Technique for parallel processing drilling fluid and zero discharge of drill cuttings

A parallel processing and drilling fluid technology, applied in the field of comprehensive technology, can solve the problems of poor initiative, increasing the volume of waste drilling fluid, wasting drilling fluid, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

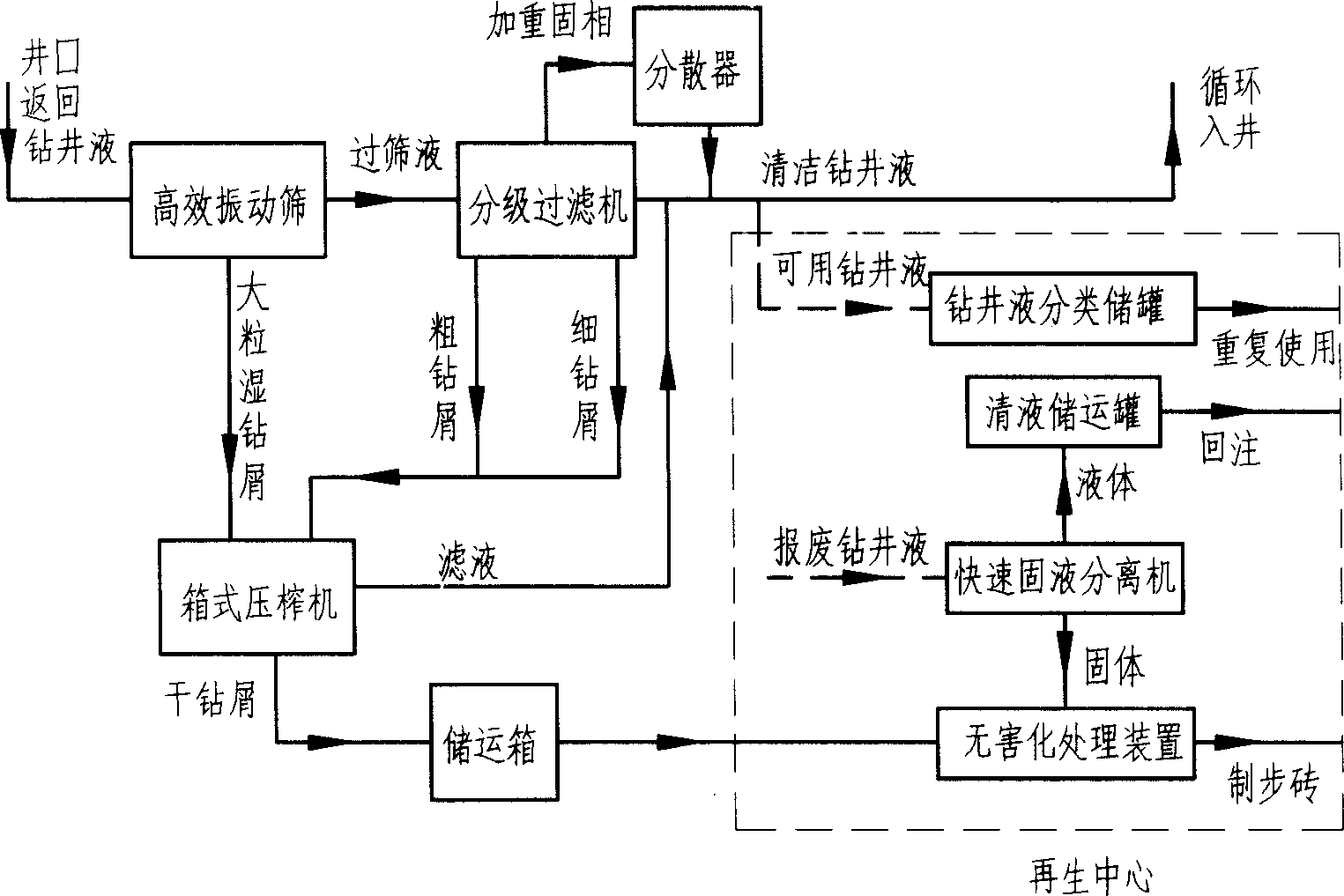

[0010] The zero-discharge parallel processing technology for drilling fluid and cuttings provided by the invention will be specifically described below in conjunction with the accompanying drawings.

[0011] As shown in the drawings, the drilling fluid solid phase control process flow of the present invention is: drilling fluid returning to the wellhead → high-efficiency vibrating screen → grading filter → cleaning drilling fluid → circulation into the well. The high-efficiency vibrating screen can use more than 200 mesh screens, which saves the huge energy-consuming desander and desilter, simplifies the original solid control process, and provides conditions for the work of the grading filter. The drilling fluid returned to the wellhead is divided into large wet cuttings (>74μm) and sieving fluid after being passed through a high-efficiency vibrating screen. 35 μm), aggravated solid phase (35 μm ~ 15 μm) and fine cuttings (2 μm ~ 15 μm), the aggravated solid phase re-enters t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com