Carbon/titanium niobium oxide composite negative electrode material and preparation and application thereof

A technology of titanium-niobium oxide and composite materials, which is applied in the field of lithium-ion batteries and can solve the problems of poor conductivity of titanium-niobium oxide negative electrode materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

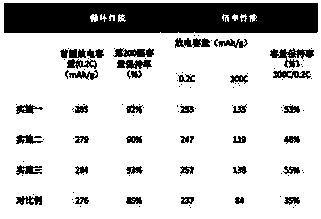

Examples

Embodiment 1

[0024] In this embodiment, the carbon / titanium niobium oxide negative electrode composite material for lithium ion supercapacitor is carried out according to the following steps:

[0025] (1) According to titanium niobium oxide TiNb 2 o 7 The stoichiometric ratio, respectively weighed 8.5mL butyl titanate and 13.3g niobium pentoxide dispersed in 100mL absolute ethanol;

[0026] (2) Weigh 0.2g of CNT and place it in a beaker containing 200mL of ethanol. After ultrasonication at 600W for 1h, the ethanol dispersion of butyl titanate and niobium pentoxide in step (1) is slowly Added to the ethanol solution of CNT;

[0027] (3) Add the above mixed solution into a centrifuge tube and perform ultracentrifugation at a speed of 61000 r / min for 8 minutes. After centrifugation, the product was heated at 70 °C for 20 h to obtain the precursor of the titanium-niobium oxide composite material; it was heated in 3% H 2 In a reducing atmosphere of Ar / Ar, react at a temperature of 700° C. f...

Embodiment 2

[0033] The carbon / titanium niobium oxide composite material and battery were prepared by the same method as in Example 1, except that the content of CNT was 10% by mass.

Embodiment 3

[0034] Example 3: The carbon / titanium niobium oxide composite material and battery were prepared by the same method as in Example 1, except that the carbon material was graphene, and its mass percentage was 5%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com