Fine desulfurize method for carbon four components of refinery

A refinery carbon 4 and fine desulfurization technology, applied in separation methods, chemical instruments and methods, dispersed particle separation, etc. problem, to achieve the effect of increasing the anti-interference ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

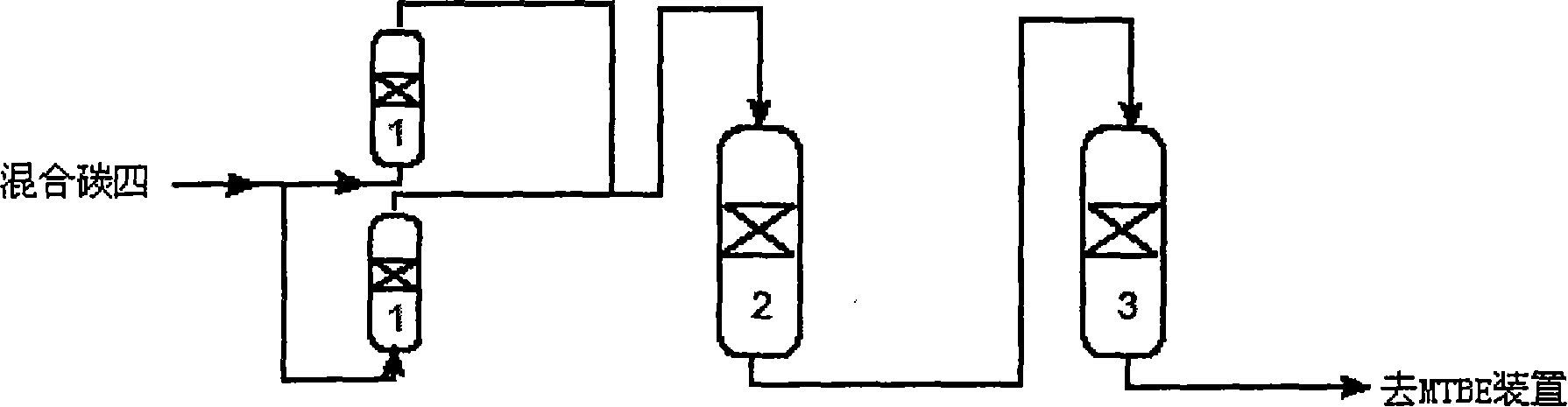

Embodiment 1

[0041] C4 raw material: normal temperature mixed C4 components from the refinery, the flow rate is about 12 tons / hour, and the total sulfur content is about 35mg / m 3 , where the COS content is about 21mg / m 3 , the content of methyl mercaptan is about 10mg / m 3 , the dimethyl disulfide content is about 3.7mg / m 3 , the content of thiophene is about 0.3mg / m 3 .

[0042] Desulfurization process: the mixed C4 raw material first enters two 3 The solid alkali crude stripping tower 1 of solid sodium hydroxide is used for crudely stripping sulfides such as carbonyl sulfide, mercaptan, sulfide, disulfide and thiophene in the mixed carbon four components. During the treatment process, the two towers can be operated intermittently; The mixed carbon four components after crude desulfurization enter into the interior 30m 3 The carbonyl sulfide adsorption reactor 2 of the carbonyl sulfide adsorbent absorbs and removes carbonyl sulfide and mercaptan in the mixed carbon four components; 3...

