Novel spiral drilling rig structure

A screw drilling tool, a new type of technology, is applied in drilling equipment, directional drilling, earthwork drilling and production, etc. It can solve the problems of excessive size of the whole machine, reduce the hydraulic power of the drill bit, and large pressure drop consumption, etc., and achieve low maintenance costs in the later period. The effect of improving drilling efficiency and reducing drilling cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

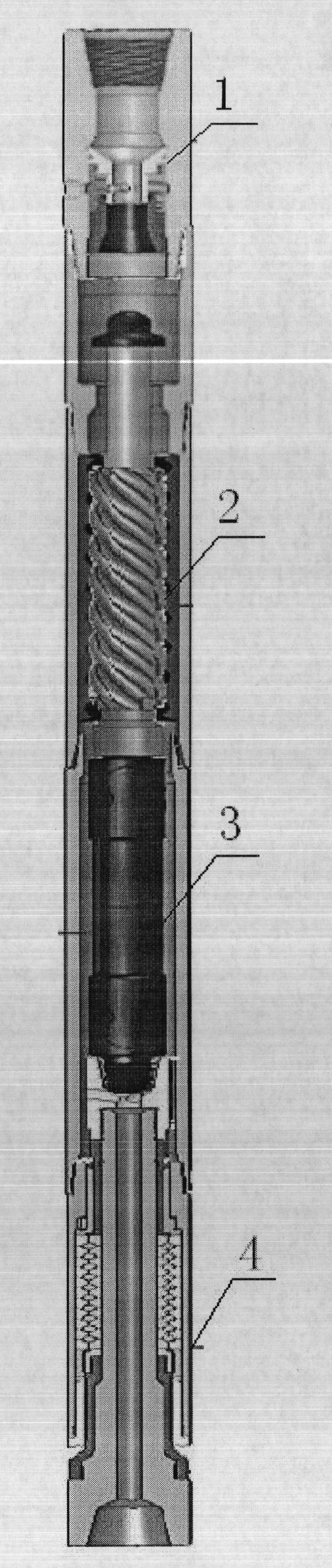

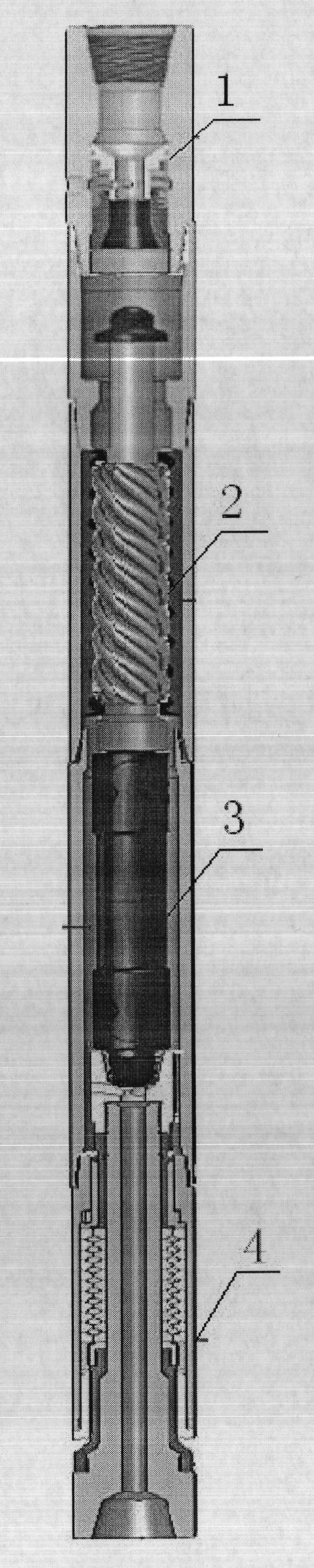

[0021] Such as figure 1 As shown, the present invention is mainly composed of a bypass valve assembly 1, a motor assembly 2, a cardan shaft assembly 3, and a transmission shaft assembly 4 which are connected in sequence.

[0022] The bypass valve assembly 1 is an auxiliary part of the screw drilling tool. Its function is to communicate the inner space of the drill string with the annulus when the pump is stopped, so as to avoid drilling fluid spillage and pollution in the drill string when tripping out and replacing a single screw. Drill floor, affecting normal work. The bypass valve is composed of valve body, valve core, spring, sieve plate and so on. When the pump is turned on, the drilling fluid pressure forces the valve core to move downward, causing the spring to compress and close the channel on the valve body (generally, there are 5 channel holes evenly distributed along the circumference, and a sieve plate is installed to filter foreign matter). Drilling fluid can be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com