Heat-treating methods and systems

a technology of heat treatment and workpiece, applied in the field of heat treatment methods and systems, can solve the problems of inability to heat treat workpieces, and high temperatures required to anneal the device side of semiconductor wafers, etc., to achieve the effect of reducing the magnitude of thermal gradients, and enhancing the cooling of the workpi

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

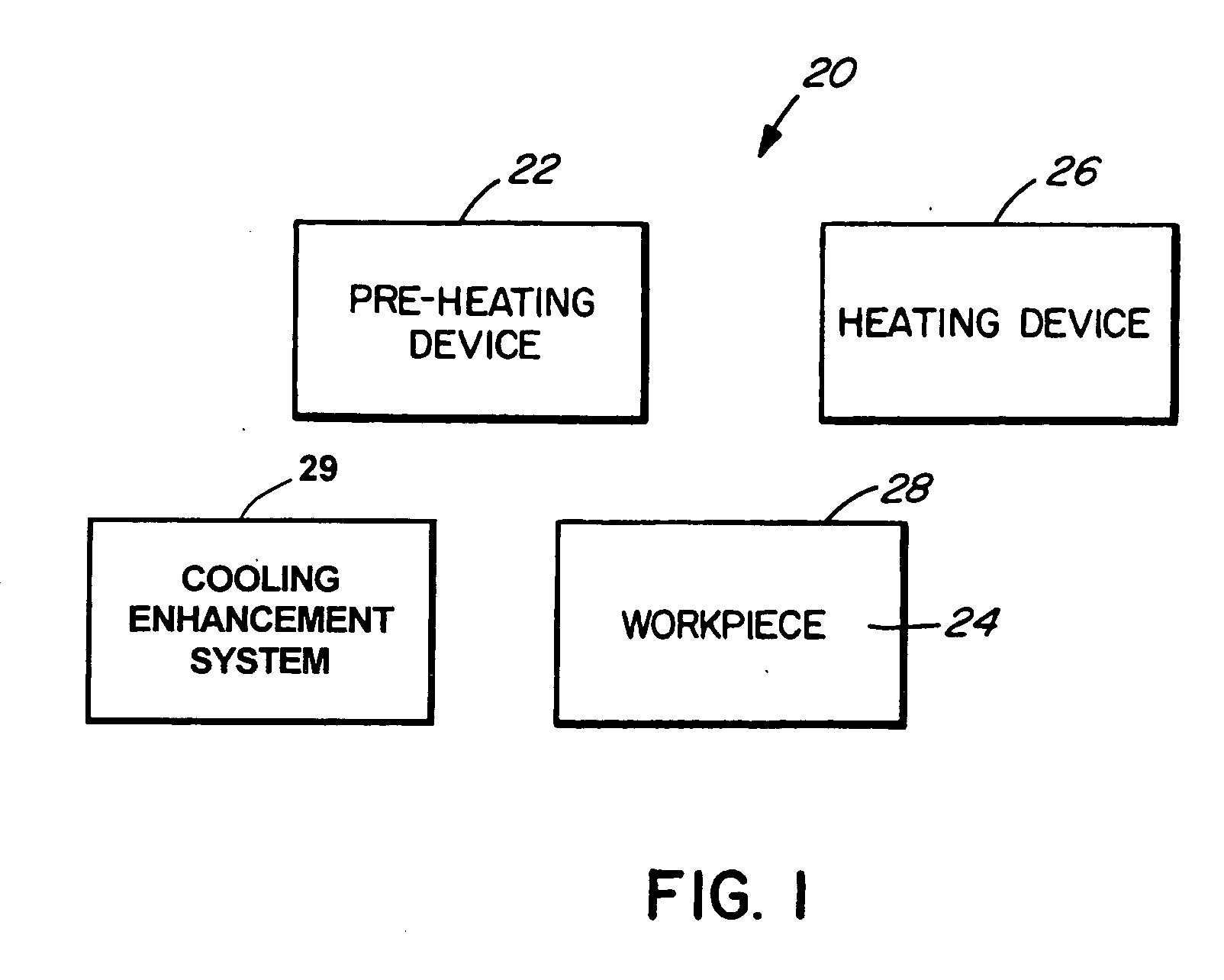

[0101] Referring to FIG. 1, a system for heat-treating a workpiece according to the invention is shown generally at 20. The system includes a pre-heating device 22 operable to pre-heat the workpiece 24 to an intermediate temperature, and a heating device 26 operable to heat a surface 28 of the workpiece to a desired temperature greater than the intermediate temperature. The system further includes a cooling enhancement system 29 for enhancing cooling of the workpiece to a temperature below the intermediate temperature.

