Environment-friendly active carbon catalyst as well as preparation method and application thereof to flue gas mercury removal

The technology of activated carbon and catalyst is applied in the application field of environment-friendly activated carbon catalyst and its preparation, and mercury removal from flue gas, and achieves the effects of facilitating pressure drop, reducing use cost and facilitating operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

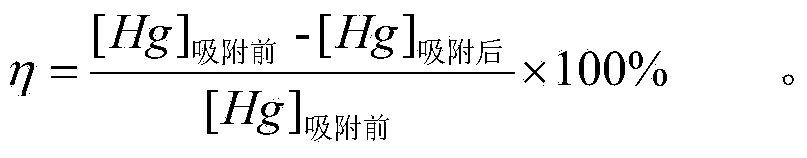

Method used

Image

Examples

Embodiment 1

[0040] In this example, the corn stalk was crushed and sieved to obtain corn stalk particles with a particle size of less than 20 meshes. 2 In the atmosphere, the crucible containing corn stalk particles was placed in a high temperature furnace at a furnace temperature of 600° C. for 10 minutes to obtain black corn stalk coke, which was taken out and placed in a desiccator to cool. The cooled corn stalk is milled and sieved to obtain a powder with a particle size of less than 60 meshes, which is the precursor of corn stalk coke.

[0041] In terms of weight %, mix the following components: 66% cornstalk coke, 14% sulfur powder, 17% (in SiO 2 (By weight) silica sol, 3% sesbania powder, the mixture is mixed with a 3wt% dilute nitric acid aqueous solution dropwise, then extruded into 2mm strips, and dried at 110°C for 12 hours.

[0042] With Fe element weight accounting for 5% of the total weight of the catalyst, an aqueous ferric nitrate solution was prepared as an immersion solution, ...

Embodiment 2

[0045] In this example, the corn stalk was crushed and sieved to obtain corn stalk particles with a particle size of less than 20 meshes. 2 In the atmosphere, the crucible containing corn stalk particles was placed in a high temperature furnace at a furnace temperature of 600° C. for 10 minutes to obtain black corn stalk coke, which was taken out and placed in a desiccator to cool. The cooled corn stalk is milled and sieved to obtain a powder with a particle size of less than 60 meshes, which is the precursor of corn stalk coke.

[0046] In terms of weight %, mix the following components: 60% cornstalk coke, 12% selenium dioxide, 25% cordierite powder, 3% sesbania powder, where the mixture is added dropwise with a 3wt% dilute nitric acid solution and kneaded evenly , Then extruded into 2mm strips, dried at 110°C for 12 hours.

[0047] The manganese nitrate solution was prepared as an impregnating liquid based on the weight of Mn element accounting for 5% of the total weight of the ...

Embodiment 3

[0050] In this example, the rice stalk was crushed and sieved to obtain rice stalk particles with a particle size of less than 20 meshes. 2 In an atmosphere, the crucible containing rice stalk particles was placed in a high-temperature furnace at 700°C for 10 minutes to obtain black rice stalk coke, which was taken out and placed in a desiccator to cool. The cooled rice stalk coke is milled and sieved to obtain a powder with a particle size of less than 60 meshes, which is the precursor of the rice stalk coke.

[0051] In terms of weight %, mix the following components: 70% rice stalk coke, 9% sulfur powder, 18% cordierite powder, 3% sesame powder, where the mixture is mixed with a 3wt% dilute nitric acid aqueous solution dropwise and kneaded evenly. It was then extruded into 2mm strips and dried at 110°C for 12 hours.

[0052] The ferric nitrate solution was prepared as the immersion liquid based on the weight of Fe element accounting for 5% of the total weight of the catalyst, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com