Configurations and methods of carbon capture

a carbon capture and carbon capture technology, applied in the field of acid gas removal, can solve the problems of increasing the energy consumption of the plant, all or almost all of these processes are expensive and energy-inefficient, and the process remains relatively expensiv

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

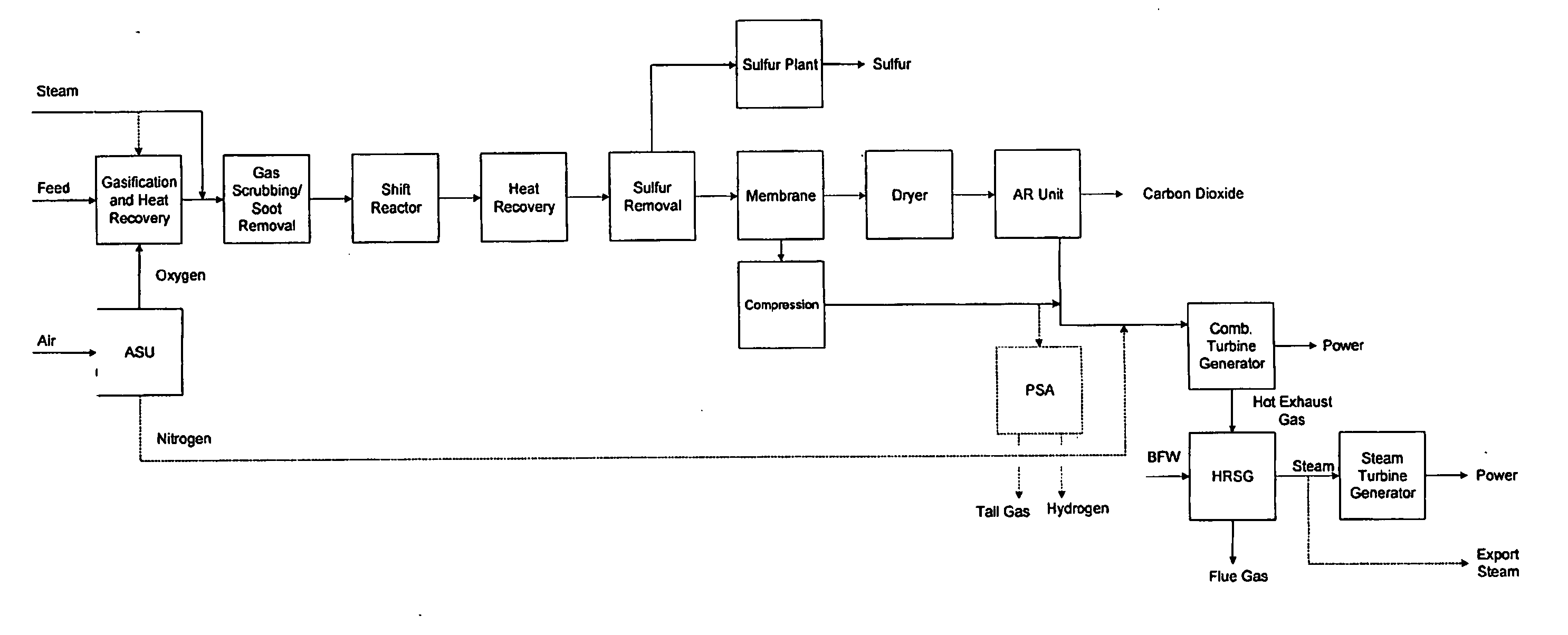

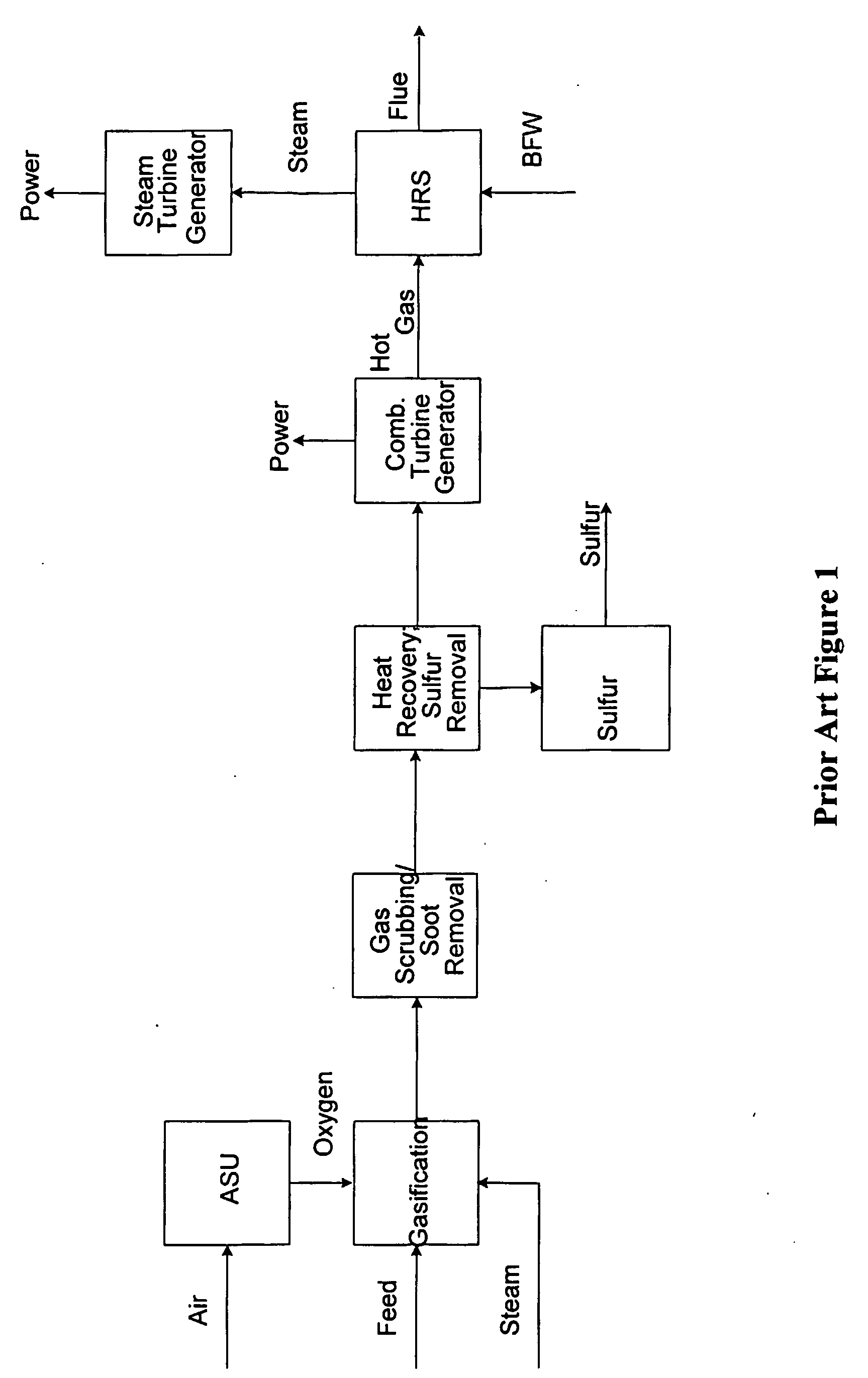

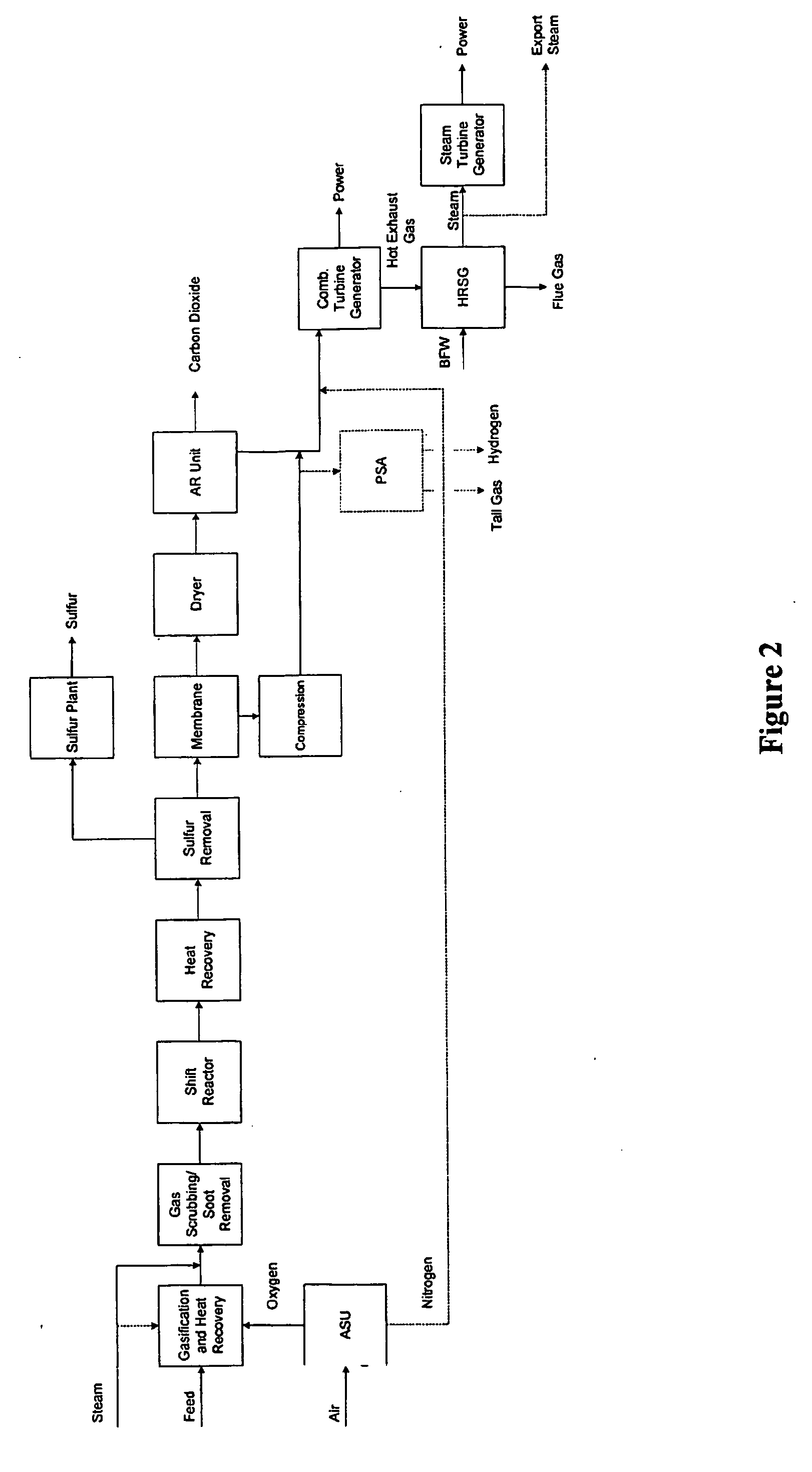

[0023] The inventors discovered that acid gases, and especially sulfur compounds and carbon dioxide can be effectively removed from a feed gas using autorefrigeration before the feed gas is combusted. Contemplated configurations advantageously reduce emission of pollutants that otherwise would have to be removed from flue gases at relatively low concentrations and pressure, thereby providing a more cost and energy efficient solution for decarbonization. In preferred configurations, the feed gas is IGCC syngas and the decarbonization is operationally coupled to sulfur removal from the feed gas before combustion of the processed syngas.

[0024] In a further preferred aspect of the inventive subject matter, syngas is conventionally formed using one or more gasification or partial oxidation units (typically using steam and oxygen), all of which are well known in the art. For example, suitable gasification reactors may include a reaction zone and a quench zone as described in U.S. Pat. No...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pressure | aaaaa | aaaaa |

| temperatures | aaaaa | aaaaa |

| pressure | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com