Ultra-supercritical air energy storage/release system

An ultra-supercritical, air energy storage technology, used in gas turbine devices, machines/engines, mechanical equipment, etc., can solve the problems of large storage container volume, large irreversible losses, insufficient energy utilization, etc., and achieve broad application prospects and environmental protection. Friendly, land- and resource-efficient effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

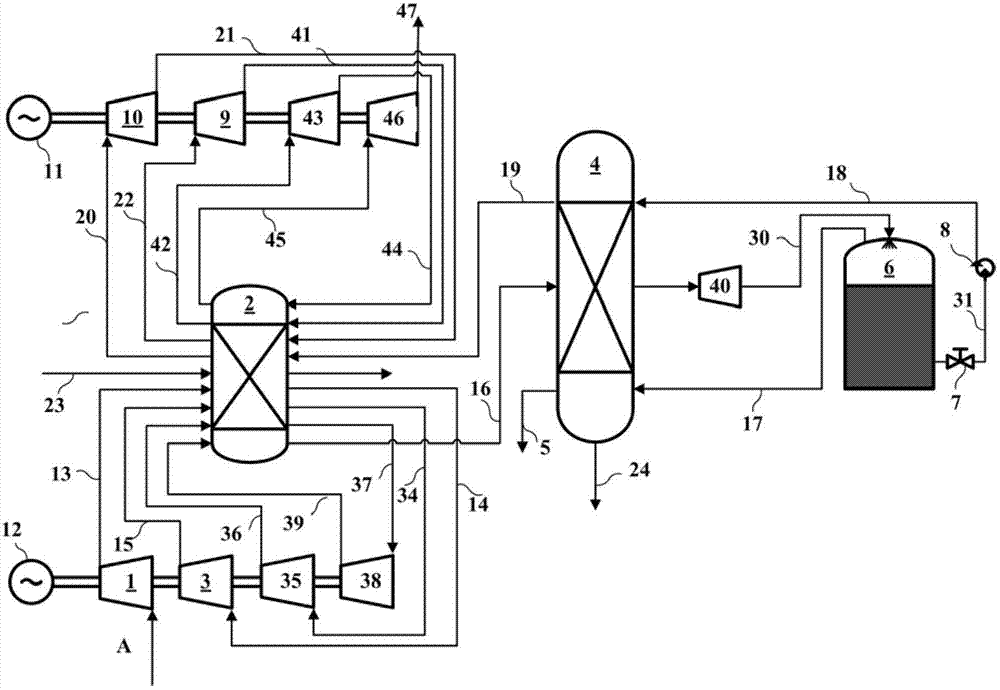

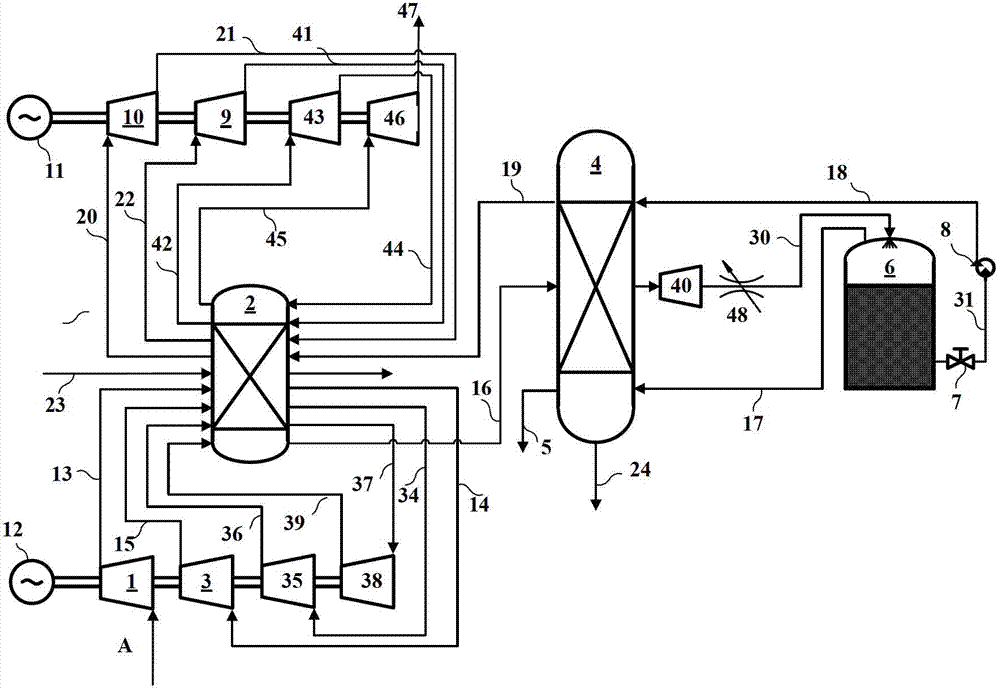

[0036] figure 1 It is Embodiment 1 of the ultra-supercritical air energy storage / energy release system of the present invention. Including low-pressure compressors 1, 3, heat storage / heat exchanger 2, high-pressure compressors 35, 38, expander 40 (at least one stage), cold storage / heat exchanger 4, cryogenic storage tank 6, valve 7, cryopump 8 , high-pressure turbines 9, 10, low-pressure turbines 43, 46, generator 11, drive motor 12, pipelines 13, 14, 15, 16, 17, 18, 19, 20, 21, 22, 23, 24, 30, 31, 34, 36, 37, 39, 41, 42, 44, 45, etc., and Air A.

[0037] The driving motor 12 is affixed to the common transmission shafts of the compressors 1, 3, 35, 38, and the common transmission shafts of the generator 11 and the turbines 9, 10, 43, 46 are affixed. Low-pressure compressors 1 and 3 are connected to heat storage / heat exchanger 2 through pipelines 13, 14 and 15, and high-pressure compressors 35 and 38 are connected to heat storage / heat exchanger 2 through pipelines 34, 36, 37 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com