Embodiment 2

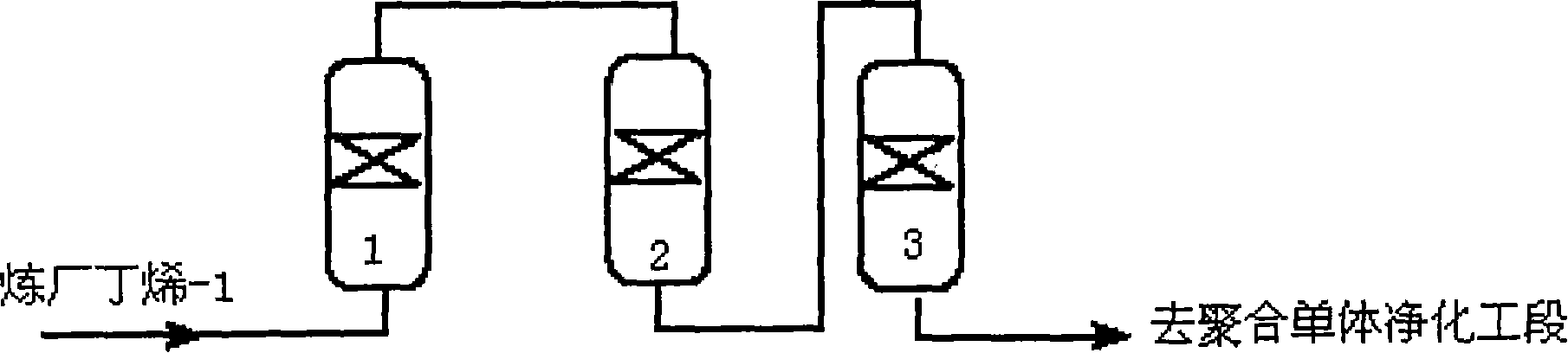

[0046] C4 raw material: butene-1 separated from petroleum liquefied gas in refinery, the flow rate is about 6 tons / hour, and the total sulfur content is about 11mg / m 3 , where the COS content is about 6.1mg / m 3 , the content of methyl mercaptan is about 3.9mg / m 3 , the content of ethanethiol is about 0.7mg / m 3 , the content of dimethylsulfide is about 0.3mg / m 3 .

[0047] Desulfurization process: Crude butene-1 enters the interior 15m 3 The solid alkali of massive potassium hydroxide is coarsely stripped tower 1, then enters and is equipped with 20m 3 The carbonyl sulfide adsorption reactor 2 of the carbonyl sulfide adsorbent finally enters the interior 20m 3 Fine desulfurization reactor 3 for fine desulfurizer.

[0048] The carbonyl sulfide adsorbent used in the above process is an adsorbent made of activated alumina impregnated with potassium salt, and the content of active component potassium (calculated as oxide) is about 8wt.%; the fine desulfurizer adopts activated...

Embodiment 3

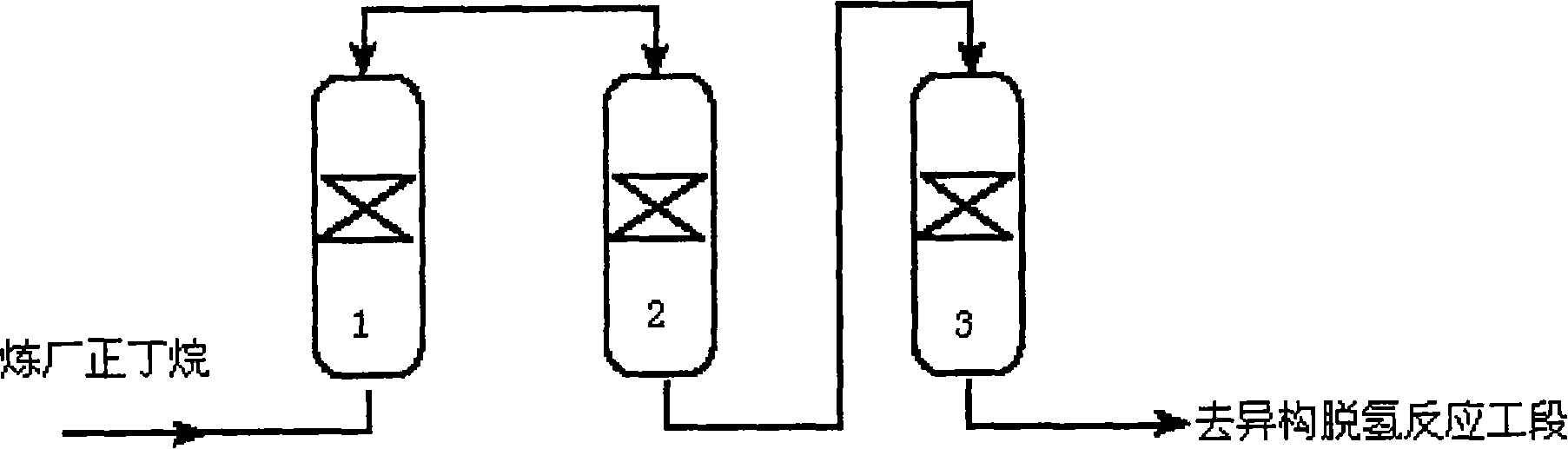

[0051] C4 raw material: n-butane separated from petroleum liquefied gas in refinery, the flow rate is about 3 tons / hour, and the total sulfur content is about 8mg / m 3 , where the COS content is about 6mg / m 3 , the content of methyl mercaptan is about 1.2mg / m 3 , the dimethyl disulfide content is about 0.5mg / m 3 , the content of thiophene is about 0.3mg / m 3 .

[0052] Desulfurization process: n-butane enters the interior 10m 3 The solid alkali of blocky sodium hydroxide and potassium hydroxide mixture is rough off tower 1, then enters and is equipped with 10m 3 The carbonyl sulfide adsorption reactor 2 of the carbonyl sulfide adsorbent finally enters the interior 10m 3 Fine desulfurization reactor 3 for fine desulfurizer.

[0053] The carbonyl sulfide adsorbent is made of activated alumina impregnated with sodium salt, and the sodium content of the active component (calculated as oxide) is about 7wt.%. The refined desulfurization adsorbent is made of alumina impregnated w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com