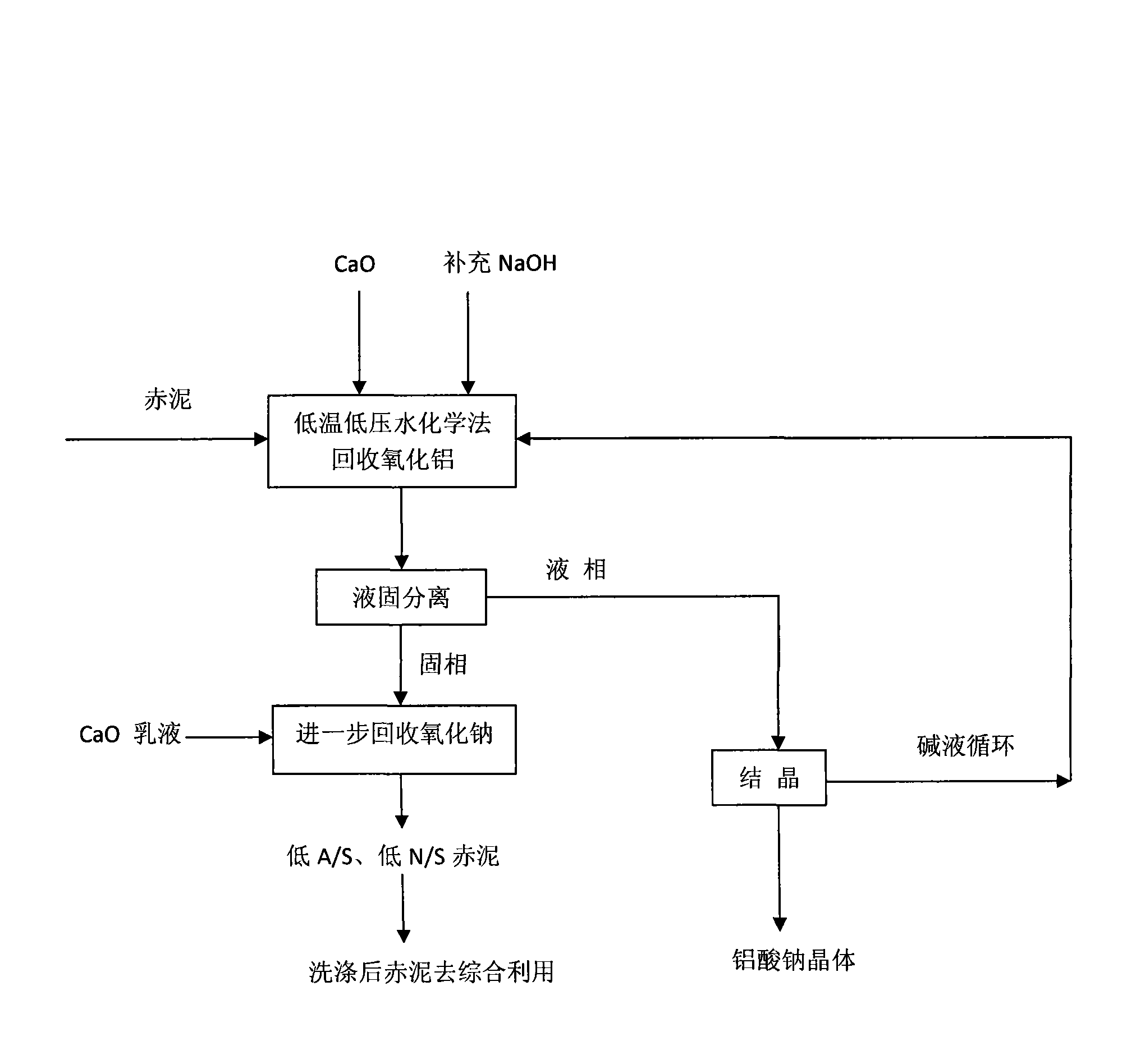

Low-temperature low-pressure hydro chemical method for recovering aluminum oxide and sodium oxide from red mud

A low-temperature, low-pressure, alumina technology, applied in the direction of alumina/aluminum hydroxide, alkali metal oxides, etc., can solve the problems of difficult industrial operation, high energy consumption of calcium oxide, and high equipment investment, so as to improve resource utilization, Excellent operability and high recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

