Rotary-tooth drilling bit

A drill bit and rotation direction technology, which is applied in construction and other directions, can solve the problems of insufficient drilling capacity of a single drill bit, lower drilling speed of the drill bit, and short service life of the drill bit, so as to improve the drilling capacity, shorten the drilling cycle and save drilling costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Below in conjunction with accompanying drawing, the present invention is described in further detail:

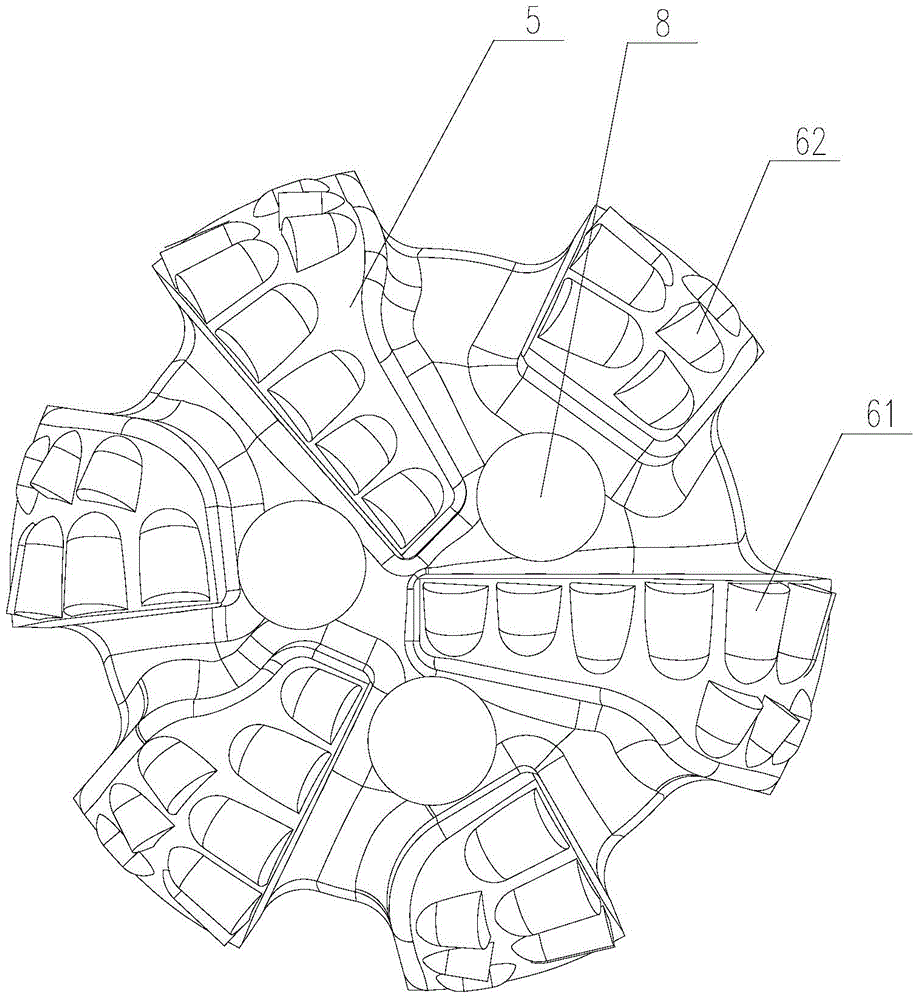

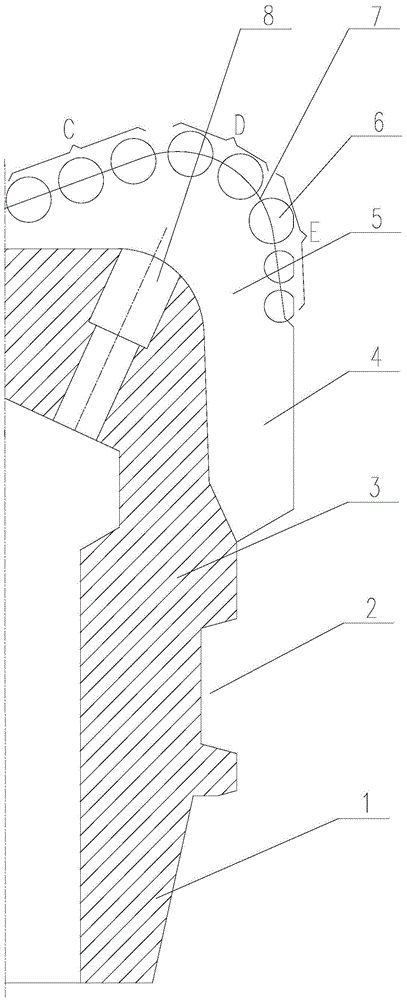

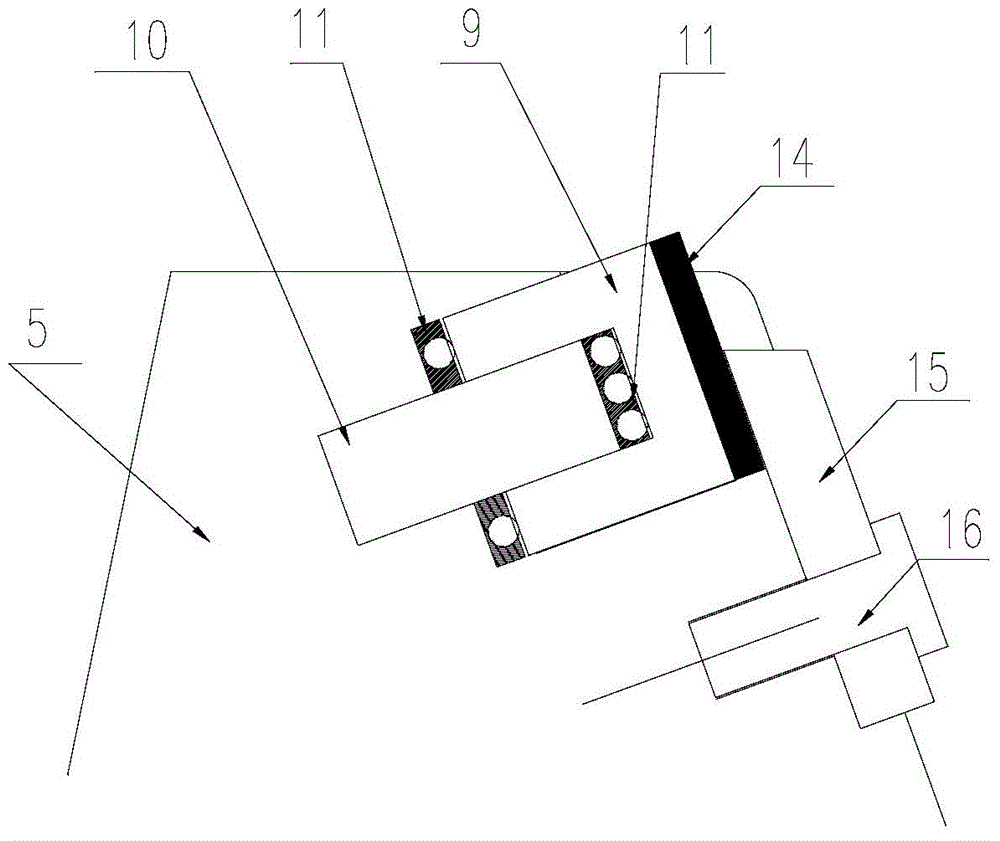

[0033] Such as figure 1 and figure 2 As shown, the rotary tooth drill bit of the present invention includes a joint 1, a base body 3, a blade 5 and a cutting tooth 6, the joint 1 and the base body 3 are integrally formed, the base body 3 is provided with a shackle groove 2, and the cutting teeth 6 are arranged on the blade 5 and is distributed on the tooth line 7, with the advancing direction of the drill bit in use as the front (i.e. figure 2 upper middle), the front end extends to the cutting tooth 6 on the blade 5 close to the center point of the front end surface of the base body 1 as the main cutting tooth 61, and the cutting tooth 6 on the blade blade 5 whose front end is far from the center point of the front end end surface of the base body 1 6 is the rear row of cutting teeth 62, and the substrate 3 between the adjacent blades 5 is provided with a water e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com