Real-time monitoring method of ice coated on overhead transmission line conductor and system

A technology of overhead transmission line and real-time monitoring system, which is applied in the fields of monitoring and prevention, early warning of icing on transmission lines, and monitoring of transmission line conductors. It can solve problems such as low temperature, camera failure, and low labor efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

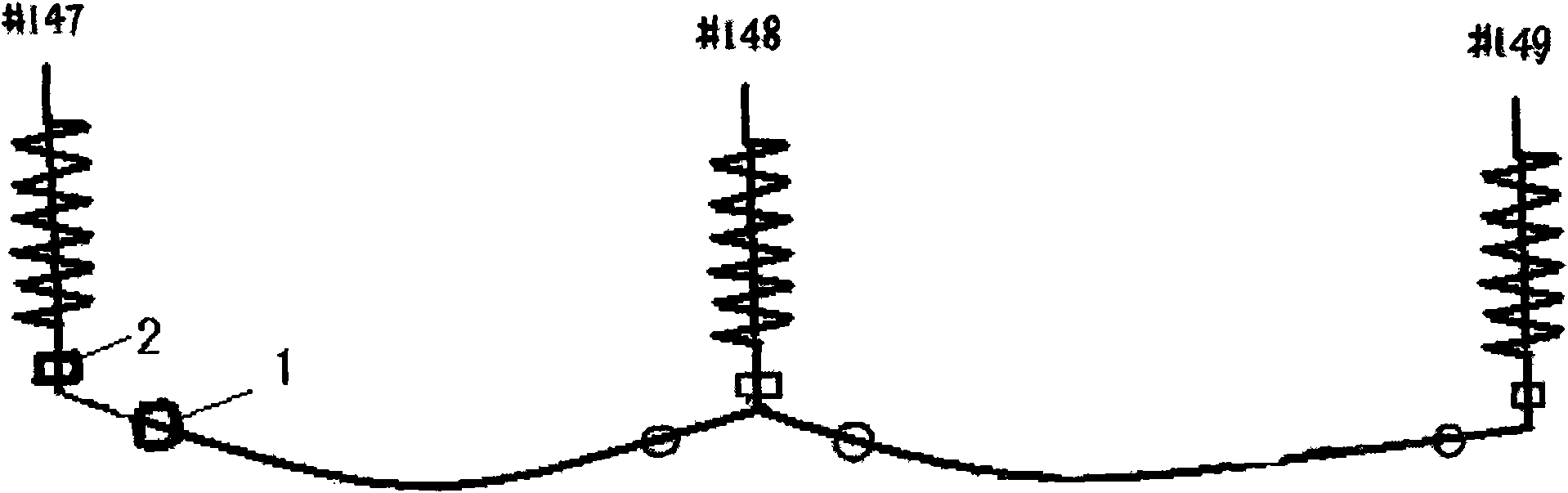

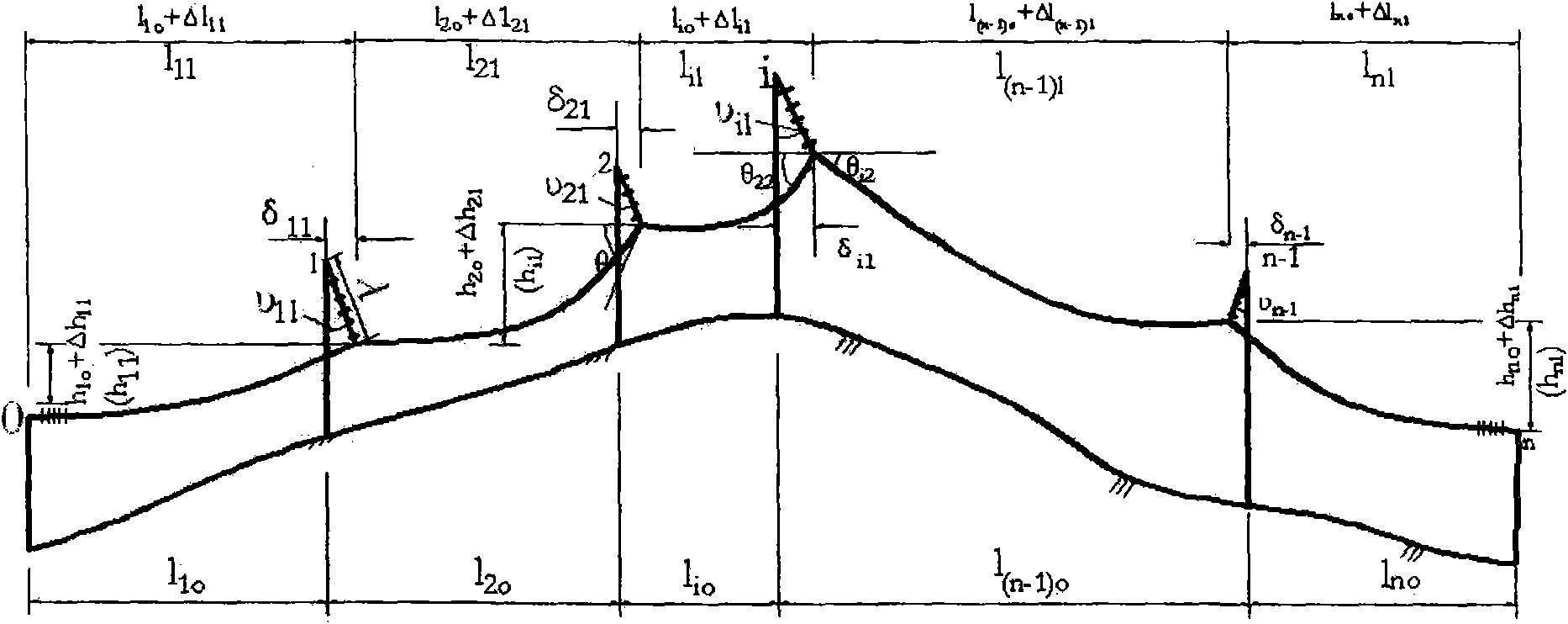

[0036] Example 1: Taking a tensile section of an ice-coated conductor of a 500kV line as an example, the 4th gear (#147-#148) and the 5th gear (#148-#149) in it, the wire model is 4*LGJ-630 / 45, the span of the fourth gear is 352m, the height difference is 39.0m, and the