Process line control apparatus and method for controlling process line

a technology of process line and control apparatus, which is applied in the direction of heat treatment apparatus, lighting and heating apparatus, furniture, etc., can solve the problems of high noise and difficulty in the current techniques to measure the crystal grain size of steel materials moving at such a high speed, and achieve the effect of improving the quality of steel materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

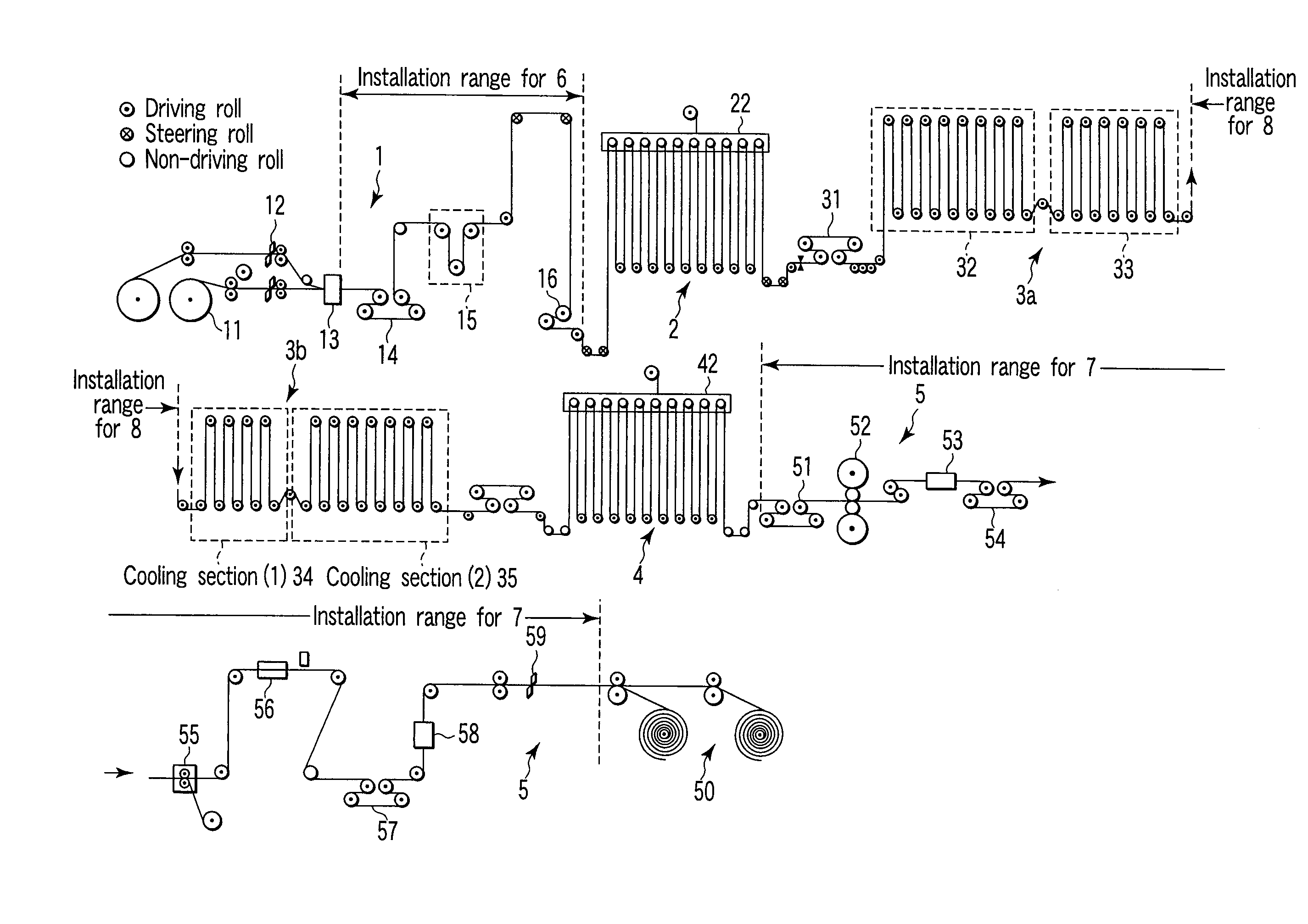

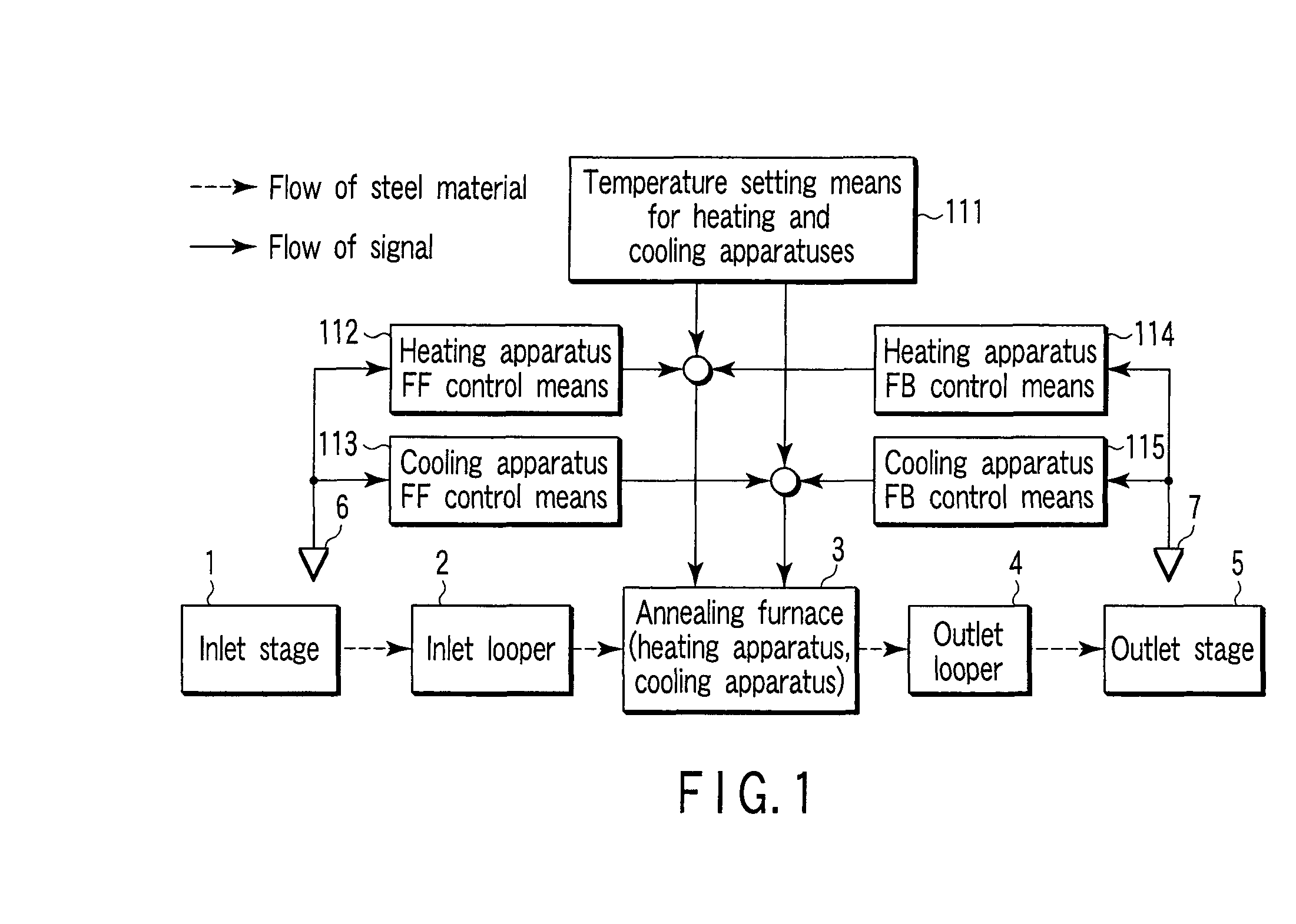

[0041]FIG. 1 is a block diagram illustrating a first embodiment in accordance with the present invention. As described above, the CAL is composed of roughly five stages, an inlet stage 1, an inlet looper 2, an annealing furnace (hereinafter simply referred to as a furnace) 3, an outlet looper 4, and an outlet stage 5. The furnace 3 is composed of a heating apparatus and a cooling apparatus, the heating apparatus being located upstream of the cooling apparatus. However, depending on a set temperature for each section in the furnace 3, the cooling apparatus may be a temperature holding apparatus. For the set temperature for each section in the furnace 3, temperature setting means 111 for the heating and cooling apparatuses preset, for example, temperature set values of 800° C. for the heating apparatus and 300° C. for the cooling apparatus.

