Metal organic frame composite material and preparation method thereof

A metal-organic framework and composite material technology, applied in the field of metal-organic framework composite materials and their preparation, can solve problems such as reducing specific surface area, and achieve the effects of uniform distribution and stable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] The preparation of embodiment 1, ZIF-8 / polymer nanowire

[0033] (1) 400ml, 2mg / ml polymer PEG 113 - b -P4VP 67 After the nanowires were assembled in water, 0.4 ml of 1,4-dibromobutane was added for cross-linking (the degree of cross-linking was 100%), and stirred at room temperature for 2 days. After centrifugation, the solvent was switched to methanol, and the concentration of polymer nanowires was 2 mg / ml.

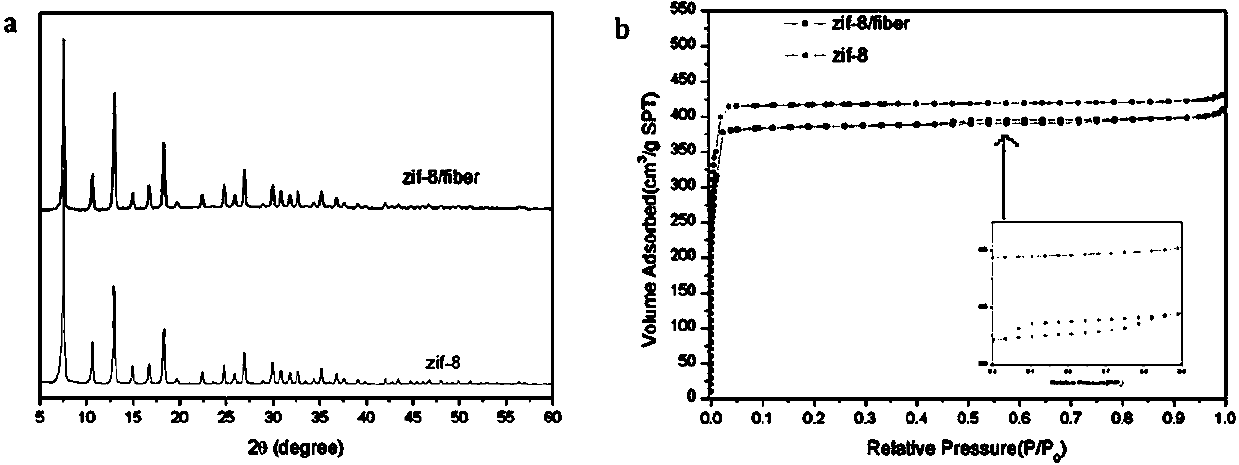

[0034] (2) Add 10ml polymer nanowire solution, 15ml methanol, and 25ml Zn(NO 3 )2 ·6H 2 O (250mM) methanol solution, 50ml 2-methylimidazole (250mM) methanol solution. Shake well and let stand at room temperature. After 24 hours, a white precipitate was obtained, which was collected by centrifugation, washed twice with methanol, and dried overnight in a vacuum oven to obtain 0.1025 g of a white solid. The field emission scanning electron microscopy results of the product are as follows figure 1 , XRD and nitrogen adsorption-desorption experiments such as ...

Embodiment 2

[0035] The preparation of embodiment 2, ZIF-8 / polymer nanowire

[0036] Polymer nanowire preparation process such as example 1 (1)

[0037] Add 10ml polymer nanowire solution, 15ml methanol, and then add 25ml Zn(NO 3 ) 2 · 6H 2 O (250mM) methanol solution, 25ml 2-methylimidazole (250mM) methanol solution. Shake well and let stand at room temperature. After 24 hours, a white precipitate was obtained, which was collected by centrifugation, washed twice with methanol, and dried overnight in a vacuum oven to obtain 0.1248 g of a white solid. The field emission scanning electron microscopy results of the product are as follows image 3 , the compressive strength as Figure 5 ZIF-8 / nanofiber.

Embodiment 3

[0038] Example 3, using polymer nanowires as a template, ZIF-8 grows into a ZIF-8 nanowire network along the polymer nanowires

[0039] Polymer nanowire preparation process such as example 1 (1)

[0040] Add 2ml of polymer nanowire (2mg / ml) solution, 83ml of methanol, and then add 5ml of Zn(NO 3 ) 2 ·6H 2 O (250mM) methanol solution, 10ml 2-methylimidazole (250mM) methanol solution. Shake well and let stand at room temperature. After 24 hours, a white flocculent precipitate was obtained, which was collected by centrifugation, washed twice with methanol, and dried overnight in a vacuum oven to obtain 0.0635 g of a white solid. The field emission scanning electron microscopy results of the product are as follows Figure 4 , the compressive strength as Figure 5 ZIF-8 fiber network.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com