Shale gas exploitation oil-based drilling fluid well-cementing prepad fluid

A technology of oil-based drilling fluid and cementing pre-fluid, applied in drilling compositions, chemical instruments and methods, etc., can solve the problems affecting the quality of cementing, the performance of cementing slurry, and it is difficult to achieve flushing and isolation. , replacement and other problems to achieve the effect of improving cementing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] 1. Prepare cleaning solution: cleaning solution additive: 25%, weighting agent: 50%, water: 25%;

[0024] 2. Preparation of flushing liquid: flushing liquid additive: 6%; weighting agent: 40%, water: 54%;

[0025] 3. Preparation of spacer fluid: spacer fluid additive: 6%, weighting agent: 35%, water: 59%;

[0026] According to the pre-fluid 20m on site 3 design, where the cleaning fluid 10m 3 , accounting for 50% by volume; flushing solution 10m 3 , accounting for 50% of the volume; spacer 0m 3 , accounting for 0% by volume.

Embodiment 2

[0028] 1. Prepare cleaning solution: cleaning solution additive: 25%, weighting agent: 50%, water: 25%;

[0029] 2. Preparation of flushing liquid: flushing liquid additive: 6%; weighting agent: 40%, water: 54%;

[0030] 3. Preparation of spacer fluid: spacer fluid additive: 6%, weighting agent: 35%, water: 59%;

[0031] According to the pre-fluid 25m on site 3 design, where the cleaning fluid 10m 3 , accounting for 40% by volume; flushing solution 10m 3 , accounting for 40% by volume; spacer 5m 3 , accounting for 20% by volume.

[0032] The method of using the pre-fluid on site is: prepare the required cleaning solution in the 1# mixing tank, prepare the required rinsing solution in the 2# mixing tank, and prepare the required spacer solution in the 3# mixing tank; strictly follow the cleaning solution on site, The sequence and ratio of flushing fluid and spacer fluid are injected into the well to achieve the purpose of cleaning, displacement and isolation.

