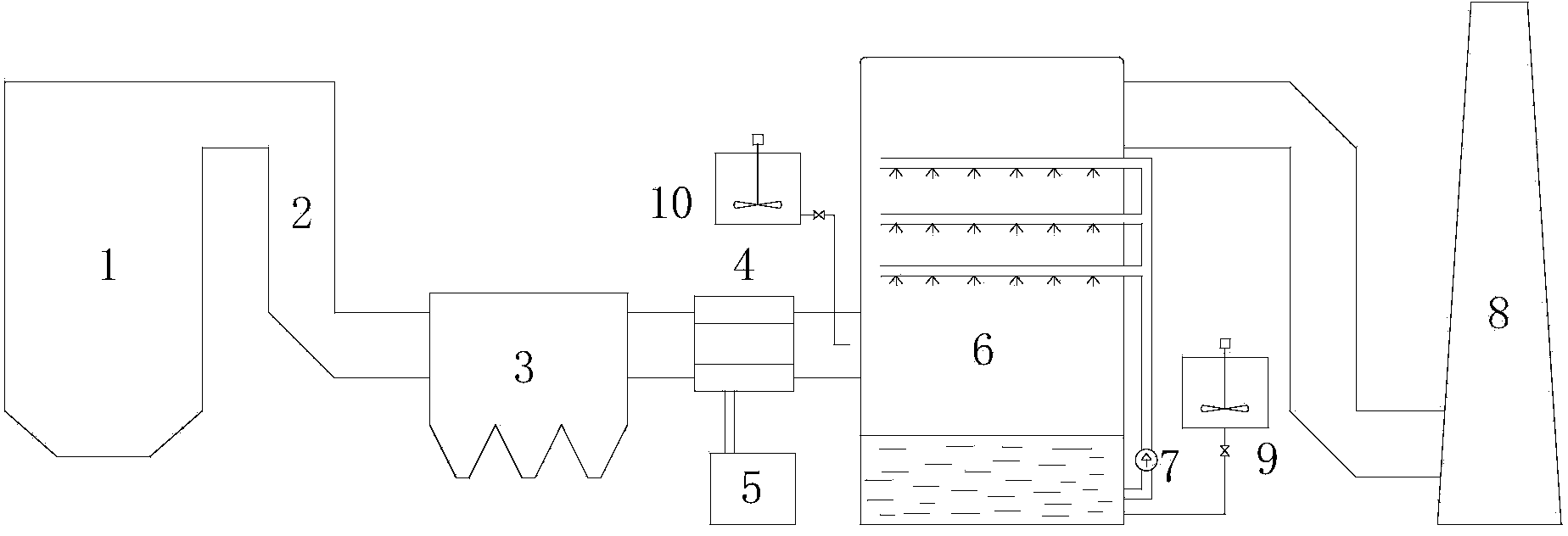

Flue gas treatment method for simultaneous desulfurization, denitrification and demercuration by calcium and magnesium method

A technology for desulfurization, denitrification, mercury removal, and flue gas treatment, which is applied in the field of flue gas treatment for simultaneous desulfurization, denitrification, and mercury removal by the calcium-magnesium method, can solve the problems of high cost, fast consumption of sulfite, etc. The effect of set rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] With device and process of the present invention, at 5m 3 The flue gas denitrification process is simulated on the experimental simulation device of / h scale. Flue gas volume 5m 3 / h, the flue gas composition is as follows: O 2 5%, NO 200ppm, SO 2 500ppm, the rest is nitrogen, Hg concentration is 20μg / Nm 3 , the flue gas temperature is 150 degrees Celsius, and the pressure is 1 atmosphere. Ozone according to the molar ratio O 3 : The ratio of NO=1.1 is injected, the oxidation rate of NO at the outlet can reach 90%, the concentration of the absorbed MgO slurry is 5%, the concentration of limestone slurry is 5%, and 0.1% iodine chloride slurry is added as a mercury removal agent. Spray absorption device, the number of spray layers is six, and the liquid-gas ratio is 5L / m 3 , the pH is controlled at 6.5, the desulfurization rate can reach 90%, the denitrification efficiency can reach 85%, and the mercury removal efficiency can reach more than 80%.

Embodiment 2

[0052] With device and process of the present invention, at 5m 3 The flue gas denitrification process is simulated on the experimental simulation device of / h scale. Flue gas volume 5m 3 / h, the flue gas composition is as follows: O 2 12%, NO 230ppm, SO 2 550ppm, Hg concentration 20μg / Nm 3 , and the rest is nitrogen, the flue gas temperature is 110 degrees Celsius, and the pressure is 1 atmosphere. Ozone according to the molar ratio O 3 : The ratio of NO=1.2 is injected, the oxidation rate of NO at the outlet can reach 95%, the absorbed MgO slurry concentration is 10%, the limestone slurry concentration is 5%, and 1% ammonium iodide slurry is added as a mercury removal agent. The pH is controlled at 6.5, combined with the bubbling absorption device, the desulfurization rate can reach 90%, the denitrification efficiency can reach more than 85%, and the mercury removal efficiency can reach more than 90%.

Embodiment 3

[0054] With the device and process of the present invention, the flue gas flow rate is 4000Nm 3 / h,O 2 9%, NO 250ppm, SO 2 500ppm, Hg concentration 20μg / Nm 3 , and the rest is nitrogen, the flue gas temperature is 90 degrees Celsius, and the pressure is 1 atmosphere. Ozone according to the molar ratio O 3 : The ratio of NO=1.2 is injected, the oxidation rate of NO at the outlet can reach 95%, the absorbed MgO slurry concentration is 8%, the limestone slurry concentration is 10%, and 0.5% ammonium hypochlorite slurry is added as a mercury removal agent , combined with the spray absorption device, the number of spray layers is six, and the liquid-gas ratio is 8L / m 3 , the pH is controlled at 6.5, the desulfurization rate can reach 95%, the denitrification efficiency can reach 90%, and the mercury removal efficiency can reach more than 85%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com