Purificant used for absorbing hydrogen sulfide and carbonyl sulfide in tail gas of natural gas and preparation method thereof

A technology for adsorbing natural gas and cleaning agents, applied in chemical instruments and methods, gas fuels, other chemical processes, etc., can solve the problems of low desulfurization accuracy and high desulfurization accuracy, and achieve the effect of simple composition, low use cost and good desulfurization effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Weigh 2.1g of zinc acetate containing two crystal waters, 2.4g of copper sulfate containing five crystal waters, and prepare a mixed solution with 100mL of water, then immerse 40g of activated carbon particles in the prepared mixed solution, and stir at room temperature for 4 hours. Dry at 80° C. for 6 hours to obtain particles loaded with active metal carriers. Immerse the particles loaded with active metal carriers in a mixed solution of 68%-70% nitric acid and 50% hydrogen peroxide until no more gas is generated. After the particles were filtered out, they were washed with distilled water to detect that the pH value was 5. Under the condition of drying temperature of 115° C., dry for 10 hours to obtain the finished cleaning agent. The active components of the cleaning agent: the mass percentage of zinc acetate is 1.5%, the mass percentage of copper sulfate is 1.5%; the mass percentage of the carrier is 97%.

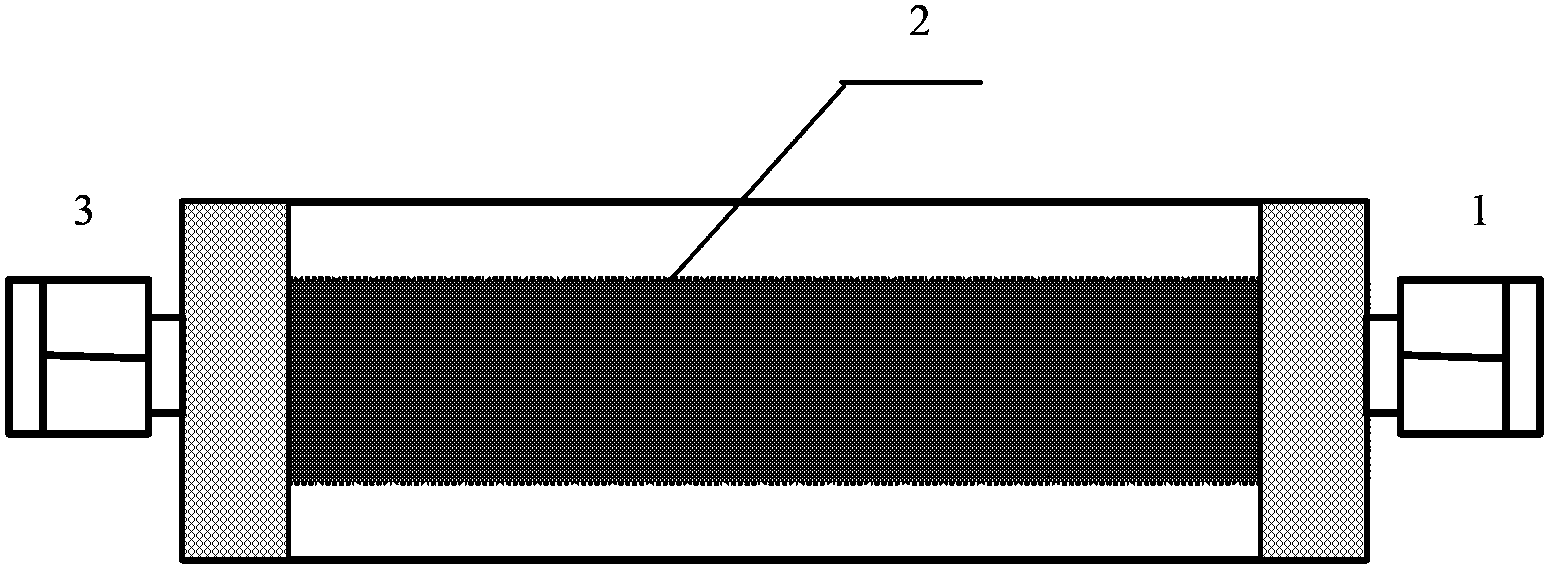

[0025] as attached figure 1 , put the cleaning agent 2 ...

Embodiment 2

[0027] Weigh 3.0g Zinc acetate Contains two crystal water, 4.6g copper nitrate It contains six crystal waters, and is mixed with 100mL water to make a mixed solution, then immerse 40g of activated carbon particles in the prepared mixed solution, and stir at room temperature for 6 hours. Dry at 70° C. for 8 hours to obtain particles loaded with active metal carriers. Immerse the particles loaded with active metal carriers in a mixed solution of 68%-70% nitric acid and 50% hydrogen peroxide until no more gas is generated. After the particles were filtered out, they were washed with distilled water to detect that the pH value was 5. Under the condition of drying temperature of 115° C., dry for 10 hours to obtain the finished cleaning agent. The active components of the cleaning agent: the mass percentage of zinc acetate is 2.2%, the mass percentage of copper nitrate is 2.5%; the mass percentage of the carrier is 95.3%.

[0028] as attached figure 1 , put the cleaning agent...

Embodiment 3

[0030] Weigh 3.7g of zinc nitrate containing six crystal waters, 3.8g of copper sulfate containing five crystal waters, and prepare a mixed solution with 100mL of water, then immerse 40g of activated carbon particles in the prepared mixed solution, and stir at room temperature for 4 hours. Dry at 80° C. for 6 hours to obtain particles loaded with active metal carriers. Immerse the particles loaded with active metal carriers in a mixed solution of 68%-70% nitric acid and 50% hydrogen peroxide until no more gas is generated. After the particles were filtered out, they were washed with distilled water to detect that the pH value was 5. Under the condition of drying temperature of 120° C., dry for 8 hours to obtain the finished cleaning agent. The active components of the cleaning agent: the mass percentage of zinc nitrate is 2.0%, the mass percentage of copper sulfate is 2.0%; the mass percentage of the carrier is 96.0%.

[0031] as attached figure 1 , put the cleaning agent 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com