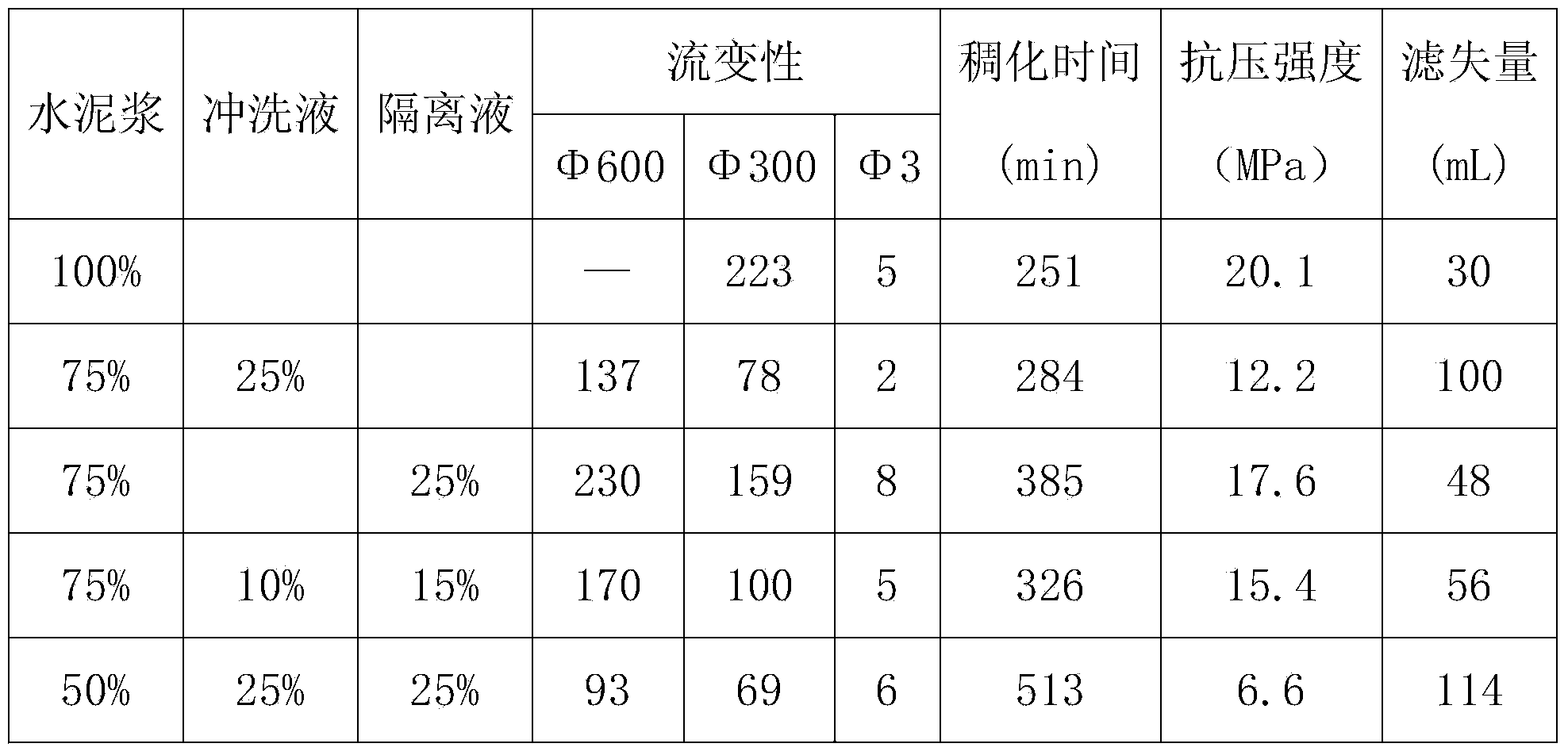

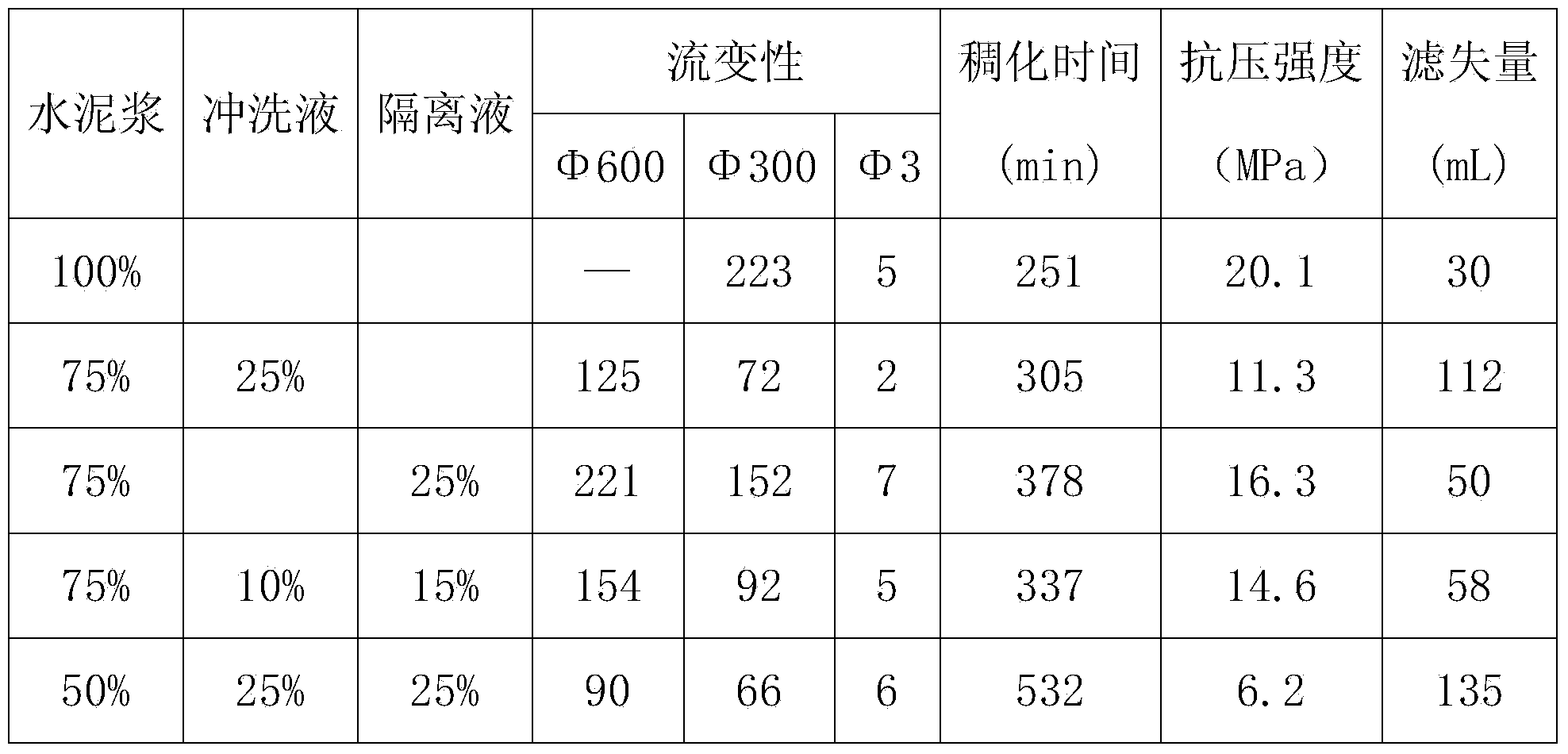

[0033] Tab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com