Chromium oxide/CNTS composite material and preparation and application thereof

A chromium oxide and composite material technology, which is applied to active material electrodes, electrodes of primary batteries, batteries of organic electrolytes, etc. Excellent, rate performance improvement, conductivity improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

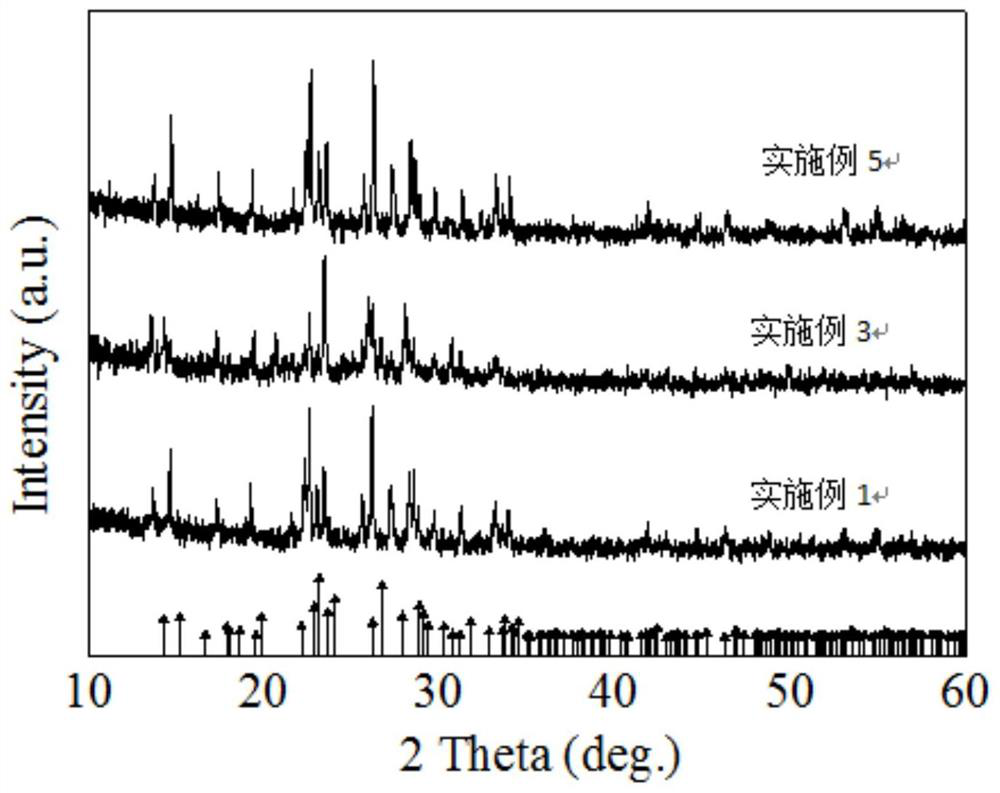

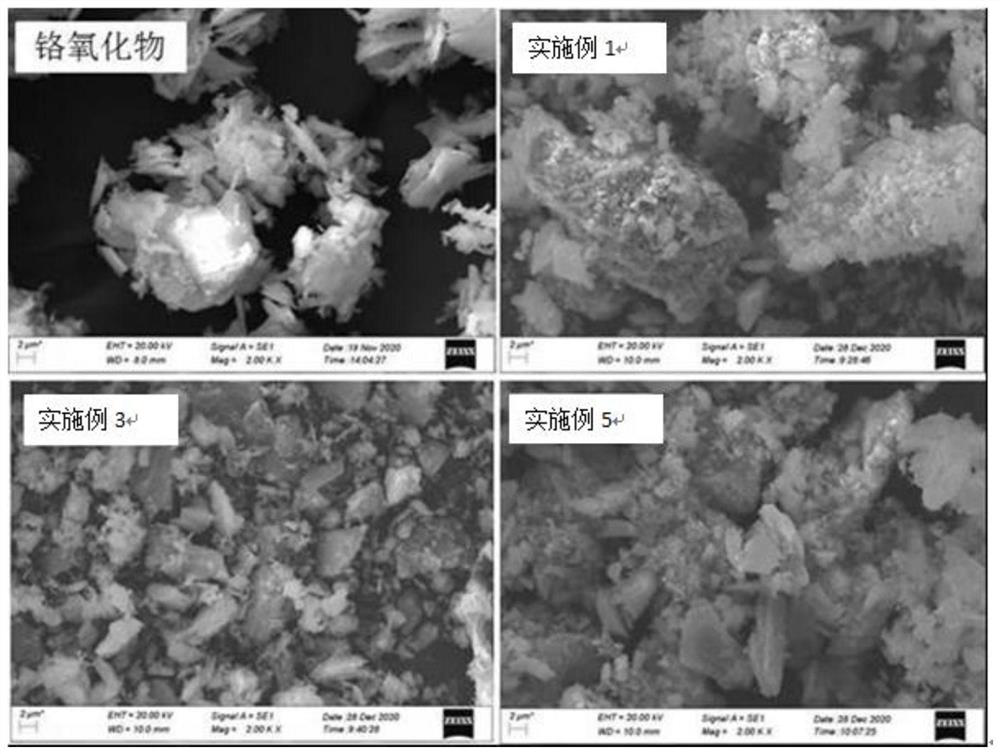

Embodiment 1

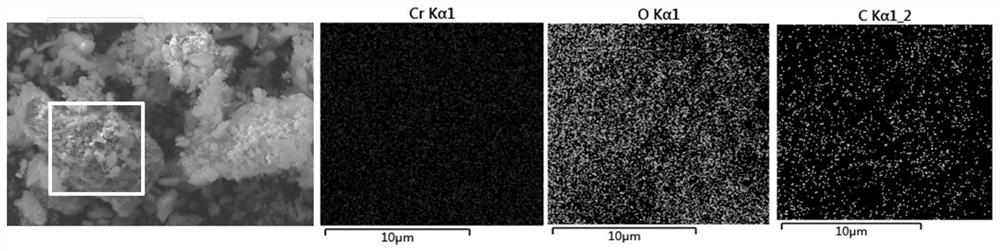

[0041] The method for preparing chromium oxide / CNTS composite material by high-temperature solid phase method comprises the following steps:

[0042] (1) Take 10g of chromium trioxide (CrO 3 ) placed in a porcelain boat, vacuum-dried at 50°C for 5 hours, put into a tube furnace for sintering, and heated to 260°C at a rate of 1°C / min under the protection of an oxygen atmosphere with an oxygen flow rate of 20mL / min. Sinter for 24 hours, transfer to a ball mill, ball mill for 5 hours at 200r / min, then pass through a 200-mesh sieve to obtain chromium oxide;

[0043] (2) Stir and mix chromium oxide and CNTS at a mass ratio of 20:1, put them into a muffle furnace for calcination, and after calcination at 200°C for 2 hours, grind to powder and pass through a 200-mesh sieve to obtain chromium oxide / CNTS composites.

Embodiment 2

[0045] The method for preparing chromium oxide / CNTS composite material by high-temperature solid phase method comprises the following steps:

[0046] (1) with embodiment 1 step (1);

[0047] (2) Stir and mix chromium oxide and CNTS at a mass ratio of 20:3, put them into a muffle furnace for calcination, and after calcination at 200°C for 2 hours, grind to powder and pass through a 200-mesh sieve to obtain chromium oxide / CNTS composites.

Embodiment 3

[0049] The method for preparing chromium oxide / CNTS composite material by high-temperature solid phase method comprises the following steps:

[0050] (1) with embodiment 1 step (1);

[0051] (2) Stir and mix chromium oxide and CNTS at a mass ratio of 20:1, put them into a muffle furnace for calcination, and after calcination at 270°C for 2 hours, grind to powder and pass through a 200-mesh sieve to obtain chromium oxide / CNTS composites.

PUM

| Property | Measurement | Unit |

|---|---|---|

| impedance | aaaaa | aaaaa |

| impedance | aaaaa | aaaaa |

| impedance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com