Porous flow field fuel cell monomer without bipolar plate and series-parallel electric pile structure

A fuel cell and bipolar plate technology, applied in fuel cells, fuel cell parts, circuits, etc., can solve problems such as poor cooling consistency, reduced battery performance, increased flow resistance, and droplet discharge, achieving increased Effects of electrode effective reaction area, reduction and number of end plates, reduction in weight and volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

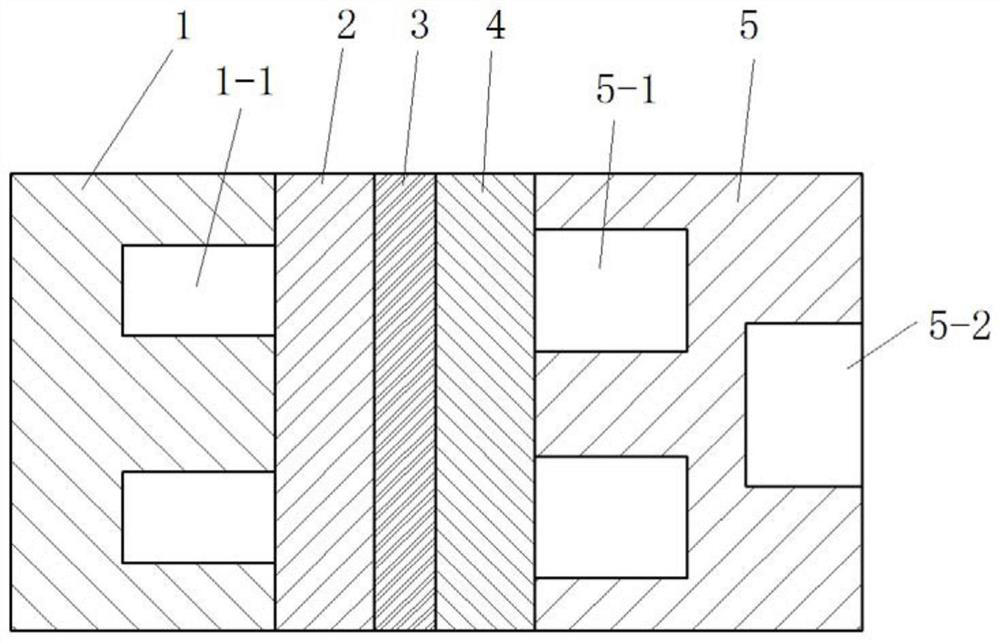

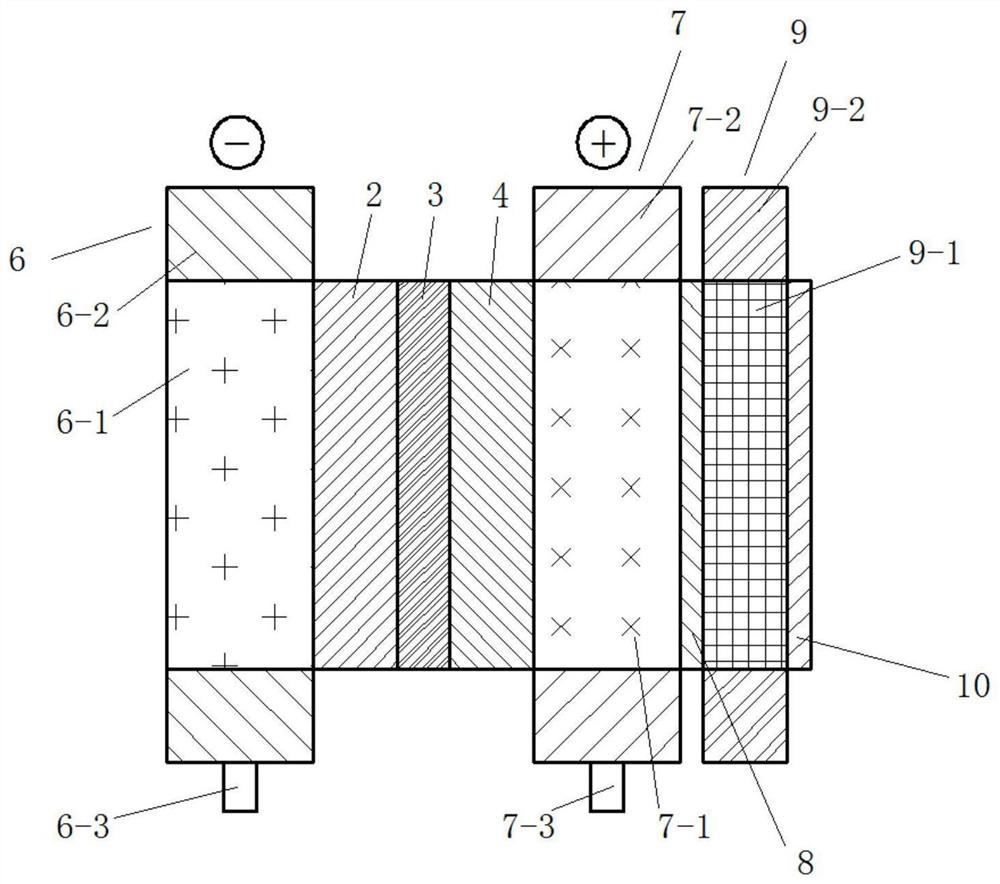

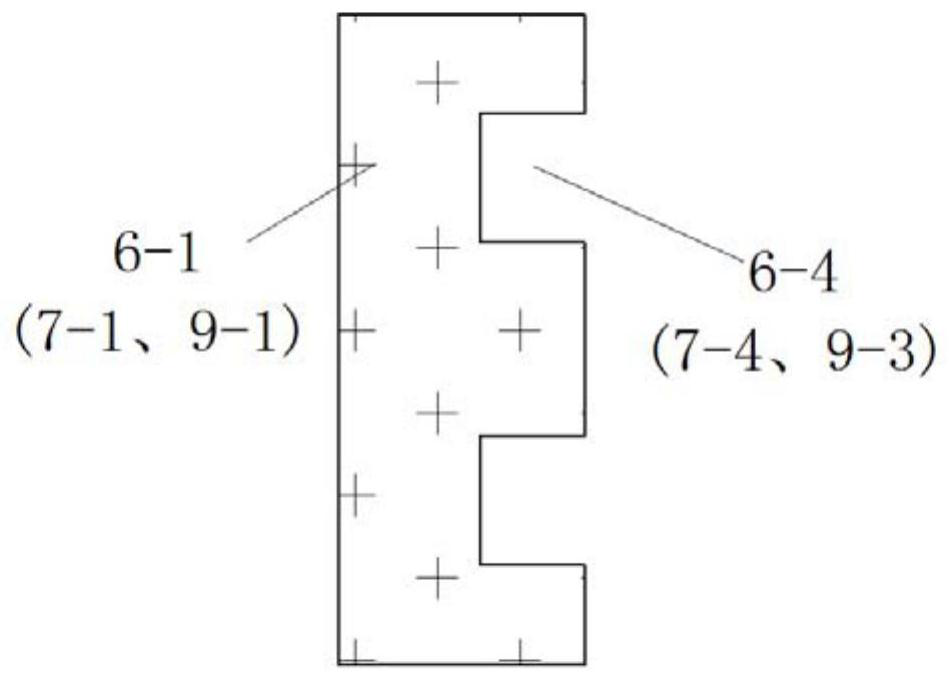

[0041] see Figure 1 to Figure 7 , figure 1 It is a schematic diagram of a traditional graphite plate fuel cell; figure 2 It is a schematic diagram of a single porous flow field fuel cell without a bipolar plate in the present invention; image 3 It is a schematic cross-sectional view of the porous material of the present invention along the flow channel in the thickness direction; Figure 4 It is a schematic diagram of the non-uniform porosity layout of the porous material of the present invention; Figure 5 It is a schematic diagram of parallel connection of shared anodes of two fuel cell monomers in the present invention; Figure 6 It is a schematic diagram of the parallel connection of two fuel cell monomers sharing the cooling layer in the present invention; Figure 7 It is a schematic diagram of the structure of the series-parallel stack of the present invention.

[0042] Such as figure 1 As shown, the traditional graphite plate fuel cell consists of an anode flow...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com