Combined-type residual heat recovery system suitable for internal combustion engine

A technology of waste heat recovery system and internal combustion engine, which is applied in the direction of internal combustion piston engine, combustion engine, mechanical equipment, etc., can solve the problems of complex system, large volume, low efficiency, etc., and achieve the effect of reducing complexity, ensuring efficiency and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

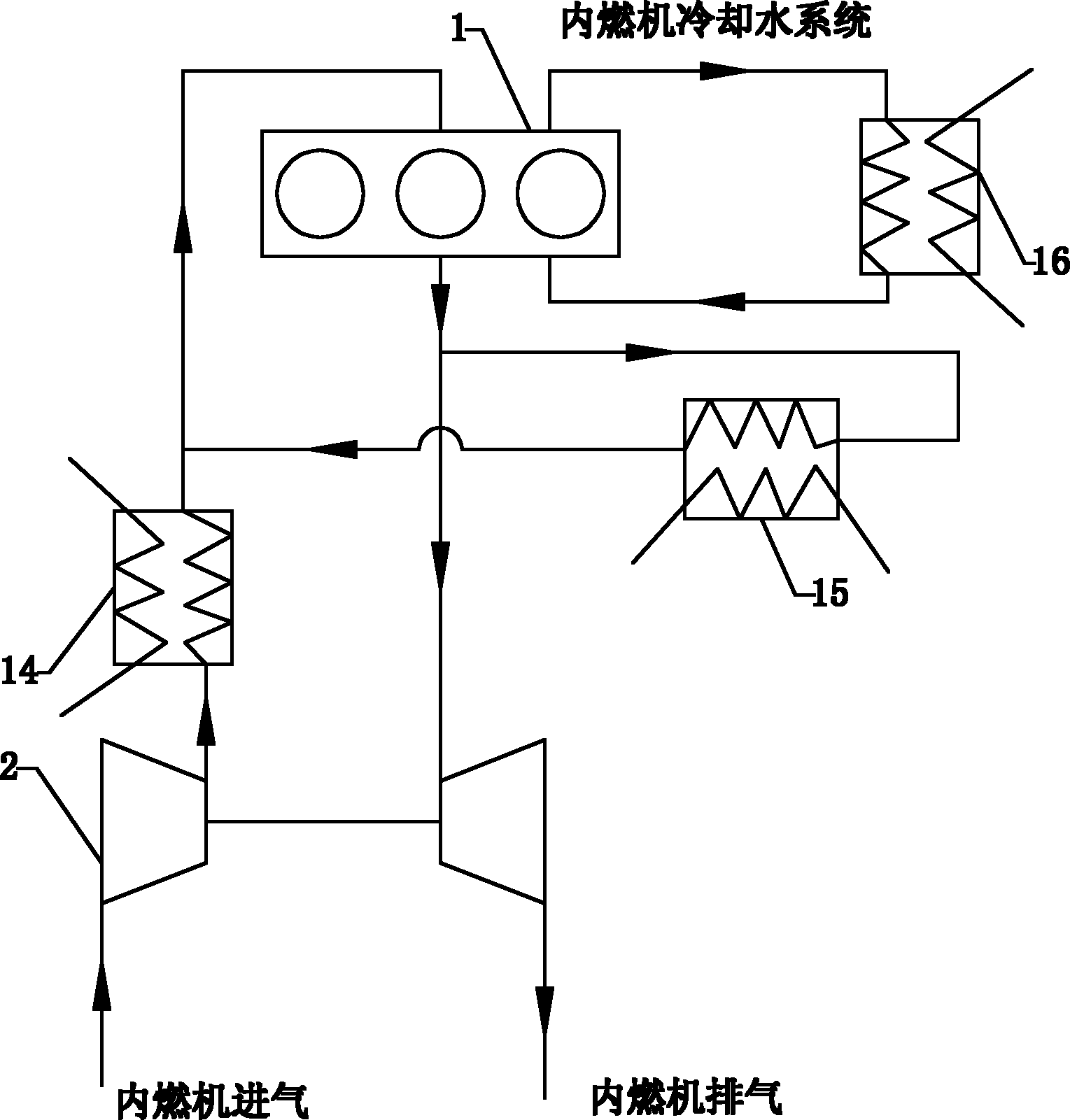

[0021] First, for figure 1 According to the analysis of the waste heat type of the internal combustion engine system shown, it can be known that the waste heat of the internal combustion engine is mainly distributed in the following parts:

[0022] ① Exhaust heat in the EGR cooler of the internal combustion engine;

[0023] ②Exhaust heat of the exhaust gas at the outlet of the turbine end of the internal combustion engine turbocharger;

[0024] ③ internal combustion engine cooling water heat;

[0025] ④The heat of the supercharged air at the outlet of the compressor end of the turbocharger of the internal combustion engine;

[0026] Among the waste heat mentioned above, ① and ② are medium-temperature waste heat, and ③ and ④ are low-temperature waste heat. If these different levels of energy can be recovered, the efficiency of the waste heat recovery system can be increased.

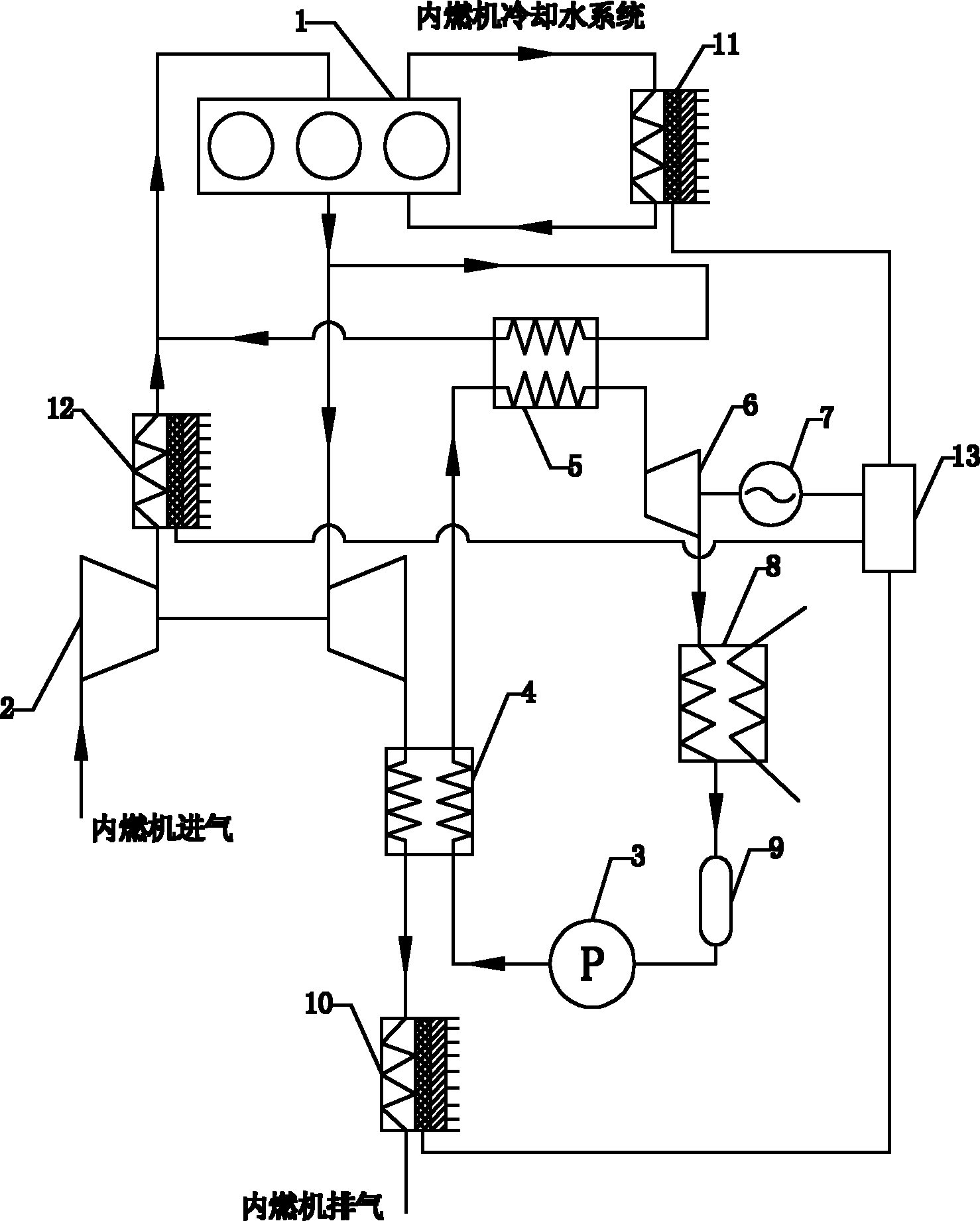

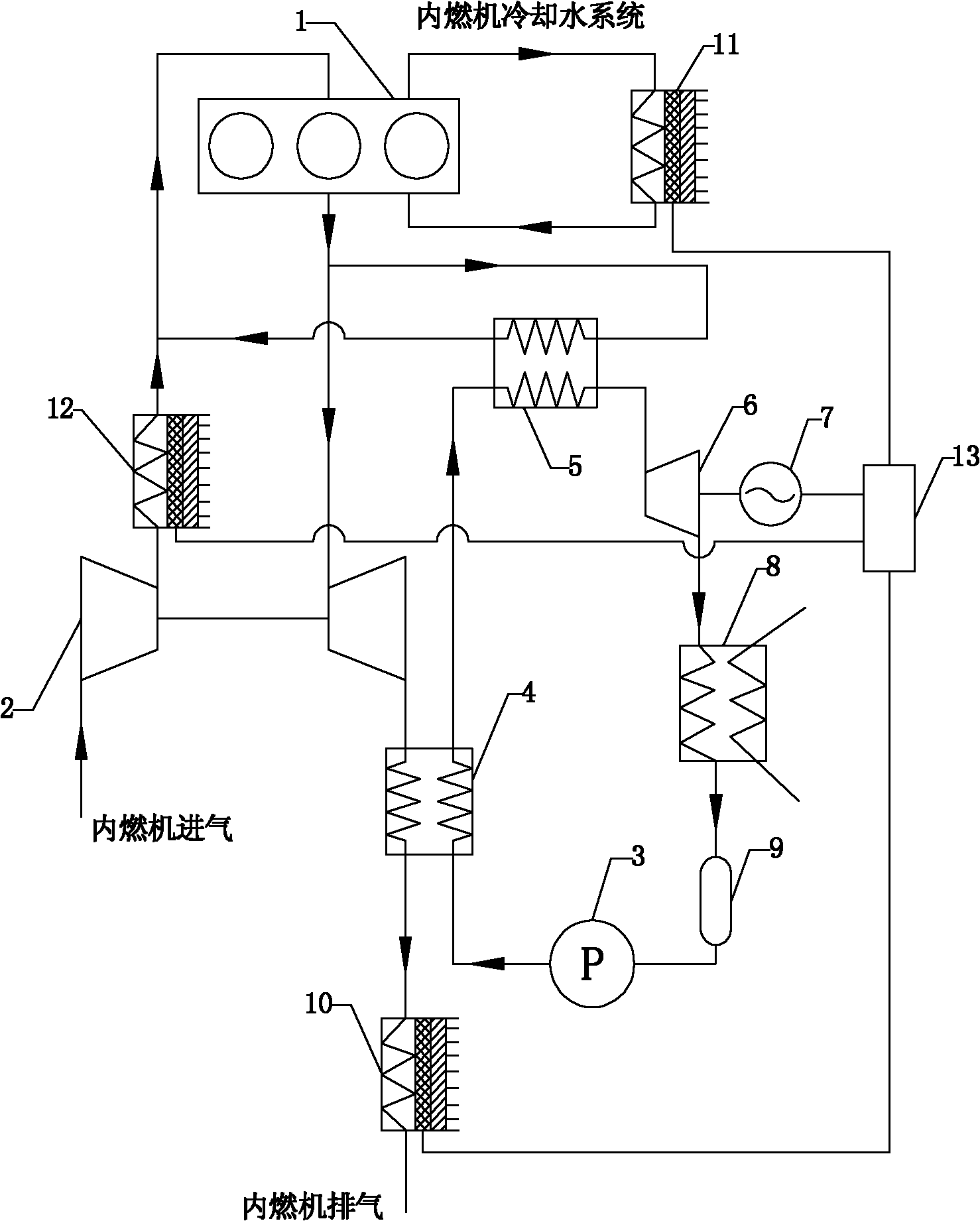

[0027] For this reason, the present invention aims at the characteristics of waste heat of interna...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com