Closed loop control method of sintering mixture moisture

A closed-loop control, mixing technology, applied in the direction of adaptive control, general control system, control/regulation system, etc., can solve problems such as automatic control not seen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

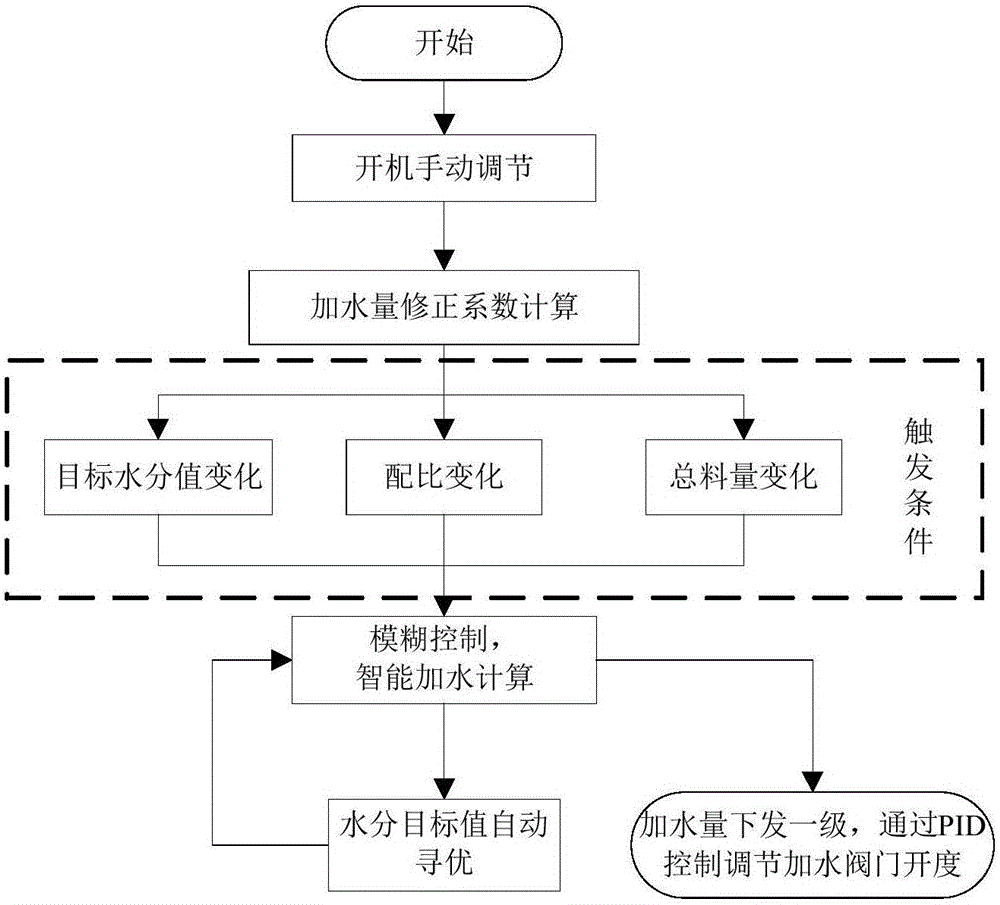

[0072] In order to make the above-mentioned features and advantages of the present invention more obvious and understandable, the present invention will be further described in detail below in conjunction with specific examples:

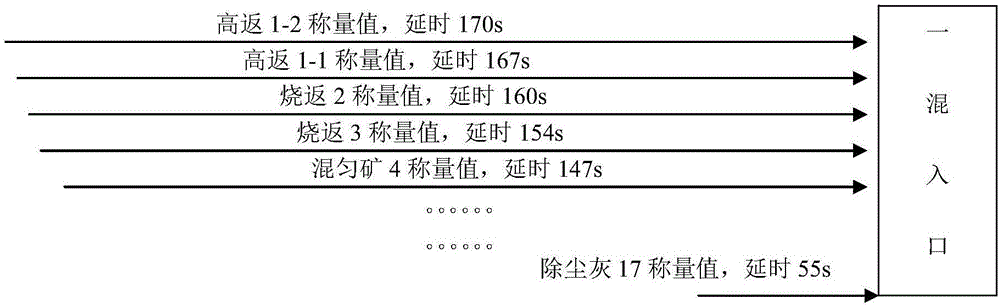

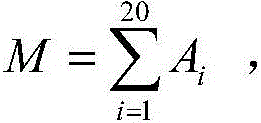

[0073] Step1: Data collection: the actual feeding amount of the feeding port of each raw material bin, the target moisture value, the moisture content value of each material, the detection value of the microwave water meter after the first mixing, the flow value of the first mixing water pipe, the amount of water added to the batching room, sintering Machine speed, left flue temperature, right flue temperature, end point temperature, the sampling period is 1min. According to the upper and lower limits of each data value, the validity of the data is judged.

[0074] Step2: Start-up adjustment: After the sintering machine is turned on, set the target moisture value of the mixture to 6.3, first adjust the opening of the main valve of the first mixing wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com