Compound tool applicable to high-speed and accurate holing on aircraft panel

A technology for aircraft siding and composite cutters, which is applied in the direction of manufacturing tools, drilling accessories, drilling/drilling equipment, etc., can solve the problems of increasing the amount of cutting tools, low efficiency, and reducing efficiency, so as to improve the accuracy of the hole surface and improve Economic benefits, the effect of reducing the amount of tools

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

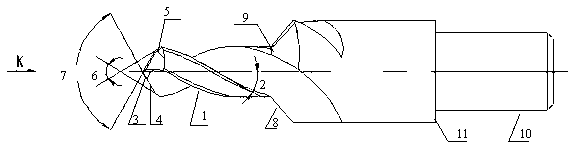

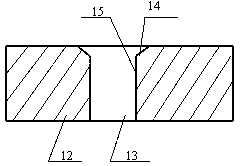

[0015] figure 1 Shown is the structure of the fastener hole 13 in the workpiece 12, consisting of a hole wall 15 and a conical socket 14 at the top of the hole. like image 3 As shown, after the compound tool drills a through hole on the workpiece 12, it continues to feed, and the countersink 8 of the compound tool is used to process the conical dimple 14, and the transition fillet between the hole wall 15 and the conical dimple 14 is also processed. When the tool needs to be replaced with a new tool due to damage, the position of the countersink 8 can be determined by using the end face 17 of the tool handle 16 to locate the step positioning surface 11, thereby ensuring the depth 18 of the taper pocket.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com