[0102] System

second embodiment

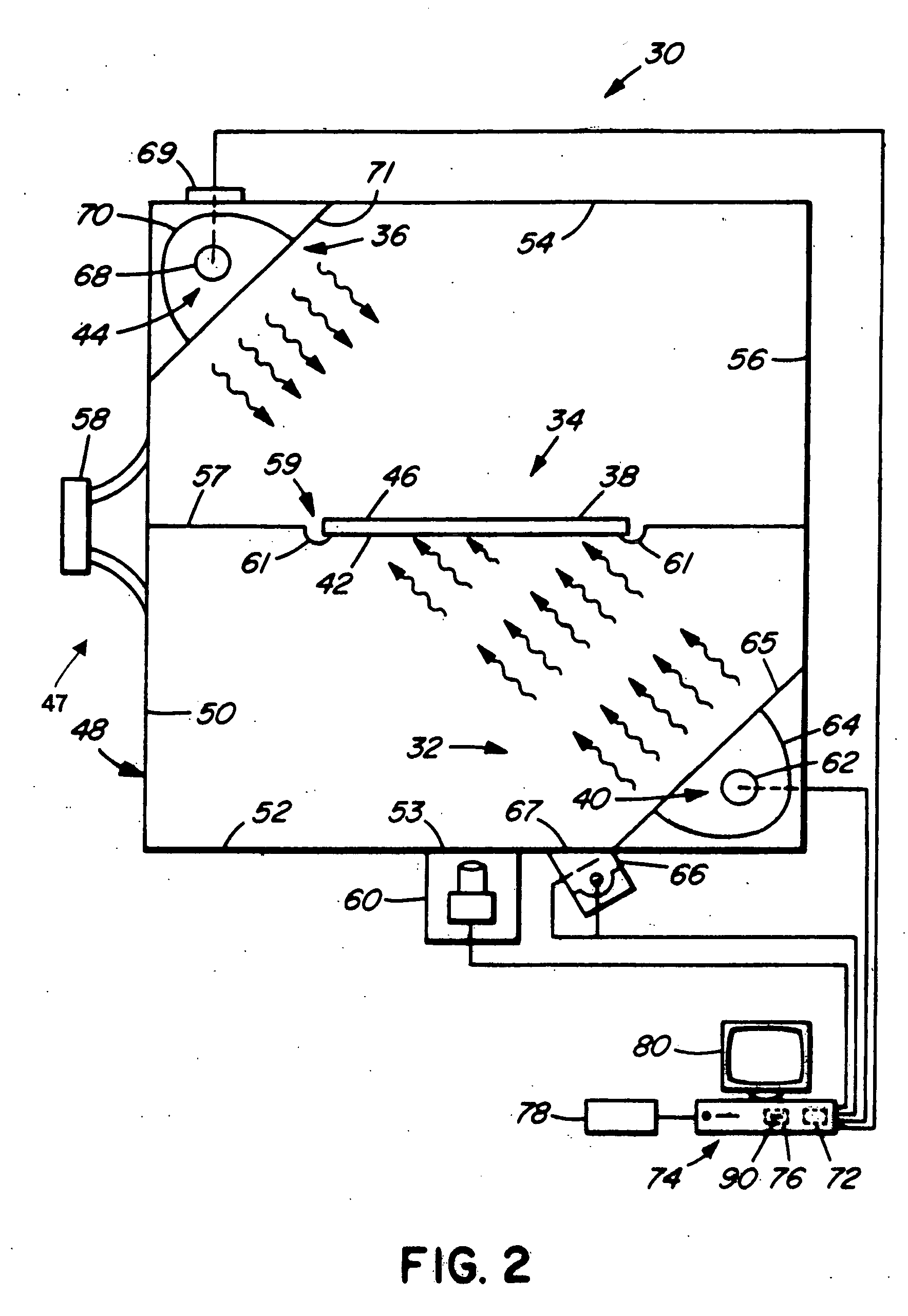

[0103] Referring to FIG. 2, a system for heat-treating a workpiece according to the invention is shown generally at 30. The system 30 includes a pre-heating device 32, operable to pre-heat a workpiece 34, which in this embodiment is a semiconductor wafer, to an intermediate temperature. The system further includes a heating device 36, which in this embodiment is operable to heat a surface 38 of the workpiece 34 to desired temperature greater than the intermediate temperature.

[0104] In this embodiment, the pre-heating device 32 is operable to pre-heat the workpiece 34 from an initial temperature to the intermediate temperature, and the heating device 36 is operable to heat the surface 38 of the workpiece 34 to the desired temperature, which is greater than the intermediate temperature by an amount less than or equal to about the difference between the intermediate and initial temperatures. In other words, a significant portion of the heating occurs during the heating from the initial...

