Method and system for analyzing steam suction condition of thick oil horizontal well

A horizontal well and condition technology, applied in the field of petroleum exploration, can solve the problems of ineffective evaluation of horizontal well reservoir production status, irrationality, and too simple evaluation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

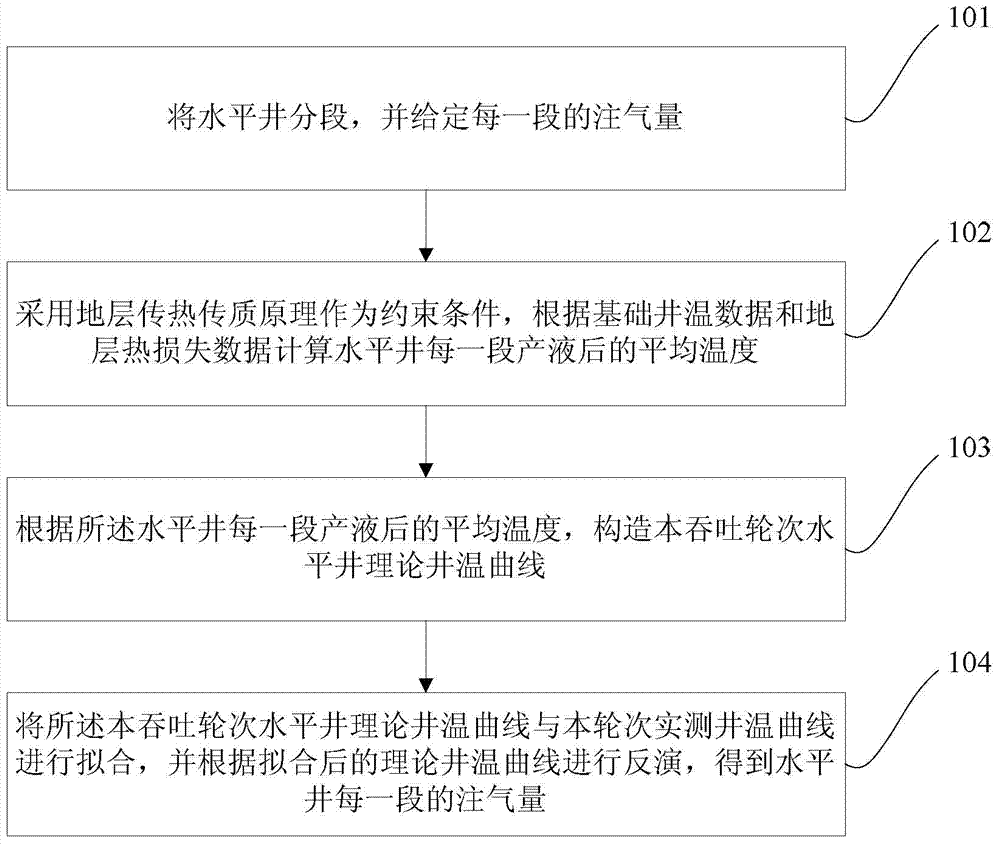

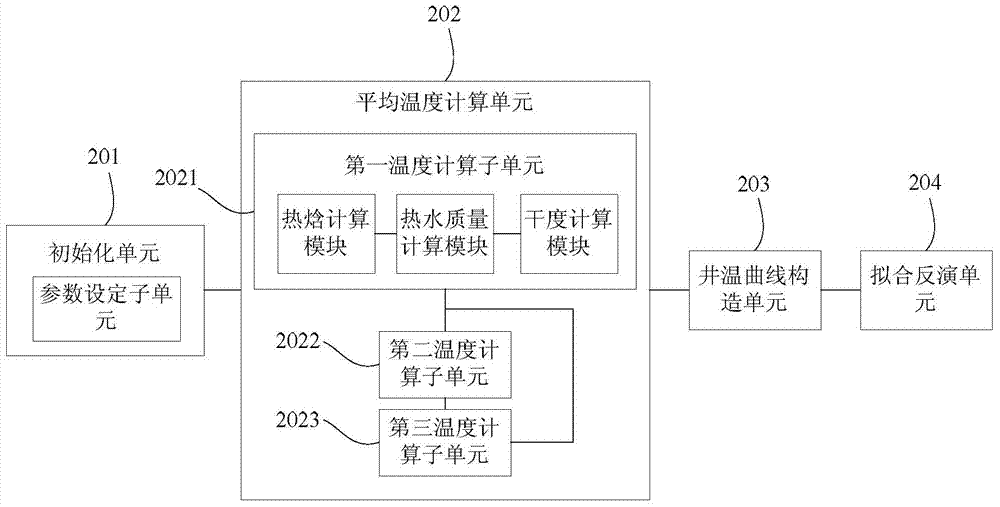

[0087] Such as figure 1 As shown, it is a flow chart of a method for analyzing the steam absorption status of a heavy oil horizontal well in this embodiment, including the following steps:

[0088] Step 101, segmenting the horizontal well, and specifying the gas injection rate for each segment;

[0089] Step 102, using the formation heat and mass transfer principle as a constraint condition, calculating the average temperature of each section of the horizontal well after liquid production according to the basic well temperature data and formation heat loss data;

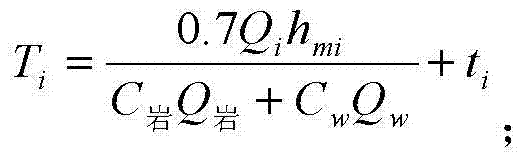

[0090] Before the steam dryness is not zero, the average temperature of each section of the horizontal well after simmering is:

[0091]

[0092] Among them, 0.7 is the thermal efficiency of the oil layer; C w is the specific heat of saturated water; C 岩 is the specific heat of rock; Q i is the suction volume of each section of the horizontal well; Q 岩 is the mass of hot water in the rock; Q w is the mass of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com