Self-calibrating method and apparatus for ultra precise workbench

A workbench and self-calibration technology, applied to measuring devices, complex mathematical operations, instruments, etc., can solve the problems of difficult calibration of three-dimensional ultra-precision workbench, poor scalability, limited application, etc., so as to avoid modeling errors and use flexibly , low-cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be described in detail below in conjunction with the accompanying drawings.

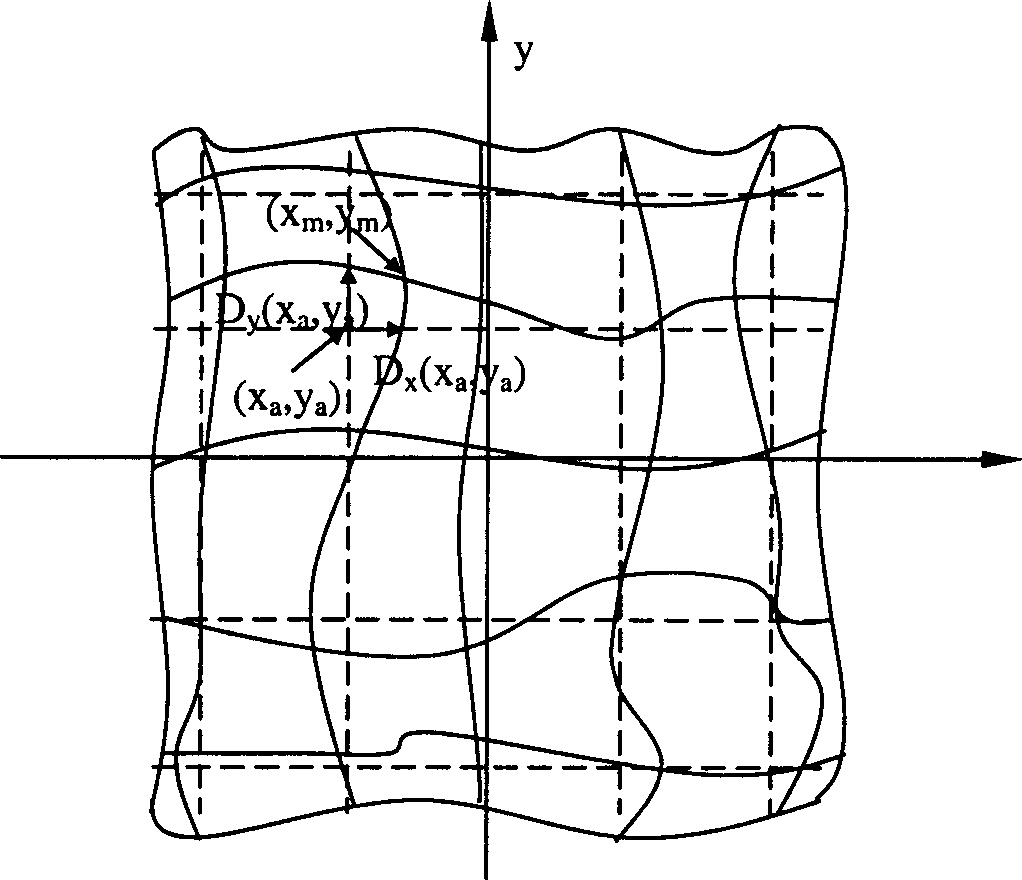

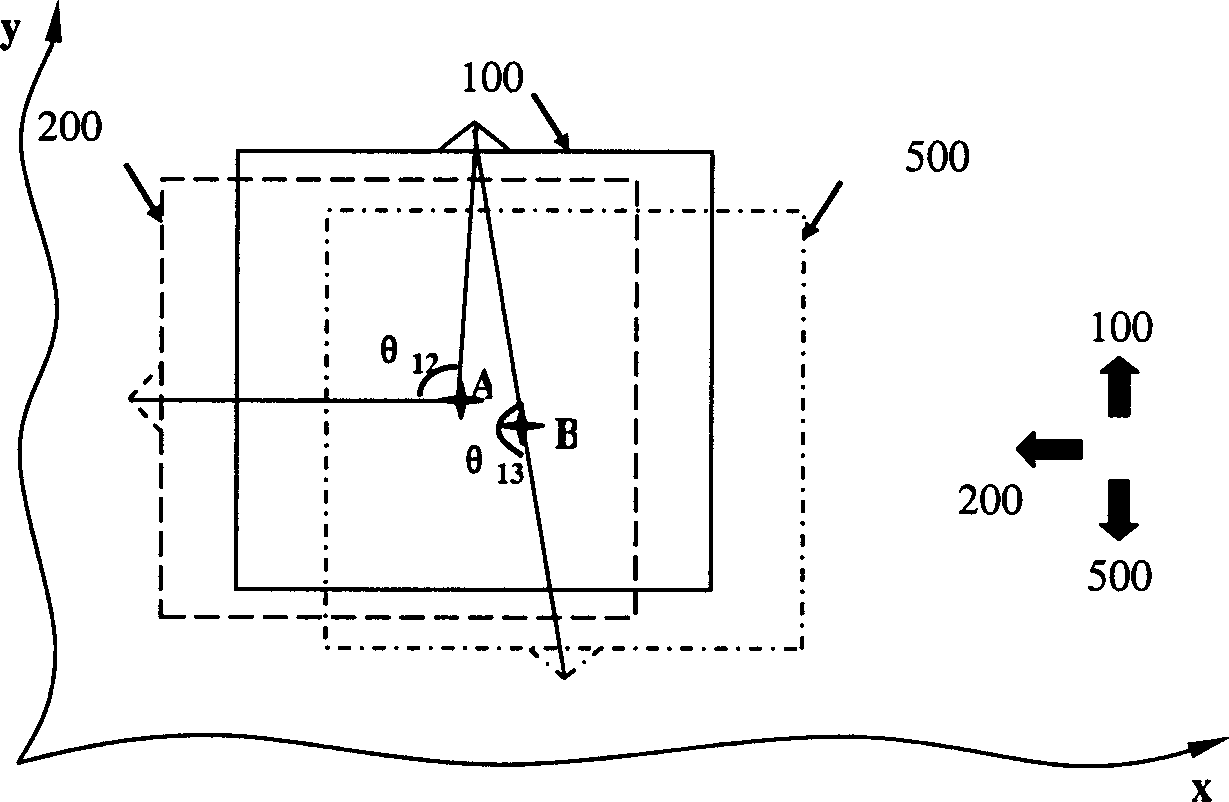

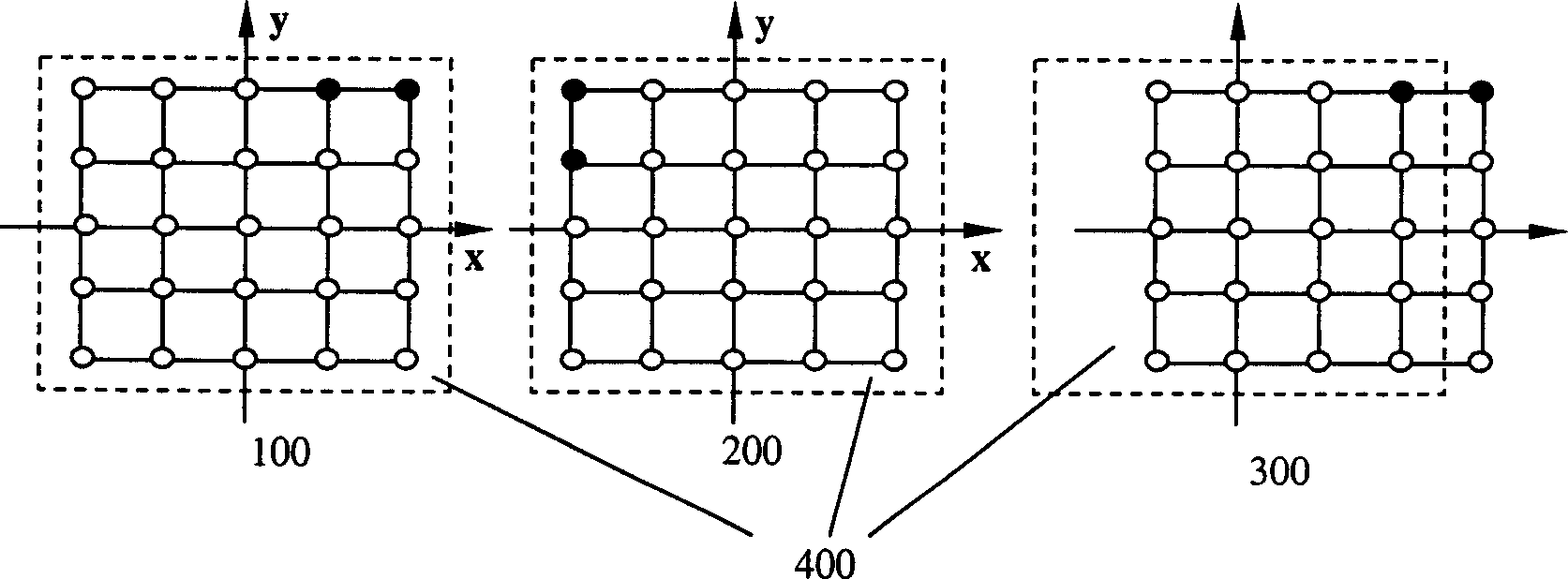

[0033] Such as Figure 6 As shown, the ultra-precision workbench self-calibration device described in the present invention includes an auxiliary measuring device 3 placed on the calibrated workbench 2, a positioning device placed above the auxiliary measuring device 3, and used for image acquisition and preview. An image acquisition card for processing and a computer 8 storing programs related to the self-calibration algorithm of the ultra-precision workbench. The auxiliary measurement device 3 adopts a chrome-plated grid glass plate with a grid mark matrix, which has a simple structure, strong processing technology, and is convenient to adjust between different measurement positions, and has excellent operability.

[0034] The positioning device includes an optical assembly 6 for enlarging the grid on the chrome-plated grid glass plate and an XY plane positioning ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com