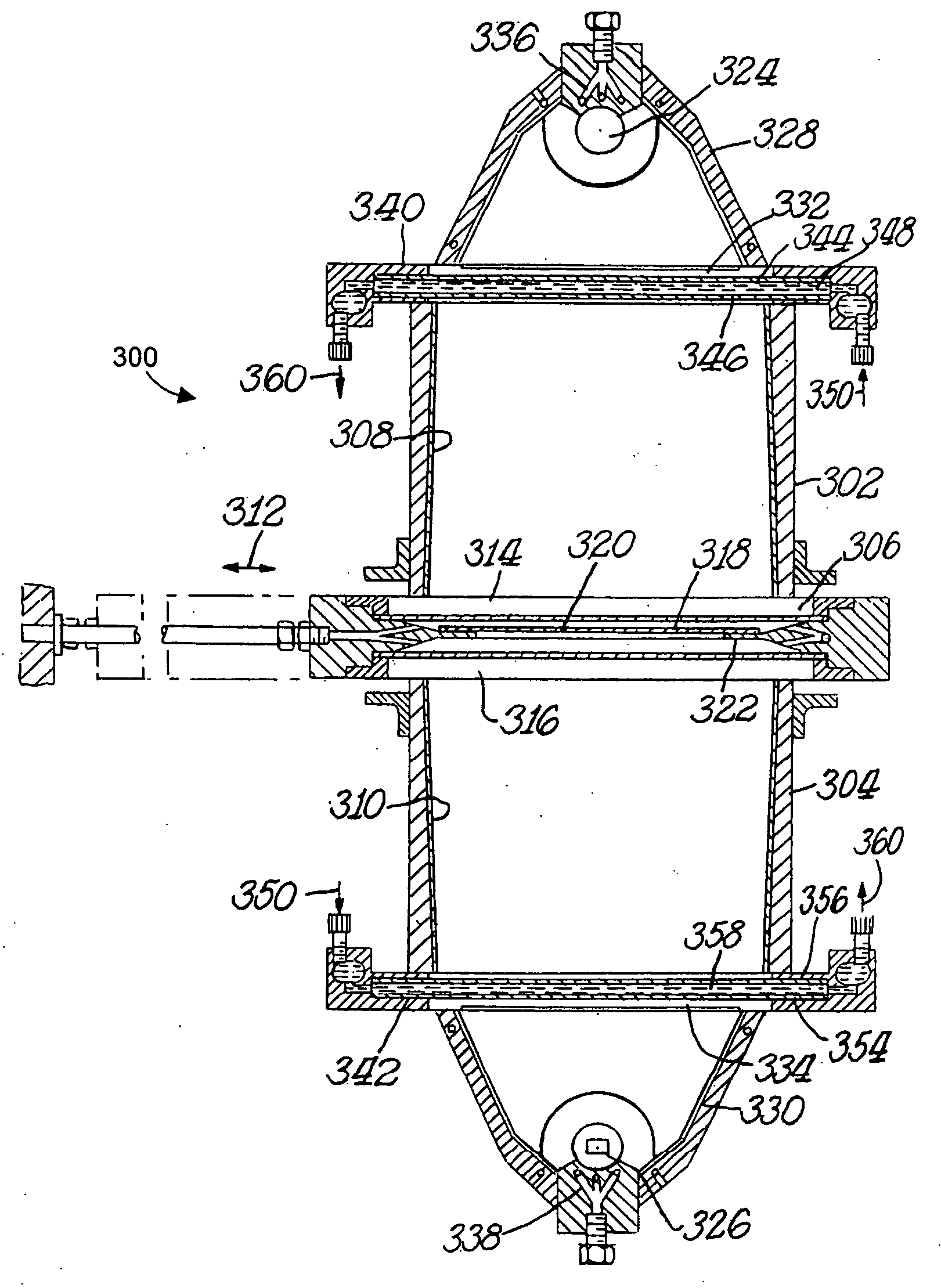

third embodiment

[0171] For example, referring to FIGS. 2 and 5, a system for heat-treating a workpiece according to the invention is shown generally at 200 in FIG. 5. In this embodiment, the pre-heating device 32 includes an alternative irradiance source, which in this embodiment includes at least one filament lamp. Thus, in this embodiment, irradiating the workpiece includes exposing the workpiece to electromagnetic radiation produced by at least one filament lamp. More particularly, in this embodiment the pre-heating device 32 includes a disc-shaped array 202 of tungsten filament lamps operable to project electromagnetic radiation through a quartz window 204 to irradiate the first side 42 of the workpiece 34, to pre-heat the workpiece to the intermediate temperature. Although there are numerous advantages to using an arc lamp rather than a tungsten filament lamp array as the pre-heating device 32, as discussed earlier herein, the deeper dopant diffusion that tends to result from tungsten filament...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| junction depths | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com