Preparation method of ruthenium-iridium-titanium ternary metal mesh electrode containing nano tip structure

A nano-tip and ternary metal technology, which is applied in chemical instruments and methods, water/sludge/sewage treatment, water/sewage treatment, etc., can solve problems such as affecting electrode activity and limiting application scenarios, so as to improve utilization rate, The effect of simple preparation process and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

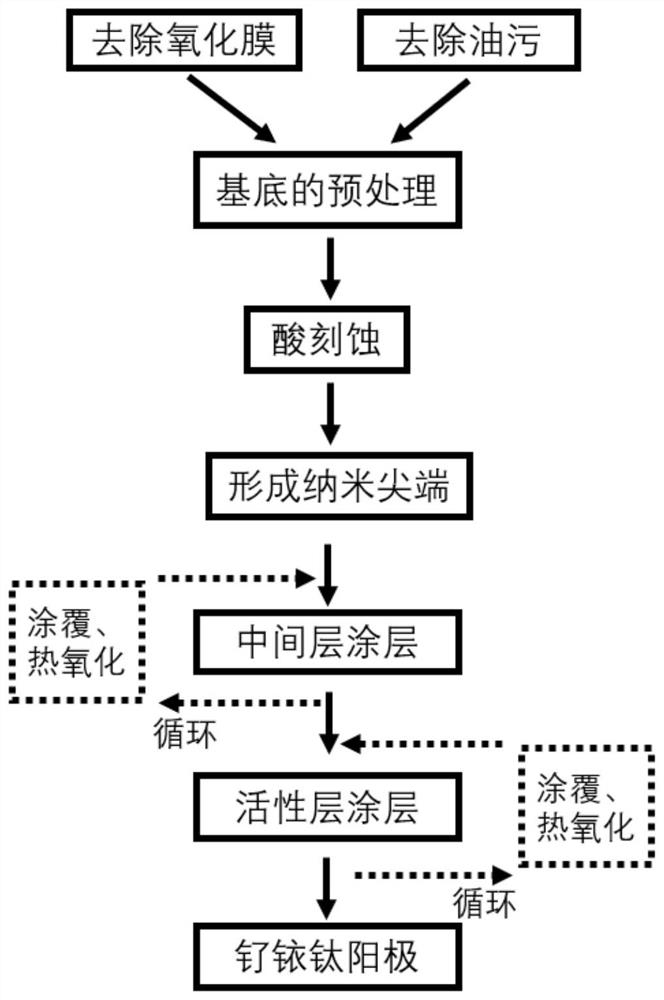

[0026] A method for preparing a ruthenium, iridium, and titanium ternary metal mesh electrode containing a nano-tip structure, the preparation steps of which are as follows:

[0027] (1) Pretreatment of the titanium screen substrate: put the titanium screen in a mixed acid solution containing hydrofluoric acid, nitric acid and high-purity water for 10 seconds to remove the oxide film on the surface, and then put the titanium screen in a mixed acid solution containing hydrofluoric acid, nitric acid and high-purity water The volume ratio is 1:4:5. Then, in a constant temperature water bath at 90° C., treat with 30% NaOH solution for 30 minutes to remove oil stains on the titanium substrate.

