Method for environment-friendly low-temperature scouring and bleaching in spinning dyeing and finishing

A technology for textile dyeing and finishing, low-temperature scouring and bleaching auxiliaries, applied in textiles and papermaking, bleaching products, fiber processing and other directions, can solve the problems of unspecified specific composition and proportion of activator, failure to achieve one bath of scouring and bleaching, and high dosage cost. , to achieve the effect of reducing the overall cost, saving processing time, and reducing the degree of damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Developed low temperature technology and application effect:

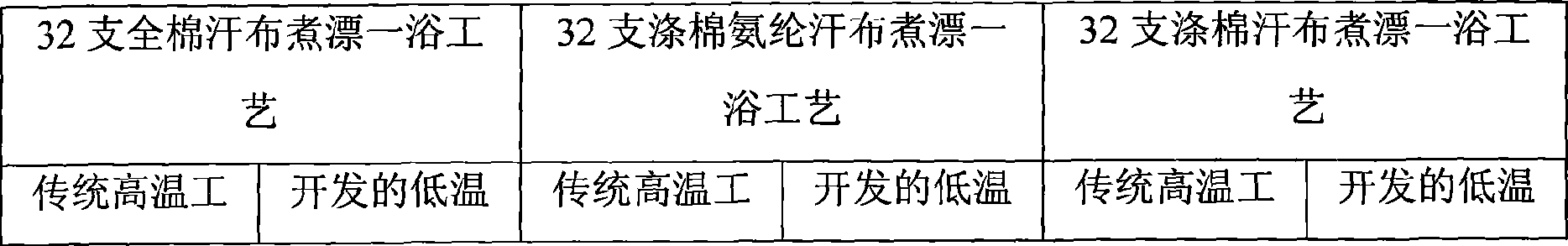

[0034] 1. Traditional scouring and bleaching high-temperature process and the developed low-temperature process using low-temperature scouring and bleaching auxiliary composition

[0035]

[0036]

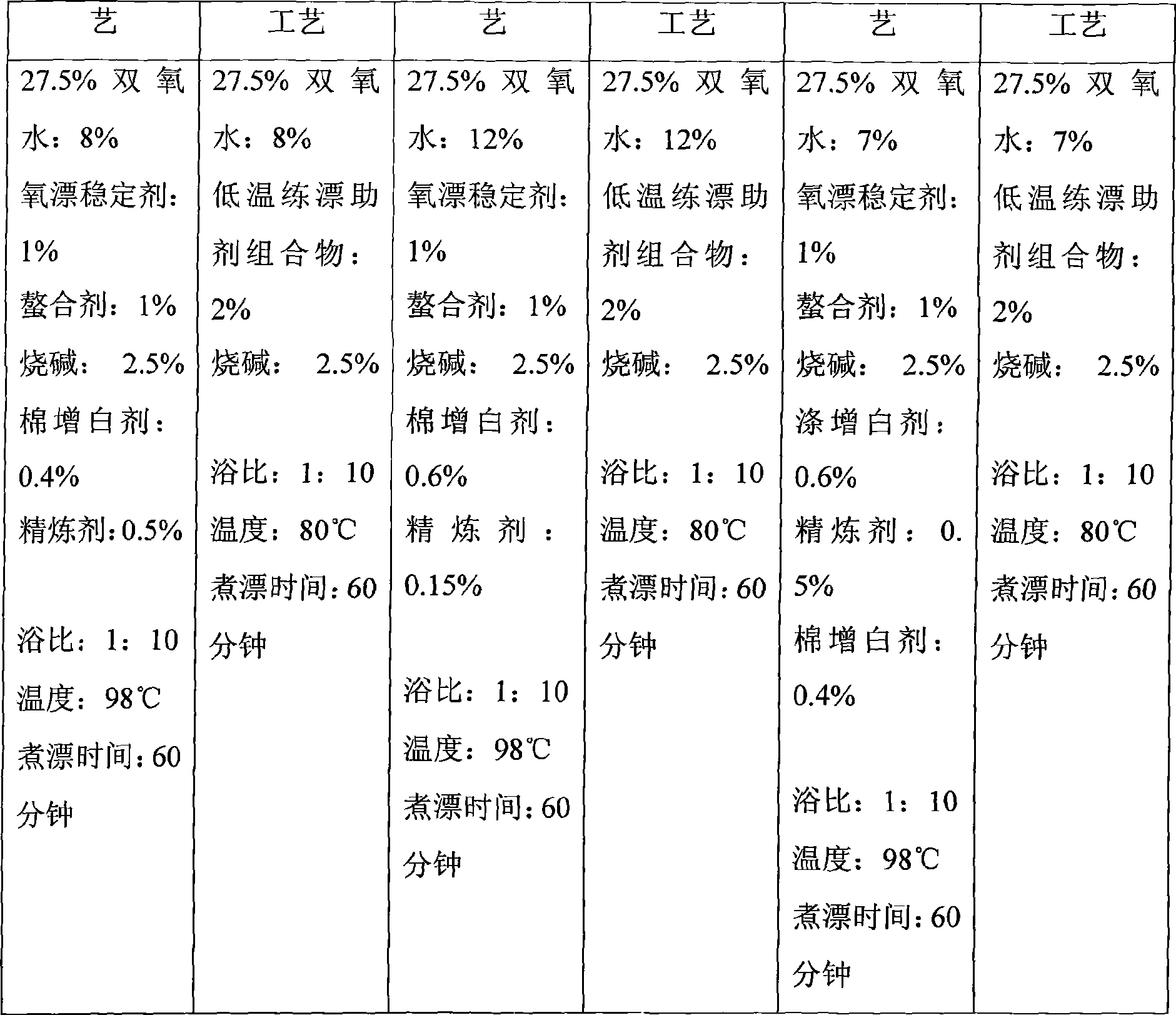

[0037] 2. Application effect comparison

[0038]

[0039]

[0040]

[0041]

[0042] Note: ①Traditional: for the traditional high temperature process

[0043] ② Data of 4 times of developed low-temperature process: 4 times of test data of low-temperature process using the developed one-dose solid additive composition

[0044] ③Capillary effect (capillary effect): measured according to F2 / T01071 standard, unit: cm / 30min.

[0045] ④ Whiteness: measured according to GB / T8424.2-2001 standard, instrument: Hunterlab.ULTRA.SCAN X color measuring and matching instrument

[0046] ⑤ Bursting strength: measured according to GB / T14800-93 standard, instrument: YG(B)031T strength tester produced by Wenzhou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com