Backpitch shattering and dust collecting drill bit

An anti-spiral and drill bit technology, used in drill bits, drilling equipment, earth-moving drilling, etc., can solve the problems of gas and coal dust explosion, danger to operators, easy accidents, etc., to achieve efficient gas transmission, reduce maintenance costs, and be difficult to The effect of blocking the channel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

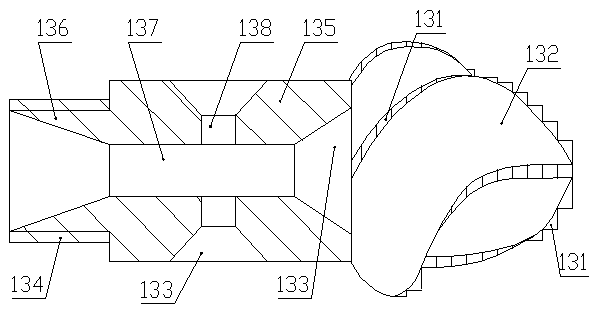

[0012] In the present invention, the direction of drilling with the drill bit is forward.

[0013] Such as figure 1 As shown, the anti-helical crushing and dust-absorbing drill bit of the present invention includes a connecting rod 135 and more than three (preferably in the range of 3-6) evenly arranged anti-helical blades 132, and the edges of each anti-helical blade 132 are provided with Blade 131; the rear end of each anti-helical blade 132 is connected to the front end of the connecting rod 135, and the rear diameter of the connecting rod 135 is smaller than the main body diameter of the connecting rod 135 and forms a coupling portion 136 for connecting the drill rod. The circumferential surface of the portion 136 is provided with coupling threads 134 .

[0014] The connecting rod 135 is provided with an axial air channel 137 passing through the connecting rod 135 at the axial position, and the front and rear ends of the axial air channel 137 are provided with bell mouths...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com