Drill bit with telescopic blades

A technology of telescopic knives and drill bits, which is used in drill bits, drilling equipment, earth-moving drilling, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

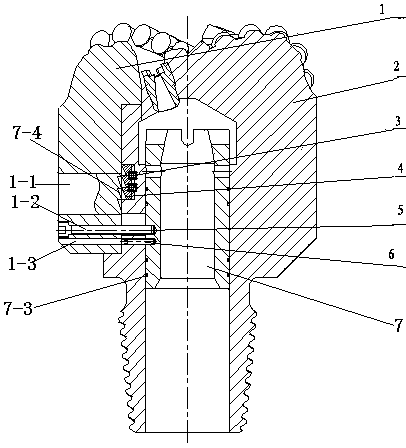

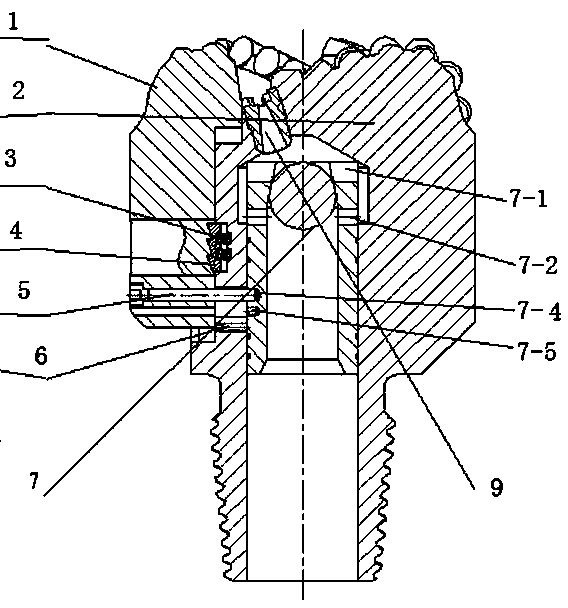

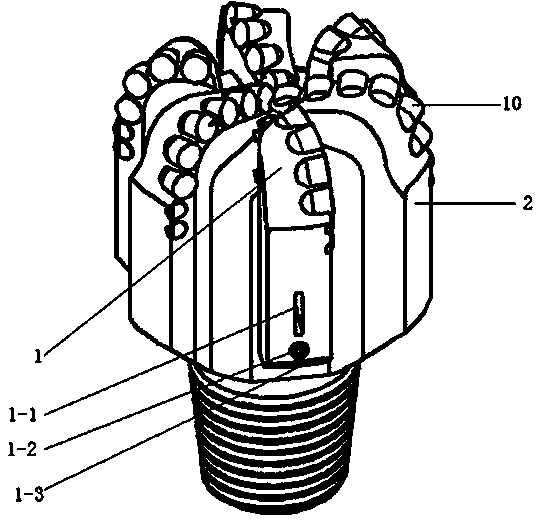

[0028] Embodiment 1, a PDC drill bit with a telescopic blade, including a drill body, a nozzle 9, a telescopic blade 1, a locking block 4, a ball seat cover 7, a blocking ball 8, a compression spring 3, a shear screw 6, Linkage bolt 5, cutting tooth 10.

[0029] The connection structure between the telescopic blade 1 and the drill bit body is as follows: firstly, the internal structure of the drill bit body is redesigned. Three fan-shaped grooves are axially opened on the drill body between the fixed blades 2. The cross-section of the fan-shaped grooves has a "T"-shaped structure. The middle of the bottom of each fan-shaped groove is provided with a locking block groove. Set lock block 4. A compression spring or a compression spring sheet 3 is arranged between the locking block 4 and the bottom of the groove of the locking block. Below the bottom of the fan-shaped groove close to the groove of the locking block (note: the upper and lower positions involved in the present inv...

Embodiment 2

[0033]In Embodiment 2, a radial through hole is provided on the telescopic blade 1 corresponding to the locking block 4, so that the locking block 4 can be squeezed through the radial through hole by a tool during the installation of the telescopic blade. It also includes a sealing ring 7-3 at the junction of the ball seat cover 7 and the cylindrical cavity in the drill bit body to increase its sealing performance.

Embodiment 3

[0034] Embodiment 3, the locking block 4 is a one-way sliding wedge-shaped groove, and the groove on the telescopic blade 1 matched with it is a one-way sliding wedge-shaped groove. Of course, the cooperation between the two can also adopt the plug-in locking cooperation form of the protrusion and the groove.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com