Method for preparing aluminum/hydrogen peroxide monomer batteries

A single battery and hydrogen peroxide technology, applied in battery electrodes, regenerative fuel cells, circuits, etc., can solve the problems of low effective reaction area of electrodes, low utilization rate of active materials, and lower specific energy of batteries, so as to improve effective reaction Effects of area, weight reduction, and specific energy improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

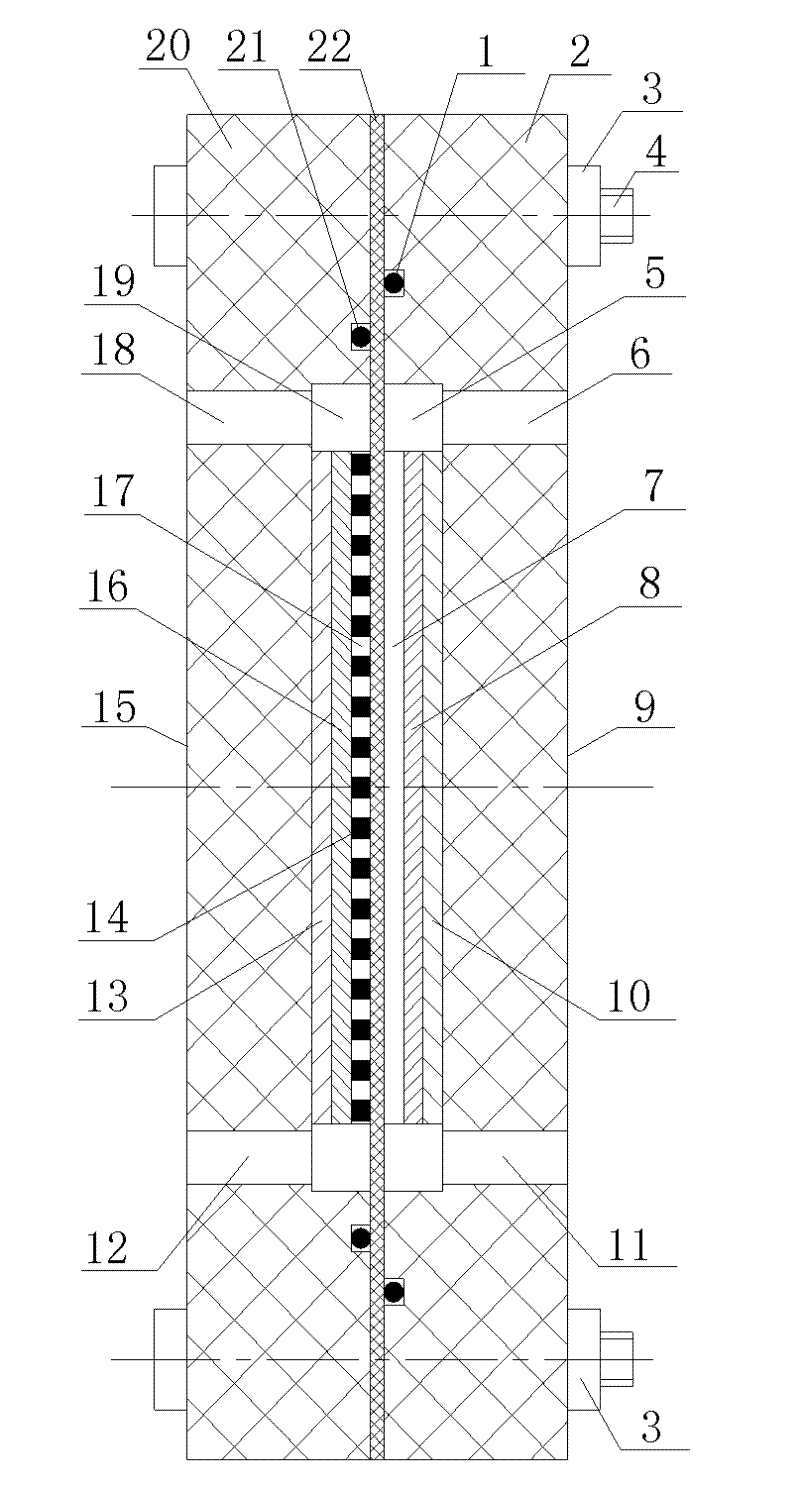

[0037] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

[0038] Manufacturing process of the present invention:

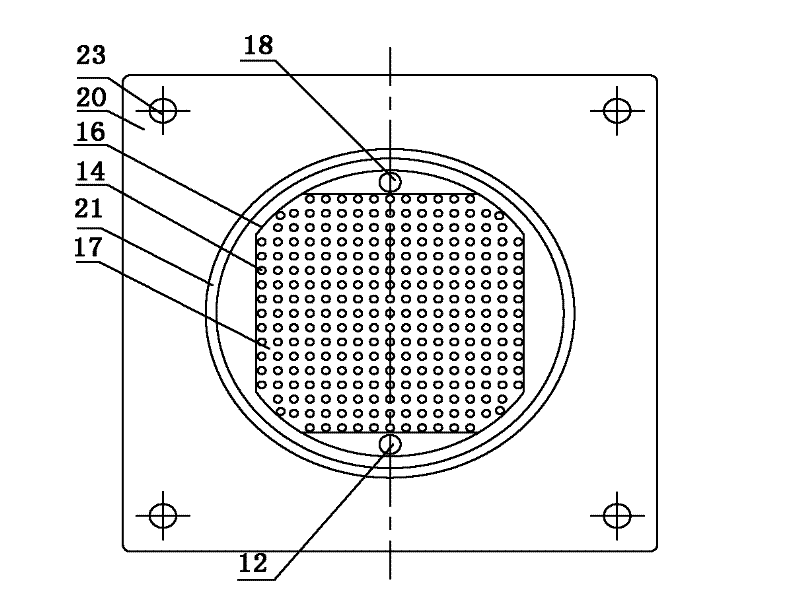

[0039] Preparation of the anode part:

[0040] like image 3 As shown, first select an aluminum plate with a thickness of 0.5mm, square sides, and rounded corners, and connect the ends of the four rounded corners to form a round aluminum plate as the anode 16. The phenolic resin of 0.5mm, diameter 2mm is used as granular spacer 14, and the gap between granular spacers forms anode flow channel 17, selects the nickel plate with thickness 1mm, shape and size identical with anode as anode current collector 13; The 20mm square 3240 epoxy phenolic resin plate is used as the anode end plate 20, and an anode groove 19 with a depth of 2mm is processed at the center of the anode end plate. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com