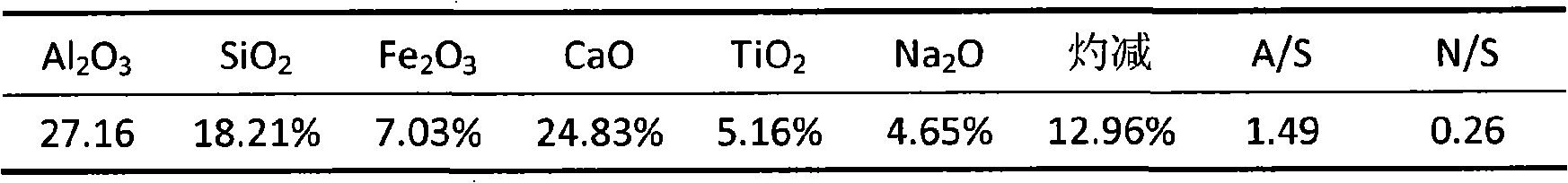

[0018] Using Bayer process red mud as raw material, aluminum oxide and sodium oxide are recovered by low-temperature and low-pressure hydrochemical method. The composition (wt%) of the red mud used in the Bayer process is as follows:

[0019]

[0020] The specific processing steps are as follows:

[0021] 1. Take a certain amount of red mud and add it to the NaOH solution with a mass percentage concentration of 50%. The mass ratio of NaOH to red mud is 4:1. After mixing evenly, transfer it to the reaction kettle, adjust the stirring speed, and set the temperature control program. , raise the temperature of the reactor to 220°C to react for 4 hours, and then turn on the cooling water to complete the reaction; filter the reaction slurry while it is hot, separate the liquid and solid, and use the red mud filter cake for later use. Take 10g of red mud filter cake, wash at 95°C and dry at 120°C, analyze its composition (wt%), the results show that Al in red mud 2 o 3 Content ...

Embodiment 2

[0025] Using Bayer process red mud as raw material, aluminum oxide and sodium oxide are recovered by low-temperature and low-pressure hydrochemical method. The composition (wt%) of the red mud of the Bayer process used is the same as that of Example 1.

[0026] The specific processing steps are as follows:

[0027] 1. Take a certain amount of red mud and add it to the NaOH solution with a mass percentage concentration of 50%. The mass ratio of NaOH to red mud is 3:1. After mixing evenly, transfer it to the reactor, adjust the stirring speed, and set the temperature control program. , raise the temperature of the reactor to 230°C for 3.5 hours, and then turn on the cooling water to complete the reaction; filter the reaction slurry while it is hot, separate the liquid and solid, and use the red mud filter cake for later use. Take 10g of red mud filter cake, wash at 95°C and dry at 120°C, analyze its composition (wt%), the results show that Al in red mud 2 o 3 The content is 6...

Embodiment 3

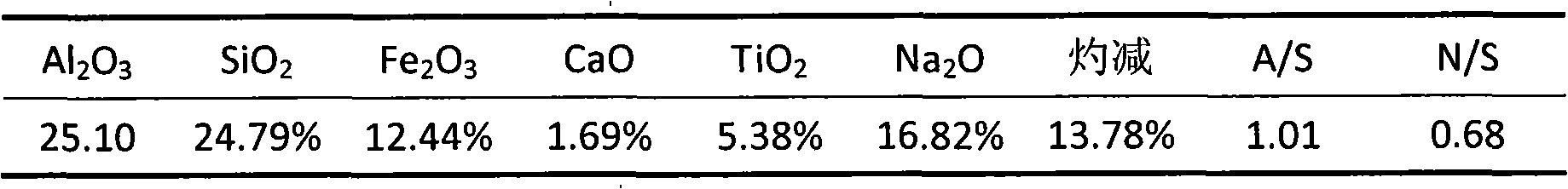

[0031] Using low-temperature and low-pressure hydrochemical method to recover alumina and sodium oxide from high-alkali red mud obtained by dissolving medium and low-grade bauxite with less calcium oxide as raw material. The raw material red mud composition (wt%) is as follows:

[0032]

[0033] The specific processing steps are as follows:

[0034] 1. Take a certain amount of red mud and milk of lime and add it to the NaOH solution with a mass percentage concentration of 45%. The amount of milk of lime added is based on CaO and SiO in the red mud. 2 The molar ratio of NaOH and red mud is calculated as 1:1, and the mass ratio of NaOH to red mud is 4:1. After mixing evenly, transfer it to the reactor, adjust the stirring speed, set the temperature control program, and raise the temperature of the reactor to 210°C for 3.5 h, and then turn on the cooling water to end the reaction; filter the reaction slurry while it is hot, separate the liquid from the solid, and use the red ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com