Catalyst powder, catalyst electrode and electrochemical device

A catalyst and electrochemical technology, which is applied in the field of electrochemical devices, can solve problems such as increased binder content, small specific surface area of catalyst particles, and reduced stability of catalyst layers, and achieve the effect of improving output characteristics and increasing effective reaction area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

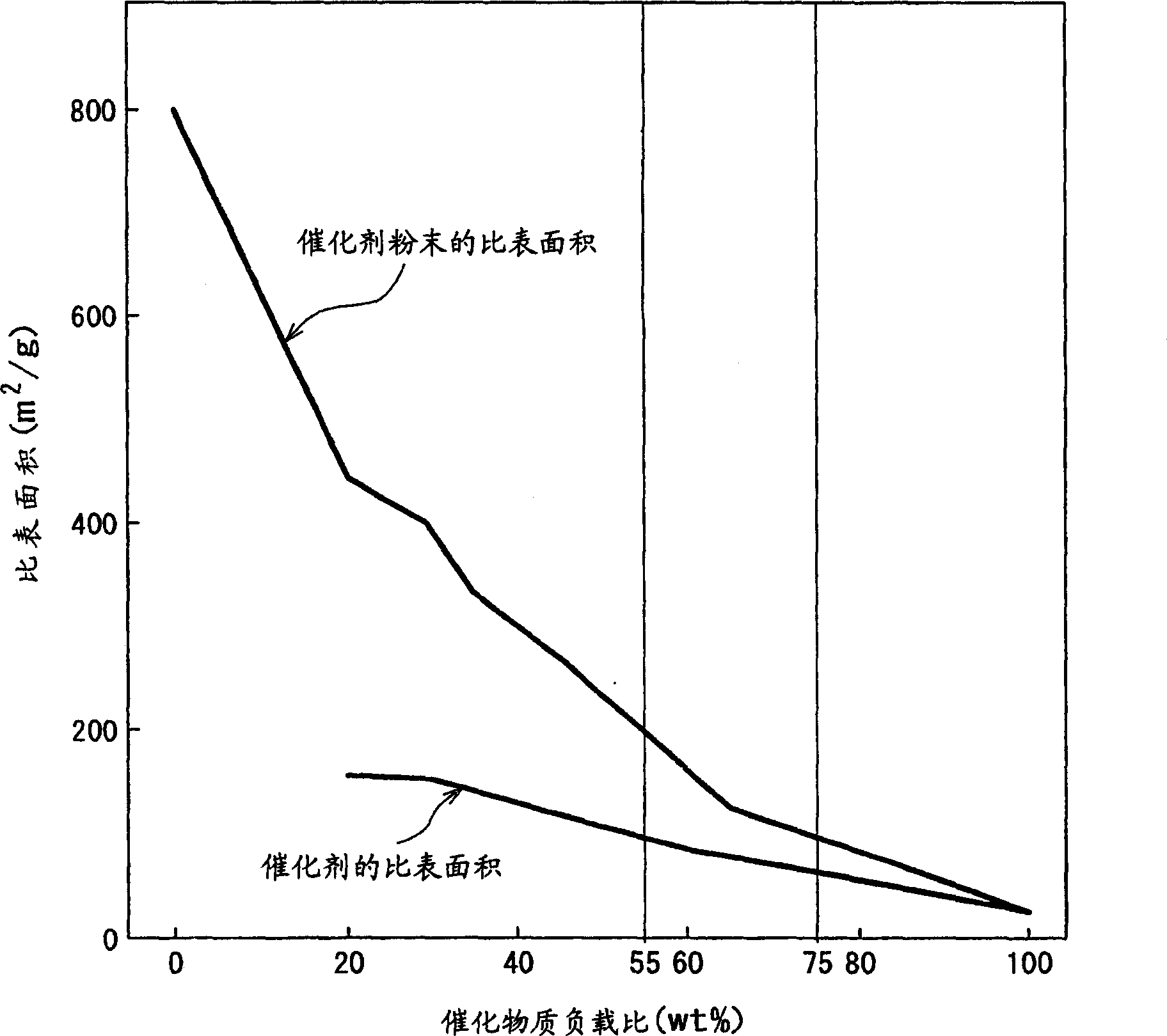

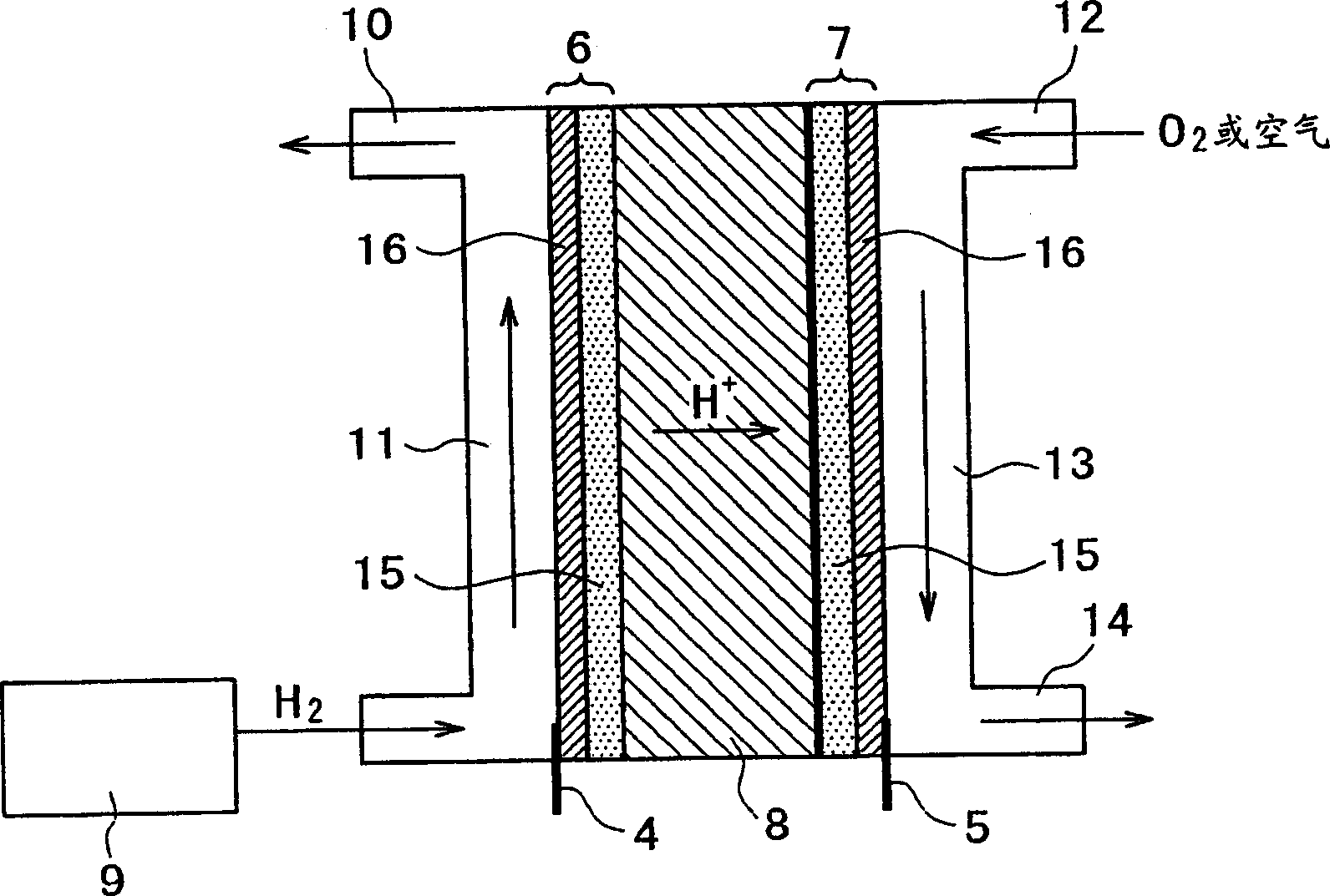

[0066] In 10 parts by weight of Ketjenblack EC (a product of Ketjenblack International Corporation; specific surface area: 800m 2 / g; the same applies below) on the surface of platinum catalyst powder (specific surface area: 130m 2 / g), add 10 parts by weight of pure water, and after fully wetting, add 30 parts by weight of 1-propanol and 60 parts by weight of 5% Nafion (registered trademark; a product of Dupont) solution in the mixture, The resulting mixture is then mixed well. The coating material thus obtained was applied to a water-repellent-treated gas-permeable current collector, and dried to obtain a platinum areal density of 2 mg / cm 2 The oxygen electrode (cathode).

[0067] In addition, in 10 parts by weight of catalyst powder containing platinum ruthenium alloy supported on the surface of Ketjenblack EC in a weight ratio of 60 wt % (specific surface area: 230 m 2 / g), 20 parts by weight of pure water was added, and after sufficient wetting, 20 parts by weight of 1...

Embodiment 2

[0070] An MEA and an electrochemical device were prepared in the same manner as in Example 1, except that 10 parts by weight of pure water was added to 10 parts by weight of the Ketjenblack EC containing 55% by weight of Platinum catalyst powder (specific surface area: 200m 2 / g), and after sufficient wetting, 20 parts by weight of 1-propanol and 90 parts by weight of 5% Nafion solution were added to the mixture, followed by thorough mixing of the resulting mixture. The coating material thus obtained was applied to a water-repellent-treated gas-permeable current collector, and dried to obtain a platinum areal density of 2 mg / cm 2 The oxygen electrode (cathode).

Embodiment 3

[0072] An MEA and an electrochemical device were prepared in the same manner as in Example 1, except that 10 parts by weight of pure water was added to 10 parts by weight of the Ketjenblack EC containing 75% by weight of Platinum catalyst powder (specific surface area: 100m 2 / g), and after fully wetting, 10 parts by weight of 1-propanol and 40 parts by weight of 5% Nafion solution were added to the mixture, and then the resulting mixture was thoroughly mixed. The coating material thus obtained was applied to a water-repellent-treated gas-permeable current collector, and dried to obtain a platinum areal density of 2 mg / cm 2 The oxygen electrode (cathode).

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com