Construction method of static pressure compaction pile

A construction method and technology for compacting piles, applied in sheet pile walls, soil protection, infrastructure engineering and other directions, can solve problems such as normal construction, poor construction safety, environmental pollution, etc., to achieve good social and economic benefits, construction Stable quality, safe and reliable construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

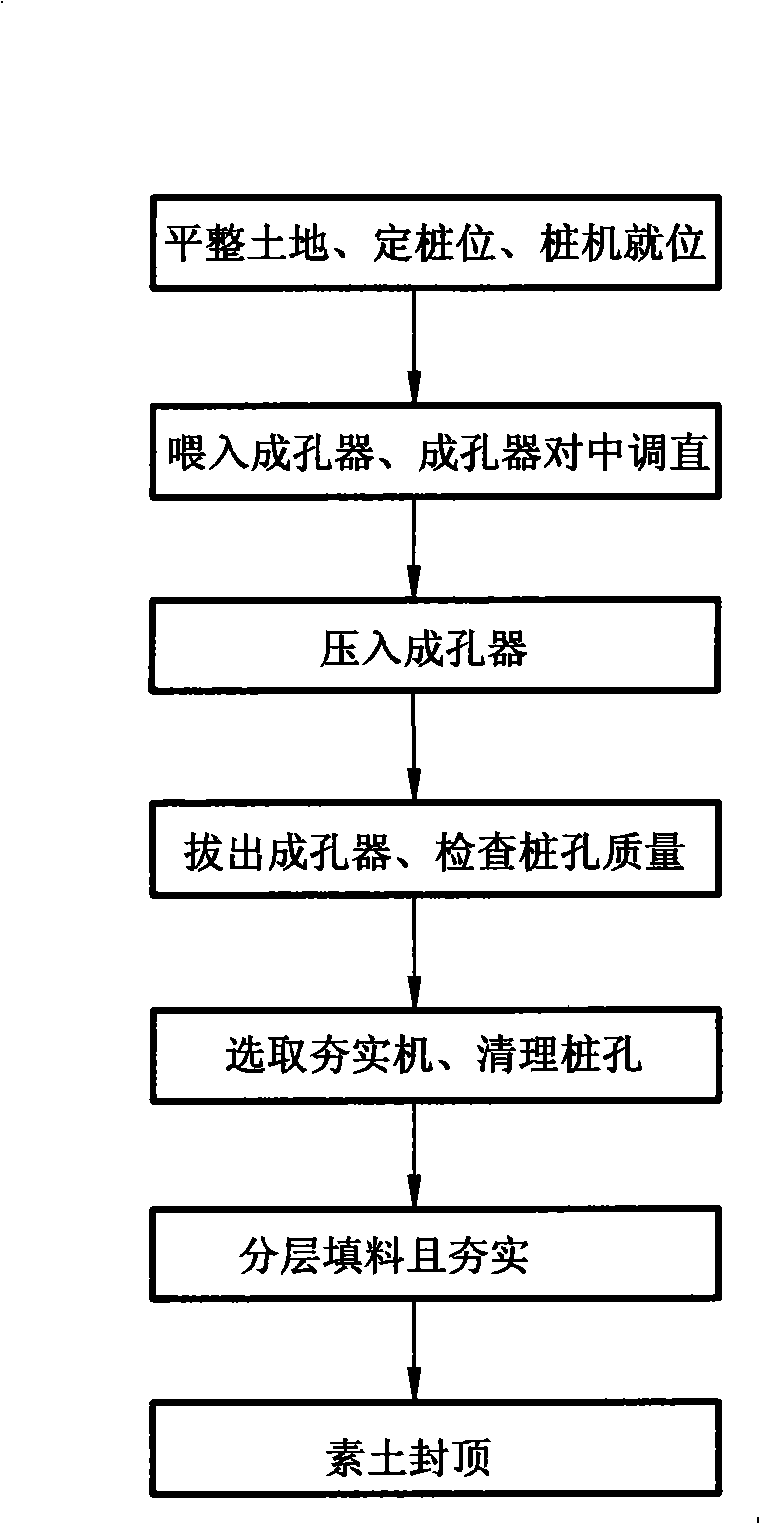

[0038] Embodiment one: see figure 1 , in the foundation treatment of a construction site, the construction method of static pressure compaction piles is adopted, which includes the following steps:

[0039] 1. Hole forming

[0040] (1) Leveling the site Before construction, remove all obstacles on the ground, compact the soft areas that are not conducive to mechanical operation, and level the site to meet the construction requirements of mechanical operations. Before pressing into the hole former, you should have a clear understanding of the soil layer and geological conditions at the site. At the same time, you should do a good job of inspection of the equipment to prevent accidents during the pile pressing process that will cause the pile to be interrupted, causing excessive resistance of the pile after the interval, and the occurrence of compaction. Accidents that don't go down.

[0041] (2) Positioning and measurement

[0042] According to the design of the pile positio...

Embodiment 2

[0068] Embodiment 2: This embodiment is basically the same as Embodiment 1, and the similarities will not be repeated. The difference is that the hydraulic static pile driver is a top-pressure hydraulic static pile driver, and the hole forming device is pulled out by a crane. out.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com