Full-automatic weighing and packaging system and control method thereof

A packaging system, fully automatic technology, applied in the direction of packaging automatic control, packaging, packaging protection, etc., can solve the problems of high labor intensity, large dust, environmental pollution, etc., to reduce labor and labor intensity, improve work efficiency, and reduce dust. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

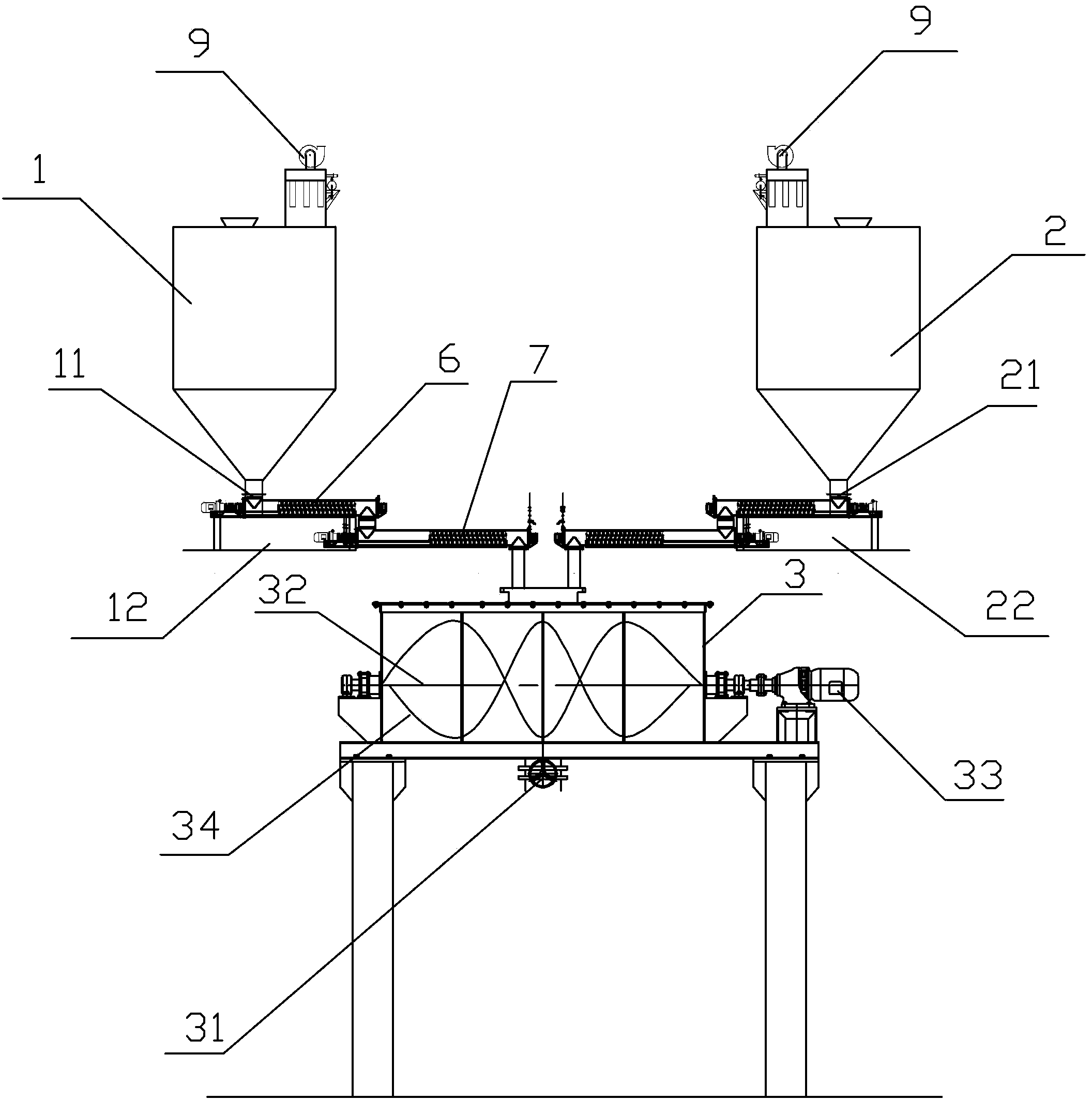

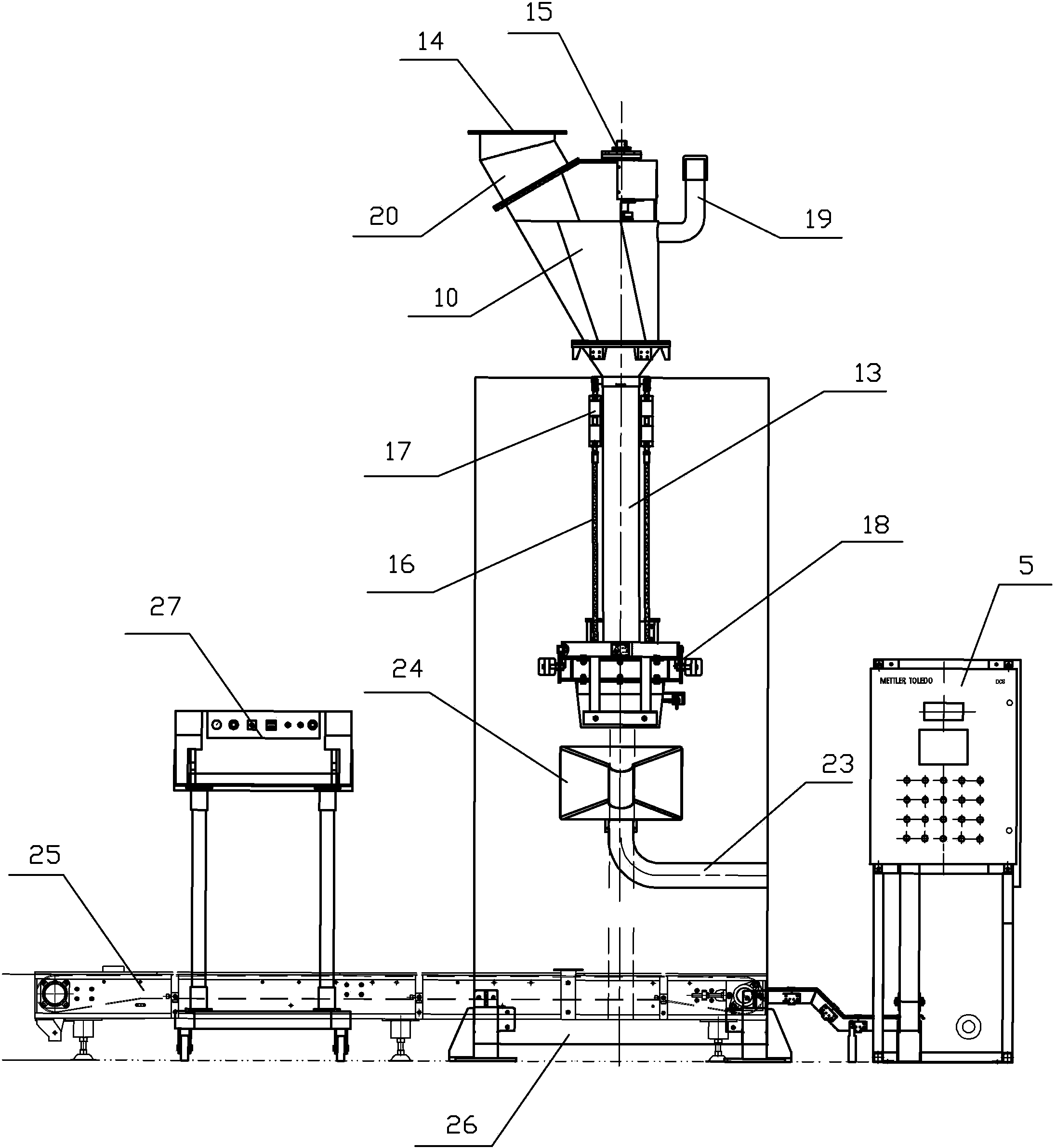

