Automatic drilling equipment for sheet metal

A technology of drilling equipment and sheet metal, which is applied in the direction of drilling/drilling equipment, boring/drilling, metal processing equipment, etc., can solve the problems of low efficiency, poor hole quality, high cost, etc., and achieve high efficiency, Low processing cost and good hole quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

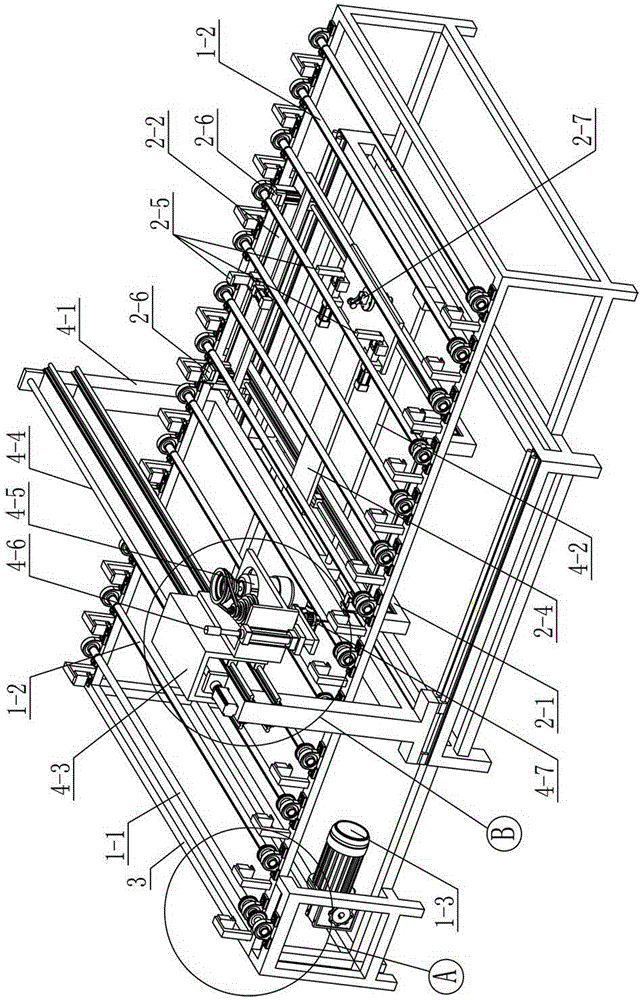

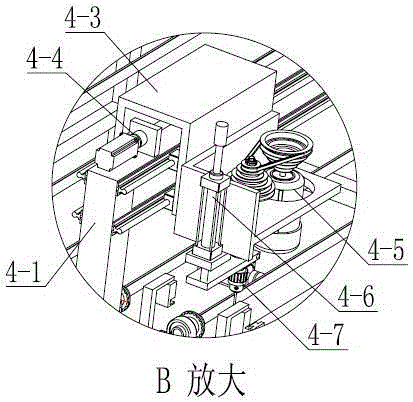

[0026] Referring to the accompanying drawings, an automatic sheet metal drilling equipment includes: an automatic control part, a frame part, a sheet material conveying part, a sheet material positioning and holding part and an automatic drilling part.

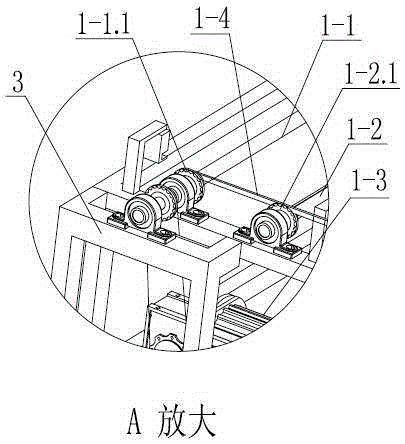

[0027] ⑴. The sheet conveying part includes: an active conveying roller 1-1, a group of passive conveying rollers 1-2 arranged in parallel, a conveying motor 1-3 and a transmission belt 1-4.

[0028] The conveying motor 1-3, the active conveying roller 1-1, and the passive conveying roller 1-2 are installed on the frame part 3 respectively, and the conveying motor 1-3 forms a transmission connection with the active conveying roller 1-1 through a transmission mechanism. , the driving belt pulley 1-1.1 on the driving conveying roller 1-1 forms a transmission connection with the passive belt pulley 1-2.1 on the passive conveying roller 1-2 through the transmission belt 1-4.

[0029] During use, the transmission motor 1-3 drives t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com