Novel activated carbon fiber adsorbing substance as well as preparation method and use thereof

A technology of activated carbon fiber and adsorbent, which is applied in the application field of mercury removal adsorbent, can solve the problems of mercury removal, limited research stage, etc., and achieves the effects of strong adsorption capacity, high reactivity and easy realization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

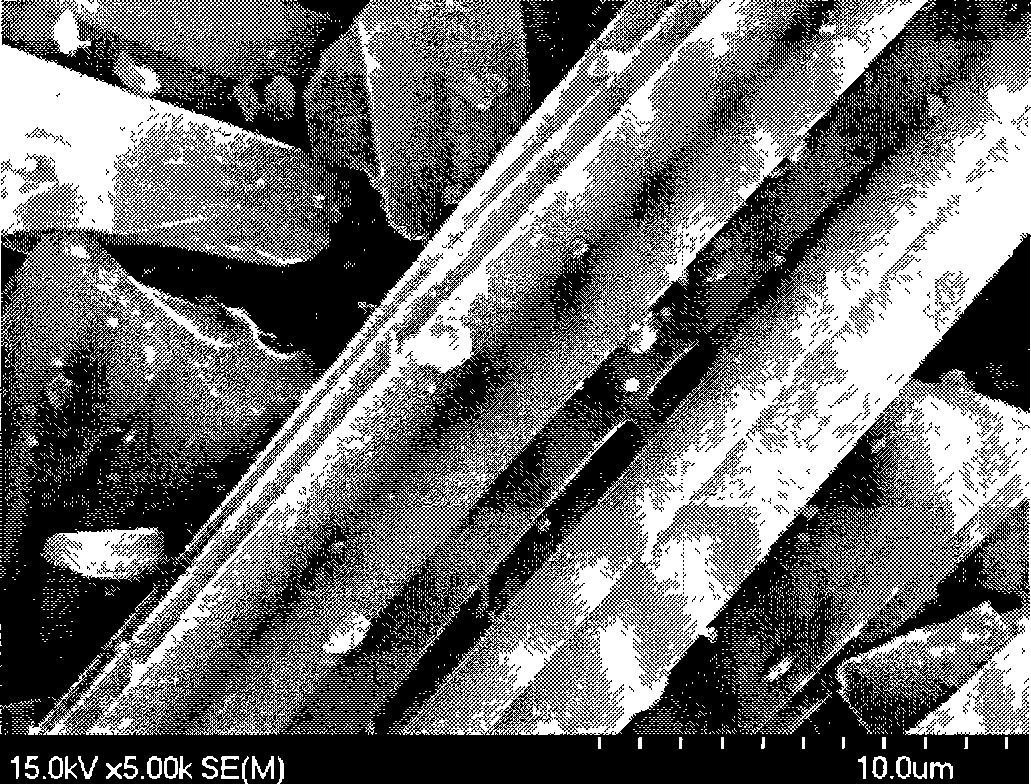

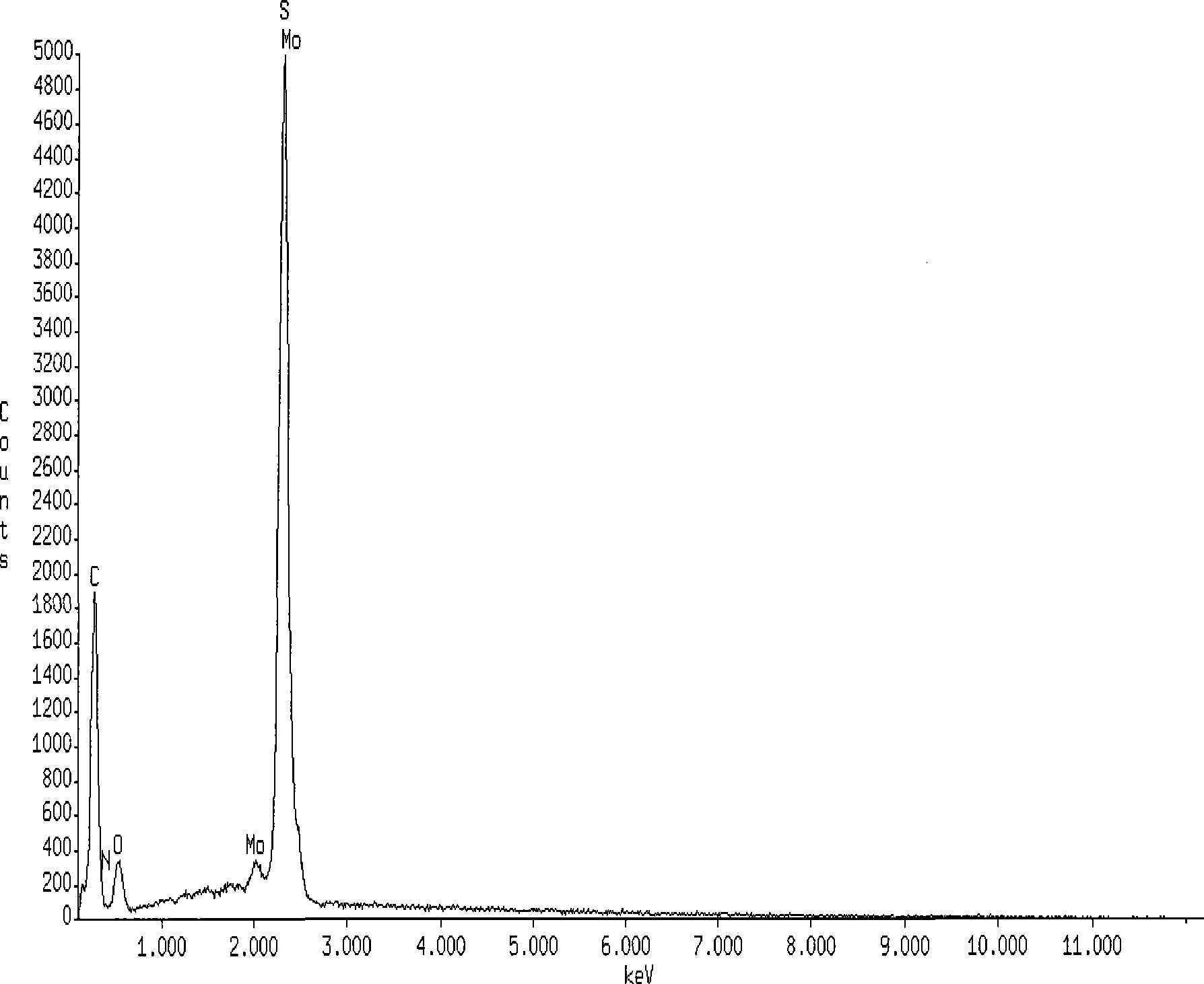

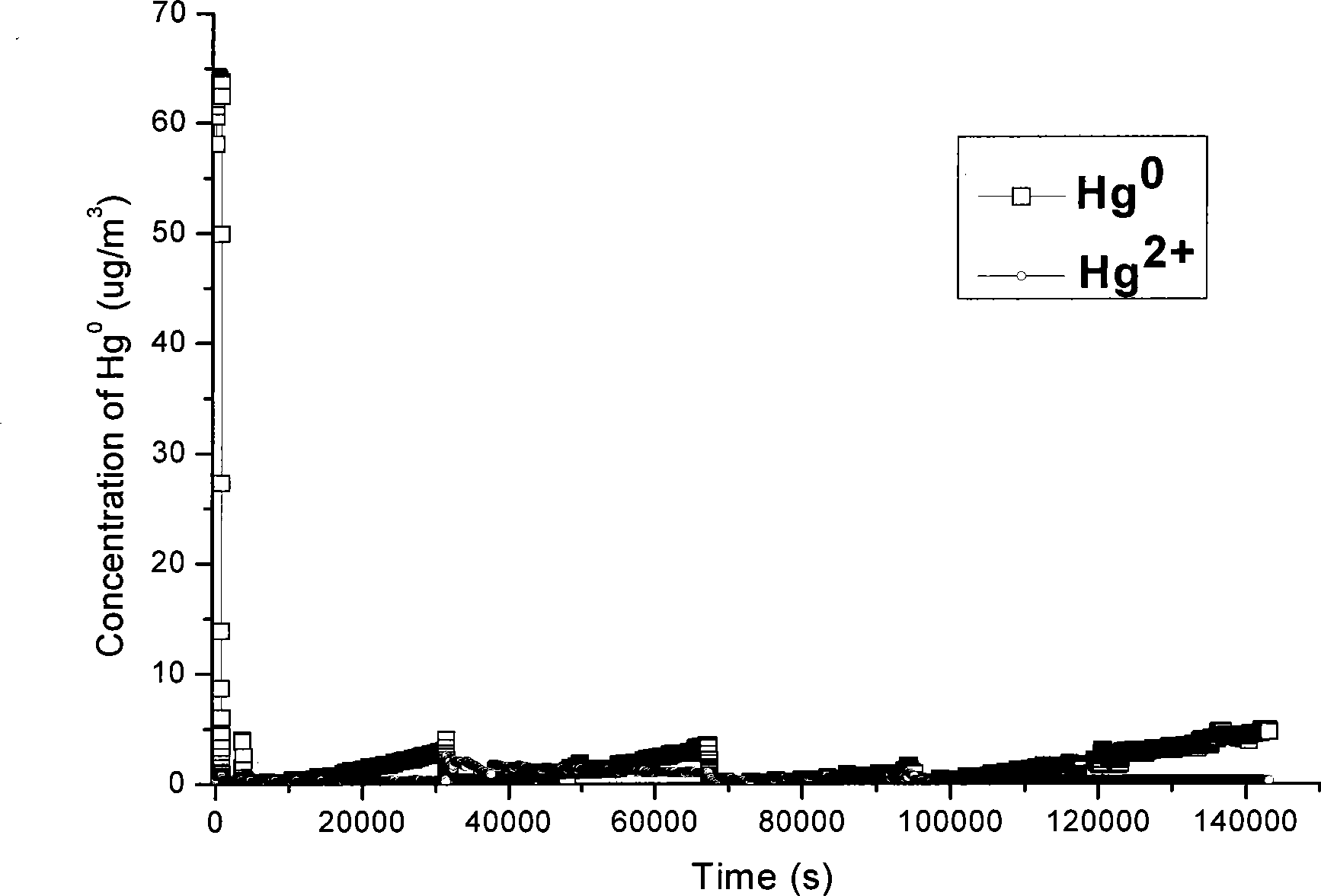

Embodiment 1

[0034] Weigh 1 g of ammonium heptamolybdate and place it in a beaker, add deionized water and stir to dissolve it. Transfer the ammonium heptamolybdate solution into a 250ml volumetric flask, and set to volume to obtain an ammonium heptamolybdate solution with a concentration of 4mg / ml. Get 4g activated carbon fiber (specific surface area is 1000m 2 / g of viscose-based activated carbon fiber) is placed in a 250ml brown jar, and 250ml of ammonium heptamolybdate solution is added. Under the condition of water bath at 40°C, after adsorption and impregnation for 24 hours, the activated carbon fibers were rinsed repeatedly with