Method and device for simultaneously removing carbonyl sulfide and carbon disulfide

A carbon disulfide and carbonyl sulfide technology, applied in the field of carbon disulfide and carbonyl sulfide removal at the same time, can solve problems such as methods and devices that have not been reported, and achieve the effects of high automation, high integration, and improved utilization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

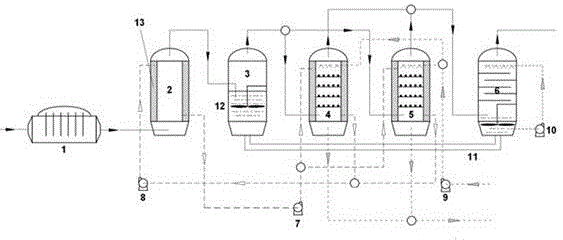

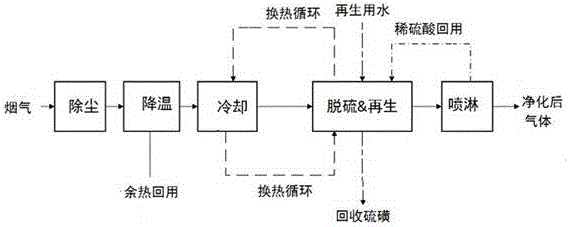

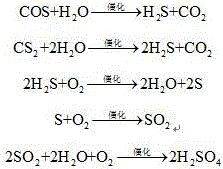

[0038] The method for simultaneously removing carbonyl sulfide and carbon disulfide described in this embodiment comprises the following steps:

[0039] (1) The high-temperature flue gas after pre-dust removal treatment is first cooled to 150°C through the waste heat boiler 1, and then heat exchanged through the cooling tower 2, so that the temperature of the flue gas is reduced to 60°C, and the cooling liquid is raised to 60°C.

[0040] (2) The cooled gas passes through the stripping tower 3, and the dilute sulfuric acid with a molar concentration of 0.01mol / L in the stripping tower 3 is brought into the fixed bed reaction tower I4 and the fixed bed reaction tower II5.

[0041] (3) The cooling liquid at 60°C after absorbing heat and heating up in step (1) flows into the heat exchange jackets of the fixed bed reaction tower I4 and the fixed bed reaction tower II5, and the fixed bed reaction tower I4 and the fixed bed reaction tower II5 The temperature of the internal catalyst ...

Embodiment 2

[0049] The method for simultaneously removing carbonyl sulfide and carbon disulfide described in this embodiment comprises the following steps:

[0050] (1) The high-temperature flue gas after pre-dust removal treatment is first cooled to 200°C through the waste heat boiler 1, and then heat exchanged through the cooling tower 2, so that the temperature of the flue gas is reduced to 80°C, and the cooling liquid is raised to 80°C.

[0051] (2) The cooled gas passes through the stripping tower 3, and the dilute sulfuric acid with a molar concentration of 0.06mol / L in the stripping tower 3 is brought into the fixed bed reaction tower I4 and the fixed bed reaction tower II5.

[0052] (3) The cooling liquid at 80°C after absorbing heat and heating up in step (1) flows into the heat exchange jackets of the fixed bed reaction tower I4 and the fixed bed reaction tower II5, and the fixed bed reaction tower I4 and the fixed bed reaction tower II5 The temperature of the internal catalyst ...

Embodiment 3

[0060] The method for simultaneously removing carbonyl sulfide and carbon disulfide described in this embodiment comprises the following steps:

[0061] (1) The high-temperature flue gas after pre-dust removal treatment is first cooled to 180°C through the waste heat boiler 1, and then heat exchanged through the cooling tower 2, so that the temperature of the flue gas is reduced to 95°C, and the cooling liquid is raised to 95°C.

[0062] (2) The cooled gas passes through the stripping tower 3, and the dilute sulfuric acid with a molar concentration of 0.1 mol / L in the stripping tower 3 is brought into the fixed bed reaction tower I4 and the fixed bed reaction tower II5.

[0063] (3) The cooling liquid at 95°C after absorbing heat and heating up in step (1) flows into the heat exchange jackets of fixed bed reaction tower Ⅰ4 and fixed bed reaction tower Ⅱ5, and the fixed bed reaction tower Ⅰ4 and fixed bed reaction tower Ⅱ5 The temperature of the internal catalyst was raised to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com