installation sag is 9.27m; the span of the fifth gear is 437m, the height difference is 1.0m, and the installation sag is 14.20m. The temperature is 0°C and the horizontal tension is 33950N. The length of the suspension insulator string is 5.5m and the weight is 1960N.

[0037] The basic parameters of the wire are: calculated section 666.55mm 2 ; Outer diameter 33.60mm; Unit mass 2.06kg / m; Elastic coefficient 63000N / mm 2 ; Linear expansion coefficient 20.9x10-61 / ℃.

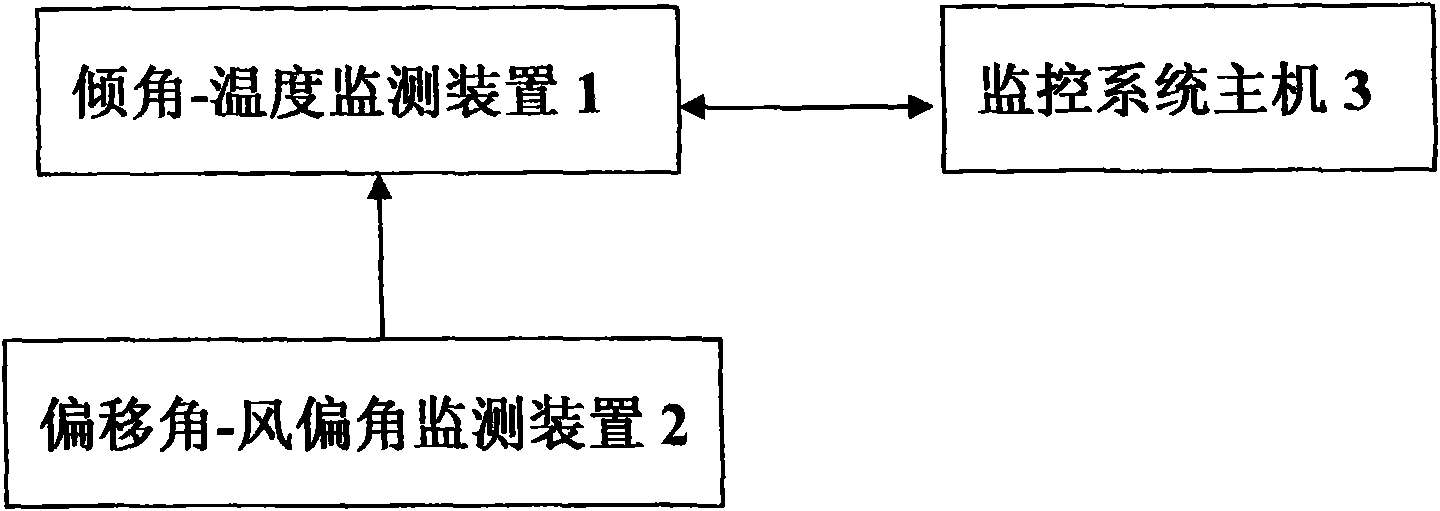

[0038] The real-time monitoring system for icing on overhead transmission line conductors includes a dip angle-temperature monitoring device 1, an offset angle-winding angle monitoring device 2, and a monitoring system host 3; the dip angle-tem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com