Calcium vanadate composite material as well as preparation method and application thereof

A composite material, calcium vanadate technology, applied in the field of electrochemistry, can solve the problems of poor electrochemical performance and poor electrical conductivity such as high rate performance and cycle stability of aqueous zinc-ion batteries, and achieve excellent electrochemical performance and electrical conductivity , good capacity and high cycle stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

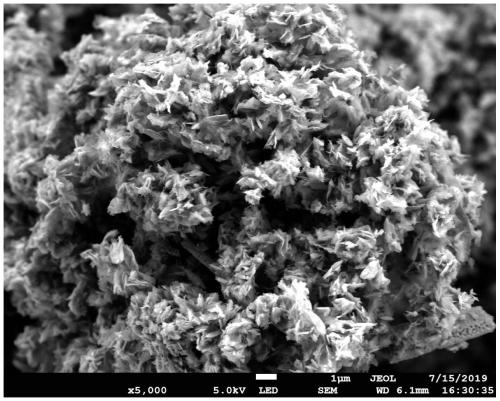

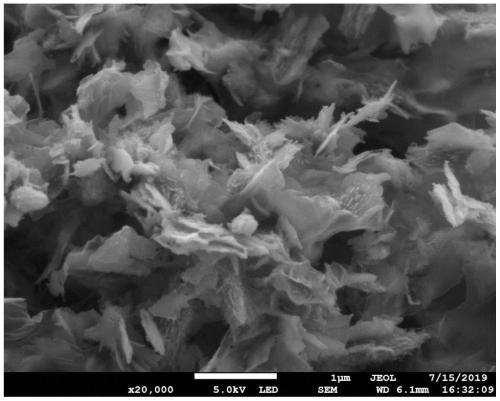

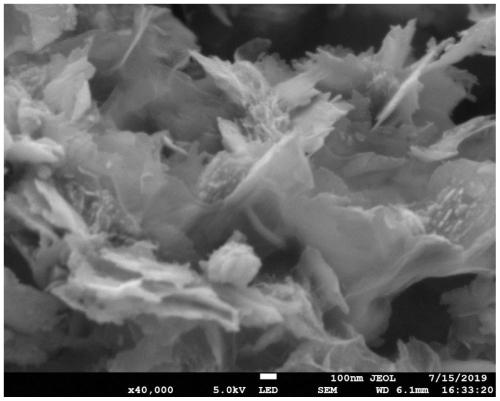

[0032] The calcium vanadate composite material of the present embodiment is made of CaV 4 o 9 The sheet material formed by compounding with graphene oxide (GO) has a mass ratio of 38.8:1.

[0033] Two, the embodiment of the preparation method of calcium vanadate composite material

Embodiment 2

[0035] The present embodiment is the preparation method of the calcium vanadate composite material in embodiment 1, comprises the following steps:

[0036] (1) Add 0.0741g of Ca(OH) 2 , 0.01g of GO was mixed with 10mL of deionized water and 10mL of glycerin, then ultrasonicated for 1h, and then stirred for 1h to obtain mixed solution A;

[0037] (2) Put 0.3679g of V 2 o 5 Added to 10 mL of deionized water and 5 mL of H 2 o 2 In the formed mixed solution (i.e. hydrogen peroxide), stir at a constant temperature at 20° C. for 2 hours to obtain mixed solution B;

[0038] (3) Mix the mixed solution A with the mixed solution B, stir it for 2 hours, place it in a hydrothermal kettle, and keep it warm at 200°C for 48 hours; then cool it naturally, then filter it, and wash the obtained solid with deionized water and ethanol successively, Dried to obtain the precursor;

[0039] (4) Precursor is first kept at 400° C. for 8 hours in an argon atmosphere, then heated to 500° C. and ke...

Embodiment 3

[0042] In this example, the calcium vanadate composite material in Example 1 is used as the positive electrode active material to assemble an aqueous zinc-ion battery, and the specific assembly method is as follows:

[0043] The calcium vanadate composite material in Example 1 is mixed with Super P (conductive carbon black), PTFE (polytetrafluoroethylene) according to the mass ratio of 6:3:1, then add 5mL alcohol and stir for 2h, and the cold wind blows the slurry to After it becomes viscous, use a spoon to press the material evenly until it is semi-cured, take it out and put it on a smooth glass plate, lubricate it with alcohol, spread weighing paper on it, and roll the film with a glass rod; after drying the prepared film, press it onto a stainless steel plate It is further dried on the net, and then cut into pieces to obtain positive electrode sheets.

[0044]Put the positive electrode sheet, glass fiber (diaphragm) and zinc sheet (negative electrode) into the shell in orde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com