Polymer drilling fluid with high temperature resistance

A technology of polymer and high temperature resistance, applied in the direction of drilling compositions, chemical instruments and methods, etc., can solve the problems of large amount of sulfonated treatment agent, heavy drilling fluid workload, environmental pollution, etc., to prevent mud bag sticking Drilling, good environmental protection, simple preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

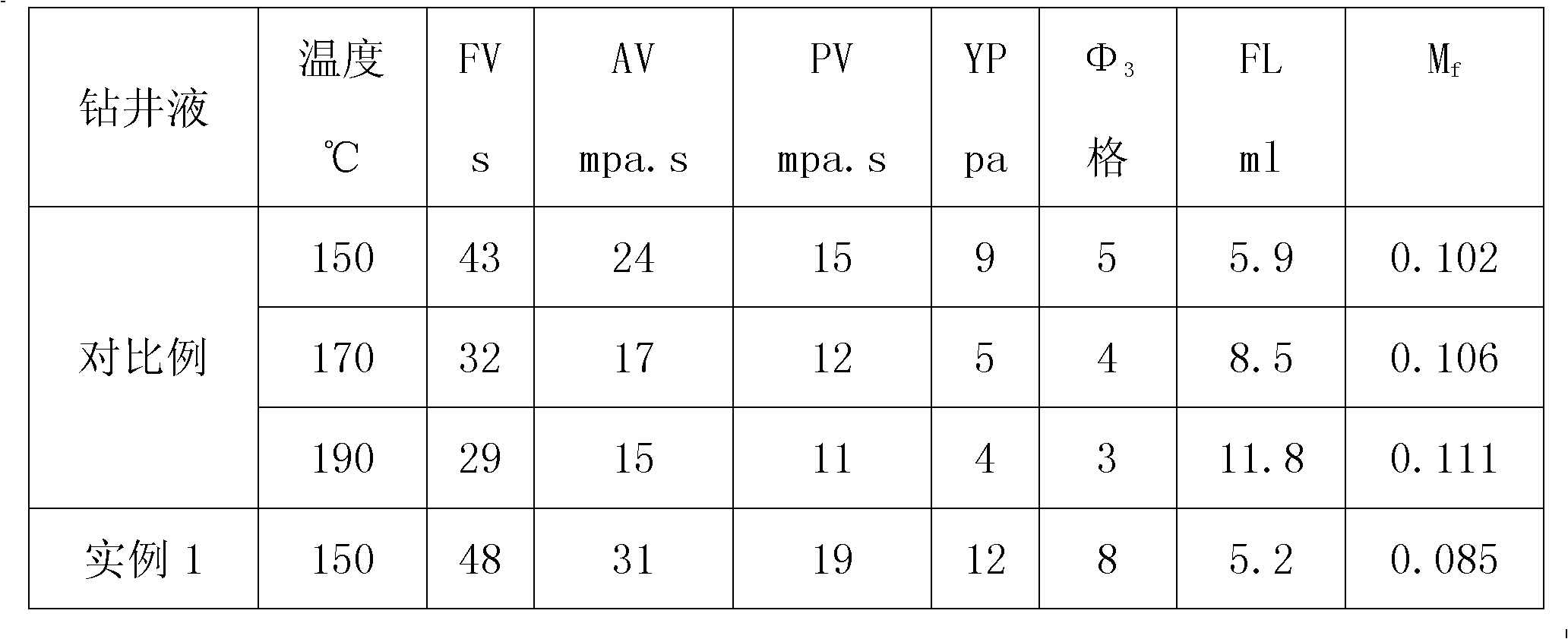

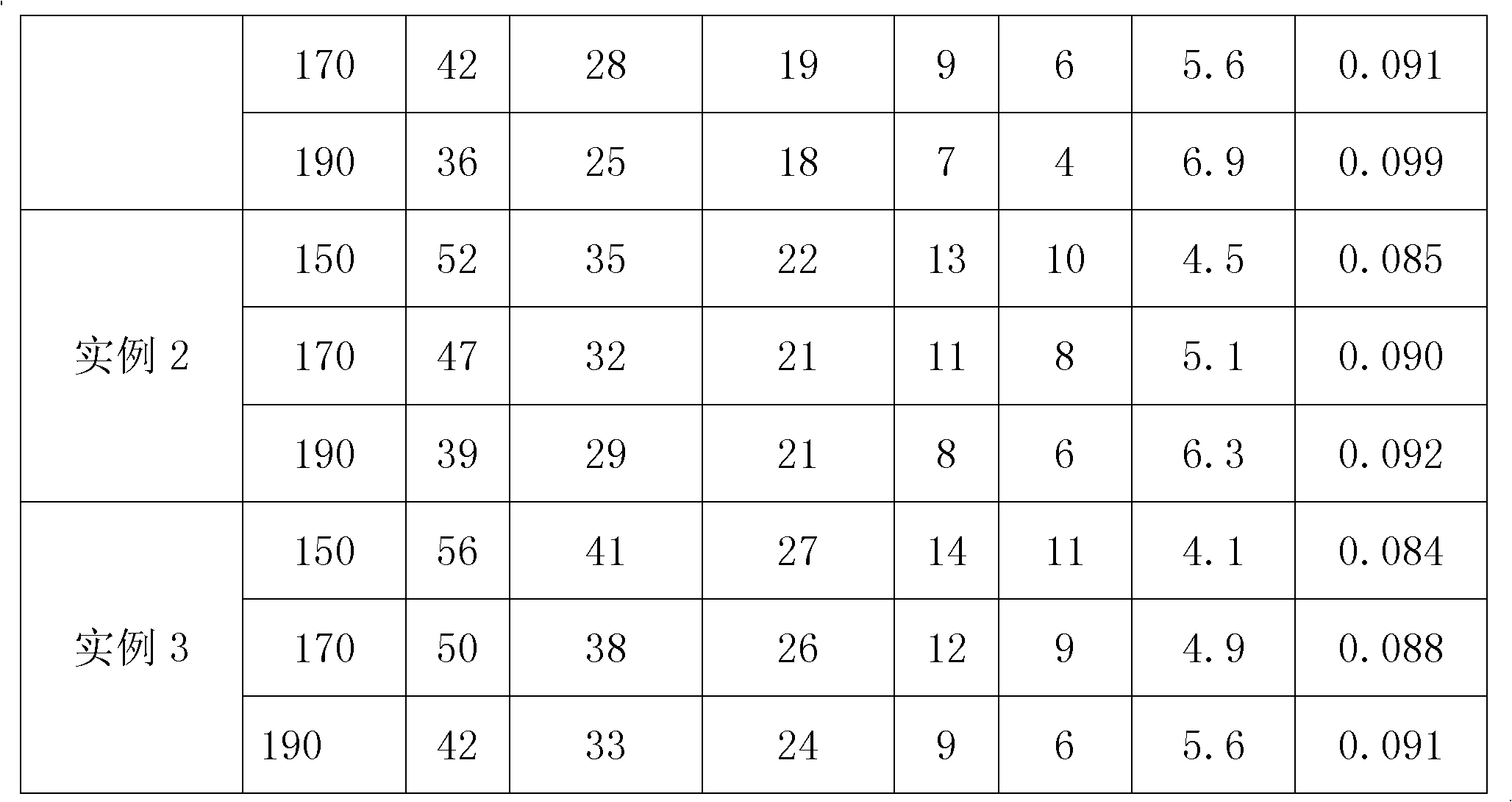

Embodiment 1

[0036] A kind of high temperature resistant polymer drilling fluid provided by the present invention, wherein the weight percent of each component is:

[0037] Bentonite: 4%; Polymer viscosifier (80A51): 0.3%; Inhibitor (KPAM): 0.4%; Anti-high temperature polymer fluid loss additive: 0.3%; Anti-high temperature sulfonated fluid loss additive: 3% Lubricant (emulsified asphalt): 3%; Temperature stabilizer: 0.4%; Sodium carbonate: 0.15%; Sodium hydroxide: 0.1%; / cm 3 .

Embodiment 2

[0039] A kind of high temperature resistant polymer drilling fluid provided by the present invention, wherein the weight percent of each component is:

[0040] Bentonite: 4%; Polymer viscosifier (80A51): 0.3%; Inhibitor (KPAM): 0.4%; Anti-high temperature polymer fluid loss additive: 0.4%; Anti-high temperature sulfonated fluid loss additive: 3% Lubricant (emulsified asphalt): 3%; Temperature stabilizer: 0.4%; Sodium carbonate: 0.15%; Sodium hydroxide: 0.1%; / cm 3 .

Embodiment 3

[0042] A kind of high temperature resistant polymer drilling fluid provided by the present invention, wherein the weight percent of each component is:

[0043] Bentonite: 4%; Polymer viscosifier (80A51): 0.4%; Inhibitor (KPAM): 0.4%; Anti-high temperature polymer fluid loss additive: 0.5%; Anti-high temperature sulfonated fluid loss additive: 3% Lubricant (emulsified asphalt): 3%; Temperature stabilizer: 0.4%; Sodium carbonate: 0.15%; Sodium hydroxide: 0.1%; / cm 3 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com