Funicular curve well drilling rail design method using stratum natural deflecting rule

A design method and catenary technology, applied in directional drilling and other directions, can solve the problems of not considering the natural deflection law of the formation, unfavorable for wellbore trajectory control, and unable to give the size of the azimuth advance angle.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

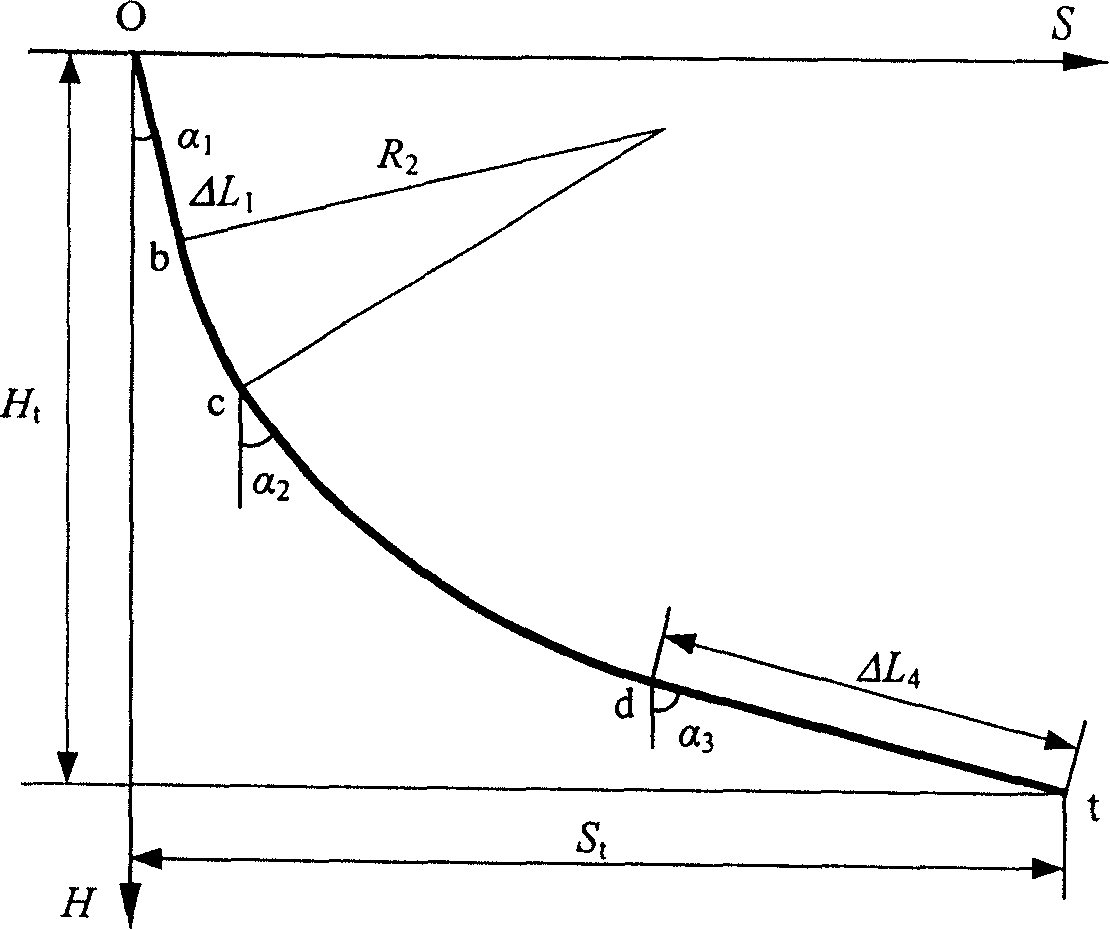

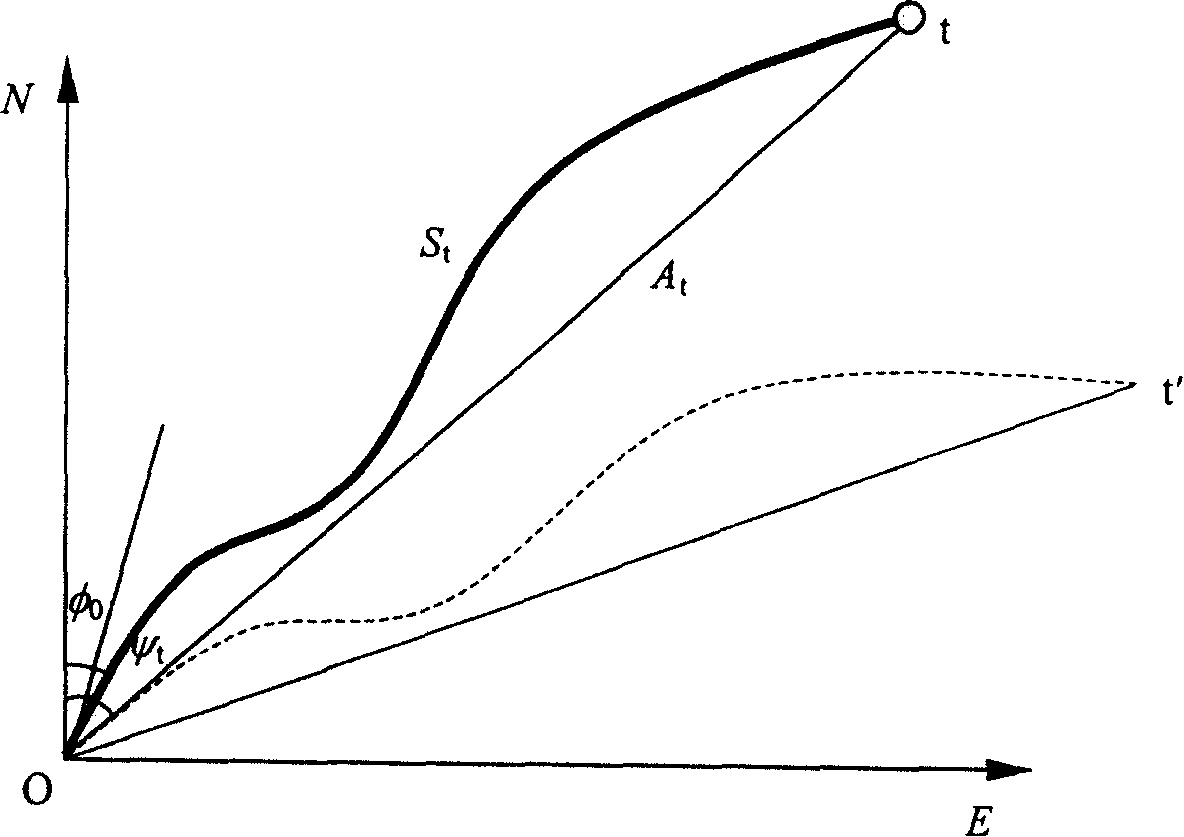

