Coal seam well wall stability analysis method under multi-factor coupled effect

An analysis method and stability technology, which are applied in the field of wellbore stability analysis and drilling mud density window calculation, can solve the problems that it is difficult to reflect the real situation of coal seam drilling wellbore stability, and the mud density is difficult to work.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

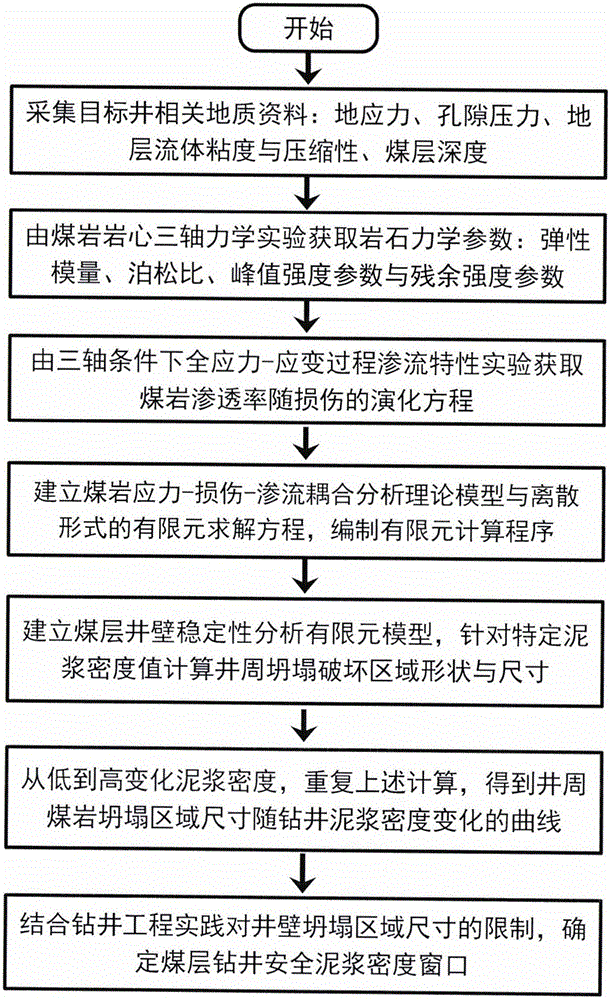

[0037] A coal seam well wall stability analysis method under the coupling effect of multiple factors proposed by the present invention is described as follows in conjunction with the accompanying drawings, taking the well wall stability analysis of a coal bed methane well as an example.

[0038] According to attached figure 1 As shown, the first to third steps of the method proposed by the present invention are to collect relevant geological data of the target well and conduct indoor experiments on cores to obtain relevant physical and mechanical properties of the target coal seam. This example considers a vertical well in Qinshui Basin, Shanxi, the target reservoir depth is 717.5m, the drill bit size is 219.5mm, the elastic modulus of coal rock is 2.50GPa, Poisson’s ratio is 0.33, the peak cohesion and internal friction angle are respectively is 2.5MPa and 35.0°, the overburden pressure is 18.6MPa, the horizontal maximum and minimum principal stresses are 17.7MPa and 12.9MPa ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com