Hydraulic torque converter

A hydraulic torque converter and hydraulic clutch technology, which is applied in the fields of mine drilling, oil and gas drilling, drilling tools, geological exploration, and coalbed methane drilling. It can solve problems such as large frictional resistance, complex internal structure, and easy sticking. To achieve the effect of increasing service life, improving safety and reliability, and avoiding pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

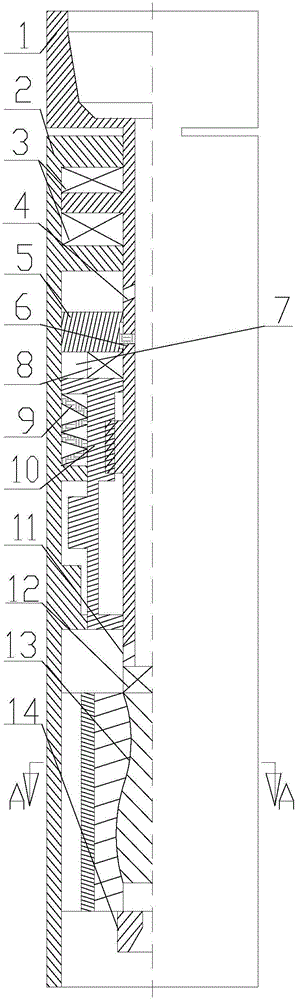

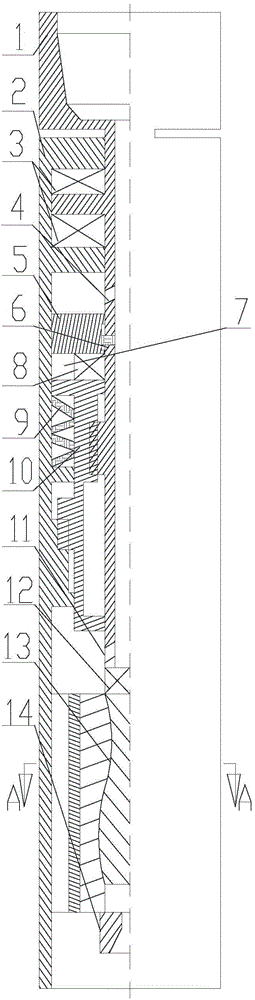

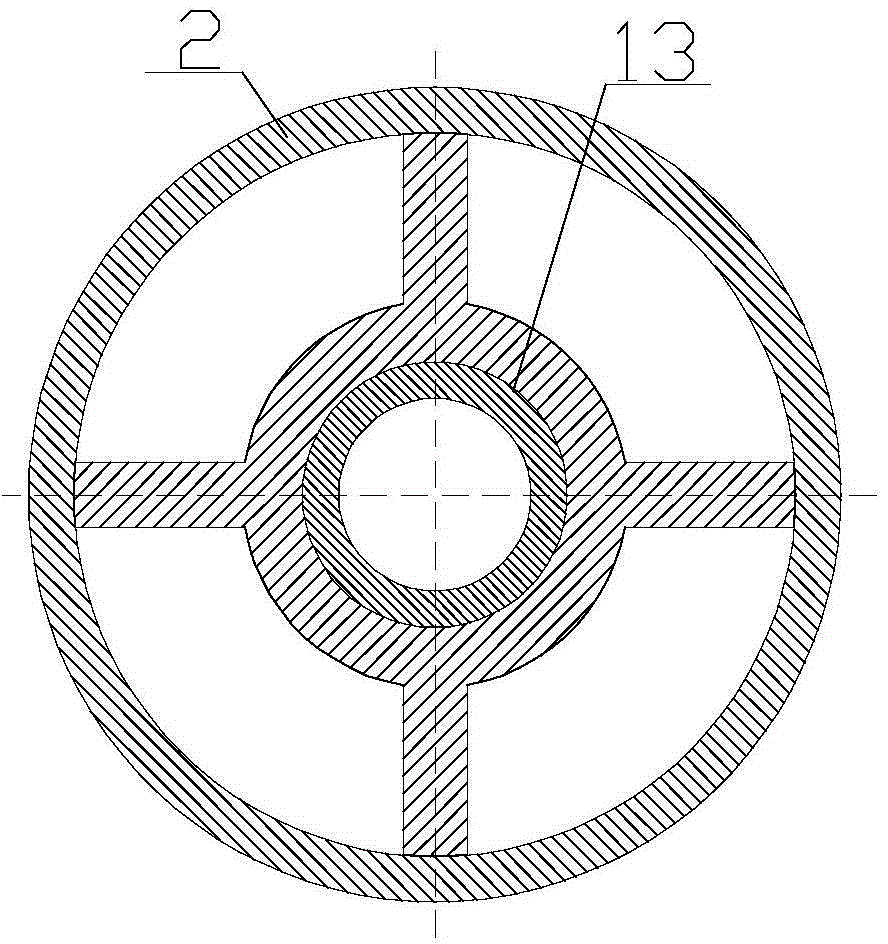

[0025] Refer to attached figure 1 with 2, The hydraulic torque converter includes a central shaft 1, an outer shell 2, bearing devices 3 and 8, a regulator 5, a spring 9, a hydraulic clutch 10, a coupling 12, a torque generator 13, and a nozzle 14. Wherein: the central shaft 1 does not have a connector, and the rest is installed inside the outer shell 2, and the central shaft 1 and the outer shell 2 form a rotating sealing fit through the bearing device 3 and the bearing convex edge. The adjuster 5 is installed in the annular cavity between the central shaft 1 and the outer shell 2, and forms a sealing fit with the central shaft 1 and the outer shell 2 in the axial direction. The positioning mechanism forms a position-limiting fit for reciprocating movement along the axial direction. The hydraulic clutch 10 connects with the regulator 5 below through the bearing device 8 . The upper and middle parts of the hydraulic clutch 10 are respectively provided with inner splines and...

Embodiment 2

[0027] On the basis of embodiment 1, refer to the appended Figure 4 , the reciprocating positioning mechanism between the regulator 5 and the central shaft 1 is an inherent positioning pin 6 on the central shaft 1, and a positioning groove is processed on the regulator 5, and the positioning groove is a continuous "N" shape evenly distributed on the inner wall of the regulator. The positioning pin 6 forms a sliding fit with the positioning groove.

[0028] The foregoing embodiment is further refined into:

[0029] The step surface is processed in the positioning groove.

[0030] The oil storage chamber 7 is preset between the regulator 5 and the hydraulic clutch 10; the lower end of the lower spline of the hydraulic clutch 10 is processed into an introduction angle.

[0031] The nozzle 14 is composed of a single nozzle body or a plurality of nozzle bodies; on the sealing surfaces of the central shaft 1 and the outer casing 2, the regulator 5 and the central shaft 1 and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com