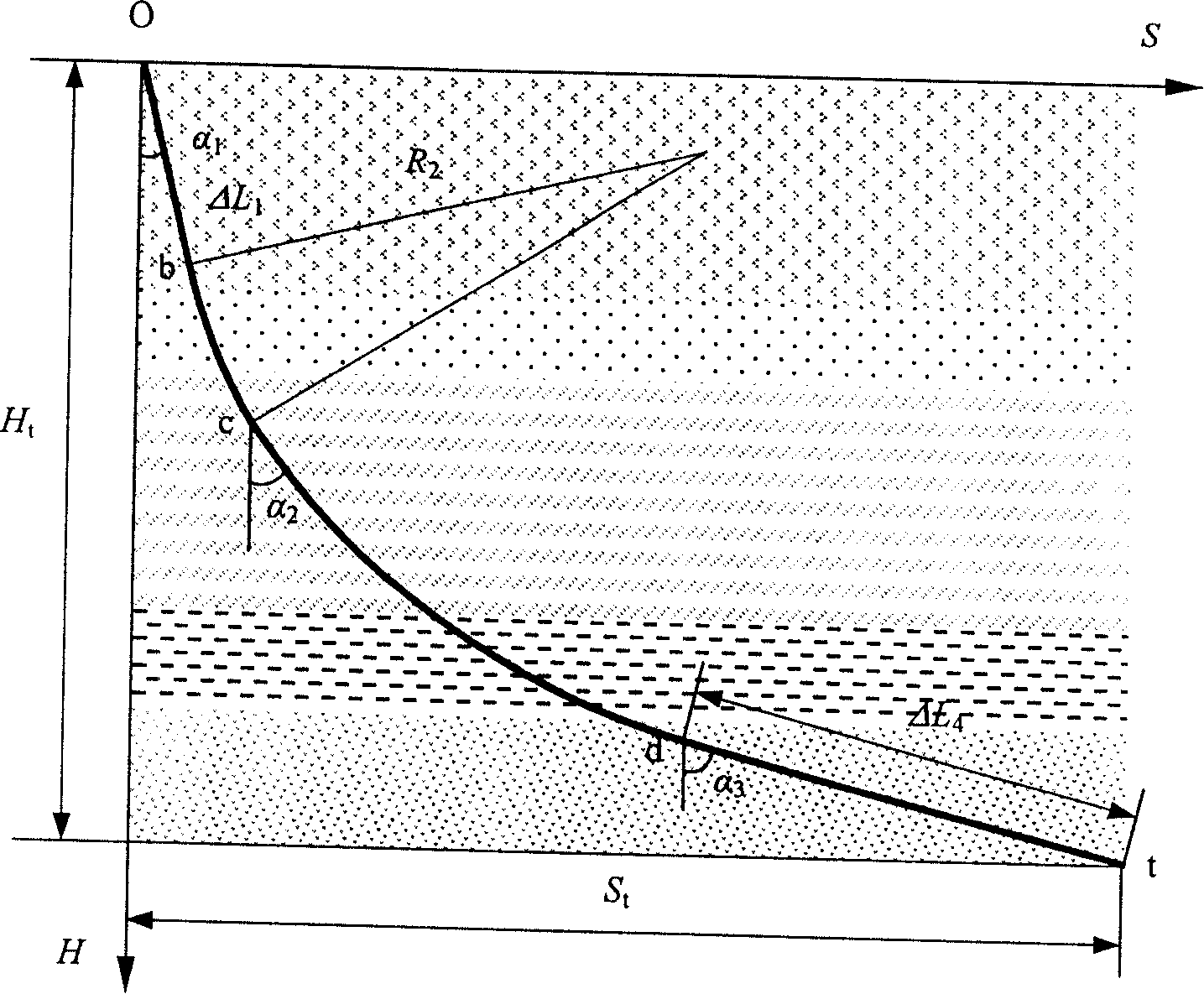

[0147] Target vertical depth H of an extended-reach well t =2800m, horizontal displacement A t =6000m, kickoff point depth ΔL 1 =300m, and above the kickoff point is the vertical well section, namely α 1 = 0°. Such as figure 1 As shown in the figure, ob segment is the stabilizing segment, bc segment is the arc segment, cd segment is the catenary segment, and dt segment is the stabilizing segment.

[0148] If the build-up slope of the arc transition section is κ 2 =10° / 30m, the initial inclination angle and the end inclination angle of the stabilizing section are α 2 = 42° and α 4 =78°, the wellbore trajectory is designed by adopting the catenary wellbore section.

[0149] According to the computing method of the present invention, get: during two-dimensional design,

[0150] The characteristic parameter of the catenary well section is a=3569.85m,

[0151] Section length ΔL of stabilizing section 4 =3364.55m,

[0152] Segment length ΔL of catenary section 3 = 3205....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com