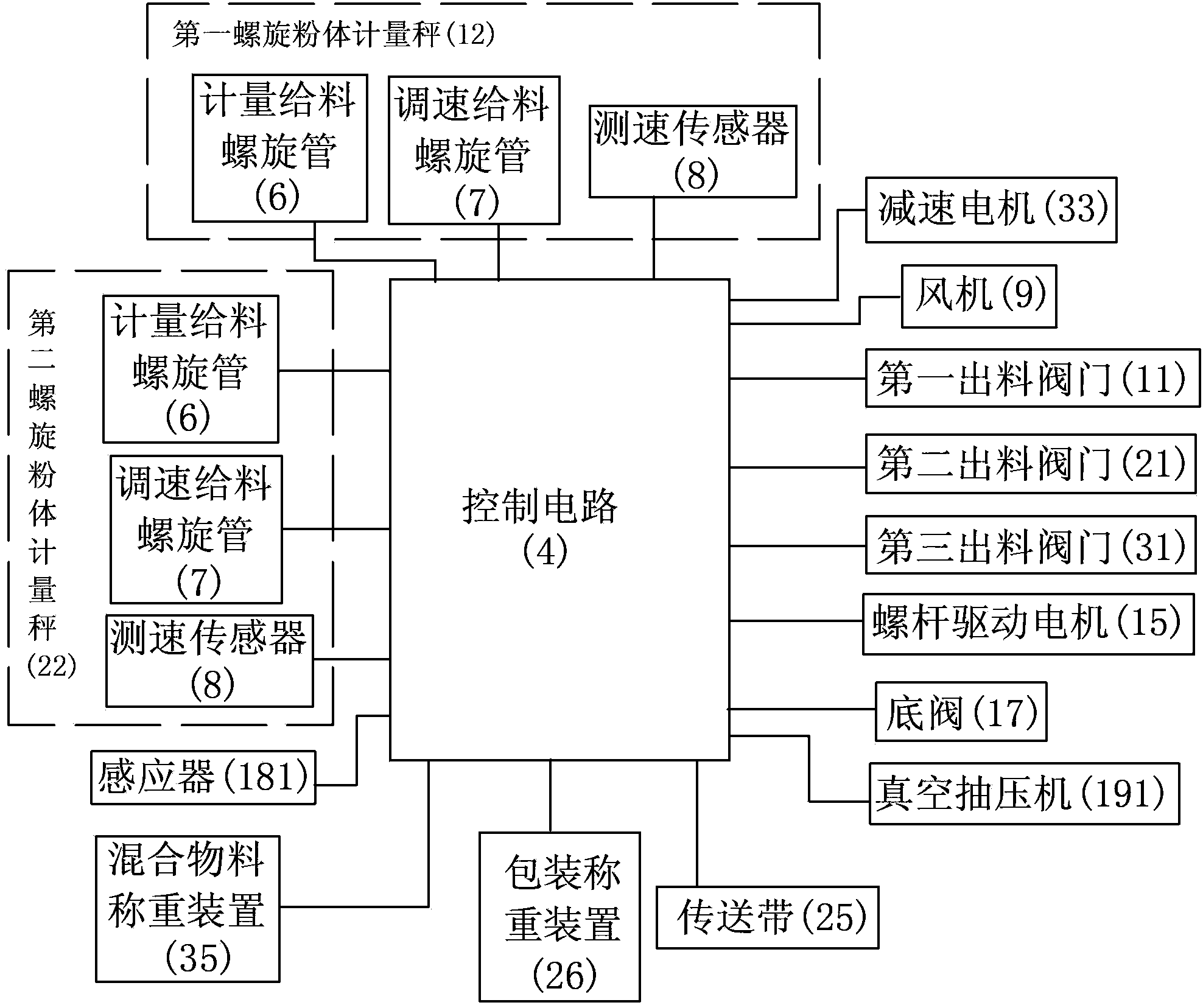

[0025] Embodiment: the fully automatic weighing and packaging system of this embodiment, such as figure 1 As shown, it includes a first material tank 1, a second material tank 2, a first screw powder weighing scale 12, a second screw powder weighing scale 22, a mixing bin 3, a packaging mechanism and a control cabinet equipped with a control circuit 4 5. The first discharge valve 11, the second discharge valve 21 and the third discharge valve 31 are respectively installed on the bottom of the first material tank 1, the second material tank 2 and the mixing silo 3, the first material tank, the second material The top of the tank respectively has a feeding port, and a fan 9 for air extraction is also installed on the top side. The first and second spiral powder weighing scales 12 and 22 all include a connected metering feeding spiral tube 6 and a speed-regulating feeding screw tube 7, and the two metering feeding spiral tubes are connected to the first discharge valve and the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com