deionized water. Then it was placed in a porcelain boat, and heated and decomposed for 3 hours in a tube furnace at 450°C under an Ar atmosphere (air flow rate of 200ml / min), to obtain the surface-loaded molybdenum trioxide (MoO 3 ) of activated carbon fibers. During the thermal decomposition process, dilute hydrochloric acid solution is required to absor...

Embodiment 2

[0037] Weigh 1 g of ammonium heptamolybdate and place it in a beaker, add deionized water and stir to dissolve it. Transfer the ammonium heptamolybdate solution into a 250ml volumetric flask, and set to volume to obtain an ammonium heptamolybdate solution with a concentration of 4mg / ml. Get 4g activated carbon fiber (specific surface area is 1000m 2 / g of viscose-based activated carbon fiber) is placed in a 250ml brown jar, and 250ml of ammonium heptamolybdate solution is added. Under the condition of a water bath at 45°C, after standing for about 24 hours for adsorption, the activated carbon fiber was washed repeatedly with deionized water. Then it was placed in a porcelain boat, and heated and decomposed for 3.5 hours in a tube furnace at 450 ° C under an Ar atmosphere (air flow rate of 200 ml / min), and the surface-loaded molybdenum trioxide (MoO 3 ) of activated carbon fibers. During the thermal decomposition process, dilute hydrochloric acid solution is required to abso...

Embodiment 3

[0040] Weigh 10 g of ammonium heptamolybdate and place it in a beaker, add deionized water and stir to dissolve it, and prepare an ammonium heptamolybdate solution with a concentration of 4 mg / ml. Get 8g activated carbon fiber (specific surface area is 1000m 2 / g of viscose-based activated carbon fiber) is placed in a 500ml brown jar, and 500ml of ammonium heptamolybdate solution is added. Under the condition of a water bath at 50°C, after standing for adsorption for 48 hours, the activated carbon fiber was washed repeatedly with deionized water. Then it was placed in a porcelain boat, and heated and decomposed for 4 hours in a tube furnace at 500°C under an Ar atmosphere (air flow rate of 200ml / min), to obtain a surface-loaded molybdenum trioxide (MoO 3 ) of activated carbon fibers. During the thermal decomposition process, dilute hydrochloric acid solution is required to absorb the tail gas (NH 3 exhaust gas).

[0041] Take 5g MoO 3 - Activated carbon fiber is placed in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com