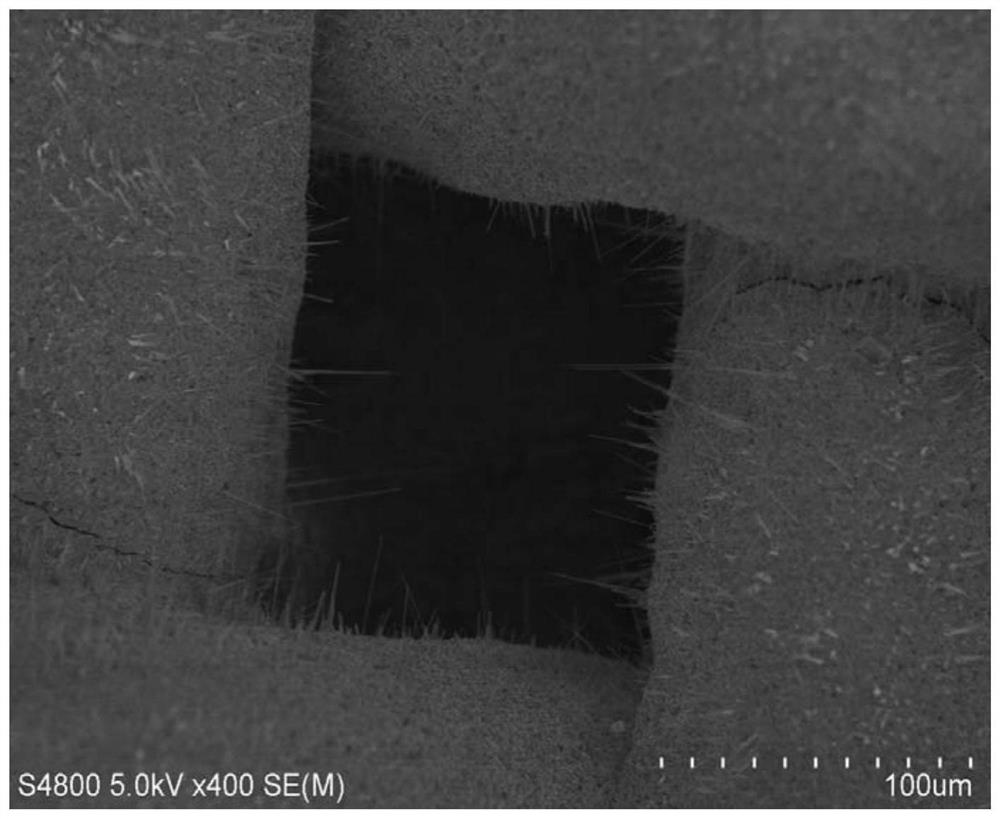

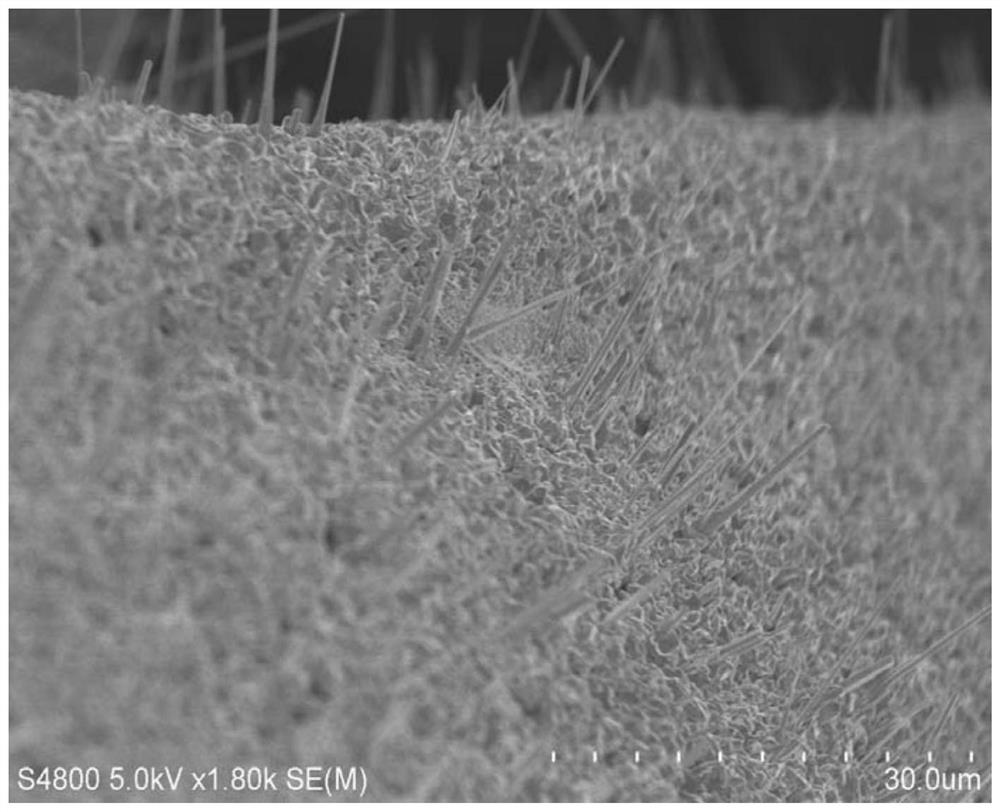

[0028] (2) Acid etching: Put the above-mentioned washed titanium mesh into an oxalic acid solution with a mass fraction of 10%, and etch it in a constant temperature water bath at 90°C for 1.5 hours. After the treatment, rinse the substrate with a large amount of water Oxalic acid and tita...

Embodiment 2

[0036] Comparing the performance of the ruthenium, iridium, titanium ternary metal mesh electrode with nano-tip structure and another ruthenium, iridium, titanium ternary metal mesh electrode for removing ammonium ions:

[0037] A preparation method of a ruthenium, iridium, titanium ternary metal mesh electrode containing a nano-tip structure, the preparation steps of which are the same as in Example 1; the preparation steps of another ruthenium, iridium, titanium ternary metal mesh electrode refer to the examples Steps 1, 2, 4, 5 in 1:

[0038] Use ruthenium, iridium and titanium ternary metal mesh electrodes as anodes to remove the ammonium ion concentration of 50mg / L wastewater (chloride ion concentration is 3g / L) prepared in the laboratory, and the working current is 300mA, in the flow-through electrochemical filter After 23 minutes of treatment, the concentration of ammonia nitrogen in the effluent was 23.5mg / L. Under the same conditions, the ruthenium, iridium and titan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com