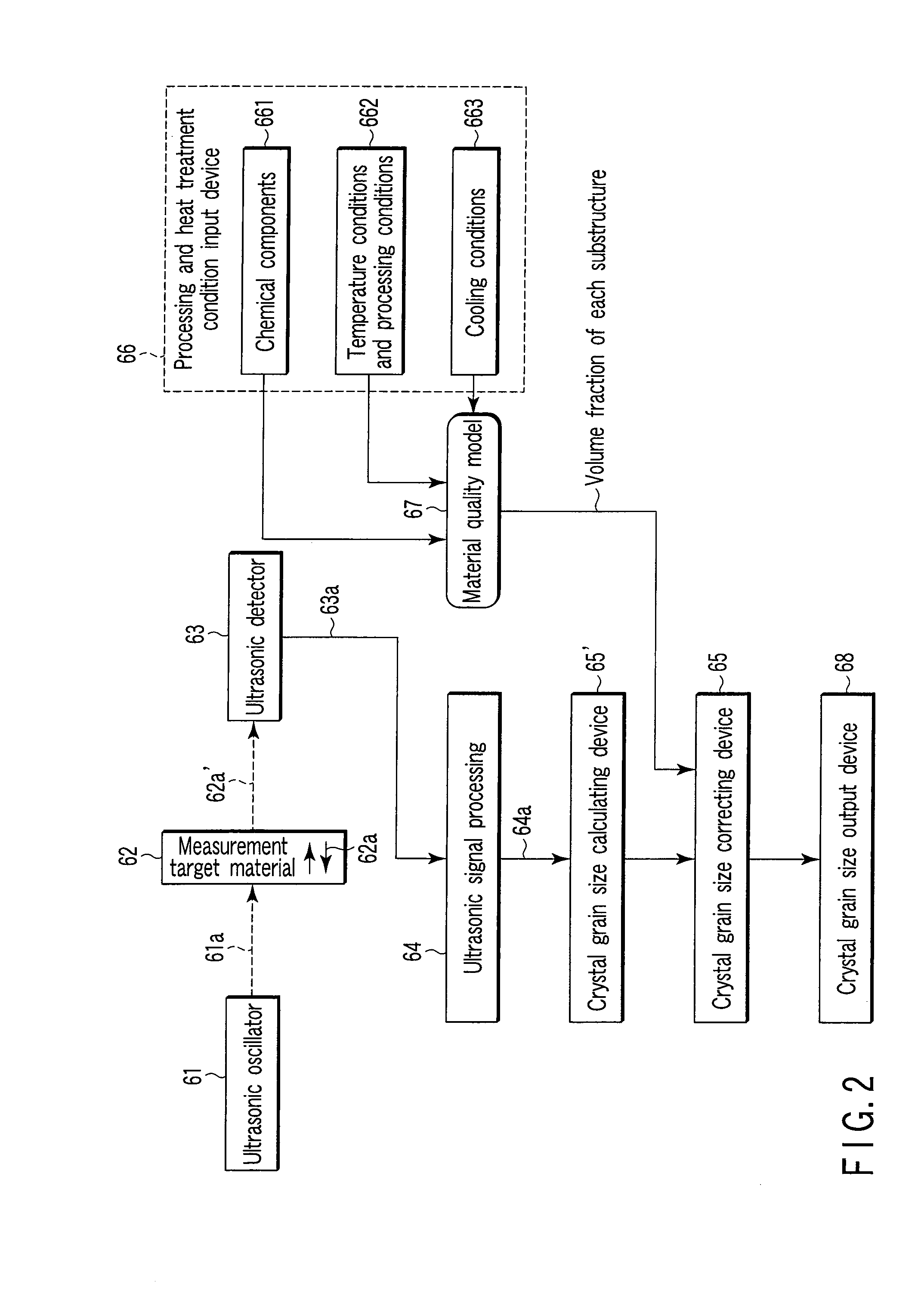

[0042]Material quality measuring apparatuses 6, 7 described below are arranged in the inlet stage 1 and the outlet stage 5, respectively. Specifica...

second embodiment

[0093]FIG. 7 is a block diagram illustrating a second embodiment in accordance with the present invention. FIG. 7 differs from FIG. 1 in that the single furnace 3 is divided into a furnace 3a having a heating apparatus and a furnace 3b having a cooling apparatus, with a material quality measuring apparatus 8 installed in the divided portion, specifically at an appropriate position between the soaking section 33 and the cooling section (1)34, shown in FIG. 6, so as to allow the temperatures of the heating and cooling apparatuses in the furnaces to be controlled as follows. Specifically, the material quality measuring apparatus 8 measures the quality of the steel material. On the basis of the measurement results for the quality of the steel material, corrections are made of the temperatures of the heating apparatus (intermediate control means) 116 in the furnace 3a and the cooling apparatus (intermediate control means) 117 in the furnace 3b.

[0094]The second embodiment configured as d...

third embodiment

[0095]FIG. 8 is a block diagram illustrating a third embodiment in accordance with the present invention.

[0096]Speed setting means 118 sets the conveyance speed for the steel material in the furnace 3 at a set value of, for example, 10 m / s.

[0097]The material quality measuring apparatuses 6, 7 are arranged in the inlet stage 1 and outlet stage 5, respectively. Measurements are made of the quality of the steel material, specifically, the crystal grain size and r value of the steel material before the material is carried into the furnace 3 and while the material is being carried out of the furnace 3.

[0098]A measurement result from the material quality measuring apparatuses 6 is input to heating apparatus feed-forward (FF) control means 122. On the basis of the measurement result from the material quality measuring apparatus 6, the heating apparatus feed-forward (FF) control 122 means determines that it is proper to set the conveyance speed for the steel material in the furnace 3 at, fo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| speed | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com