Method and device for removing mercury from high-temperature flue gas of fire coal

A technology of a high-temperature flue gas and gas guide device is applied in the field of dust removal and mercury removal, which can solve the problems of not being popularized and used, and achieve the effects of high use efficiency, uniform gas introduction and exhaust gas guide, and high mercury removal efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

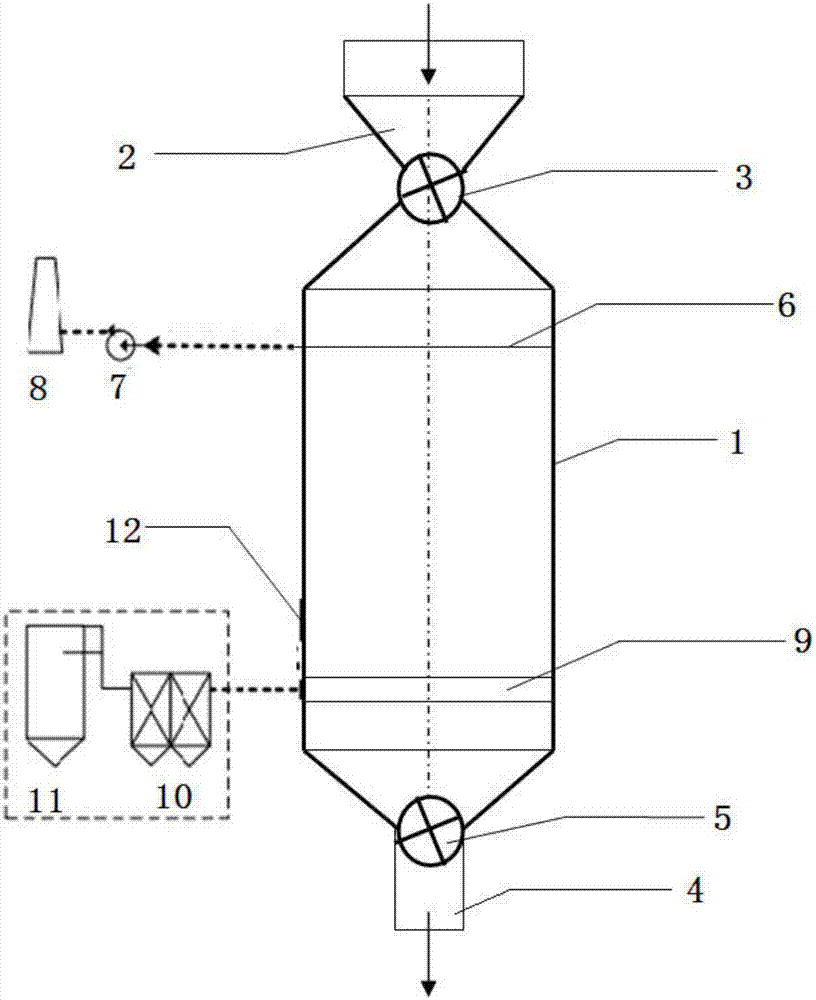

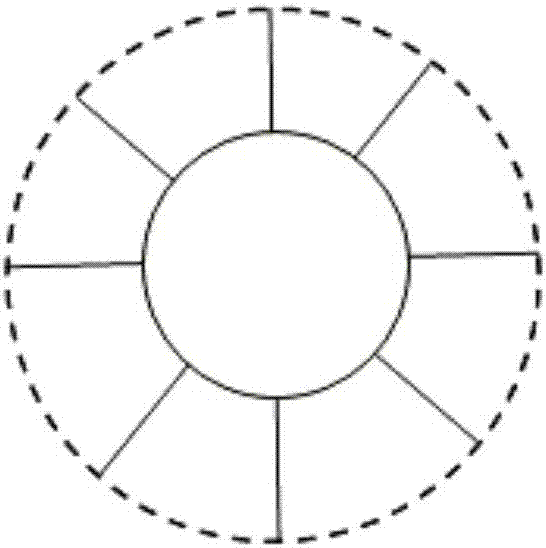

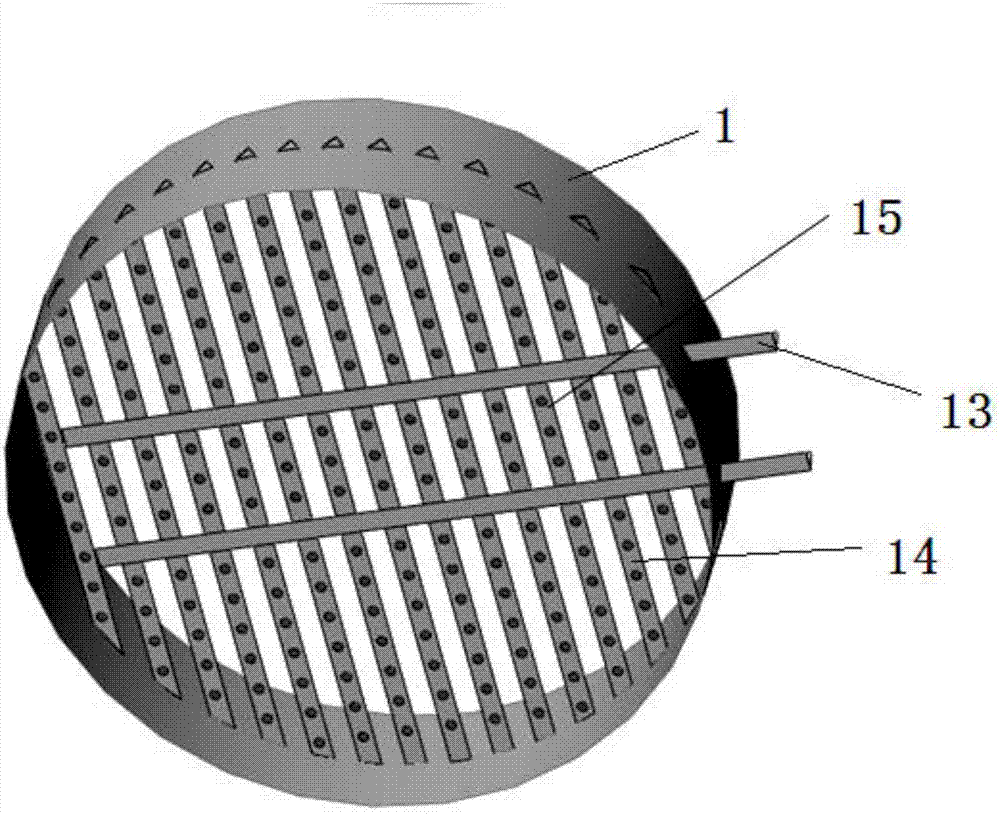

[0028] Embodiment of the present invention: a method for removing mercury from coal-fired high-temperature flue gas, which adopts the method of uniformly feeding the flue gas mercury removal adsorbent into the mercury removal reactor through the control of the electric rotary valve, and the high-temperature flue gas passes through the intake air The gas guiding device enters the mercury removal reactor, the high-temperature flue gas and the flue gas mercury removal agent form convection in the mercury removal reactor, and a vibrator is installed outside the mercury removal reactor. The amalgam drops evenly in layers, and can also shake off the mercury removal adsorbent on the inlet air guide device and the circular air outlet device, and realize the full reaction between the high temperature flue gas and the flue gas mercury removal agent, and the flue gas after mercury removal passes through the circular The ring outlet device leads out to realize the purpose of demercurizing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com