Laser drilling device

A drilling and laser technology, applied in drilling equipment, earthwork drilling, drilling equipment and methods, etc., can solve the problems of drilling tool wear, high cost, low drilling speed, etc., and achieve low drilling cost, fast drilling speed and saving Effect of Drilling Cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

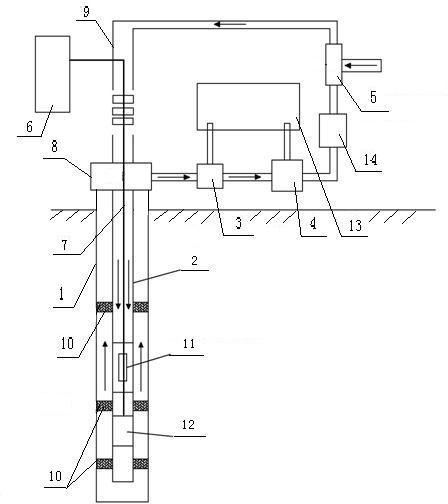

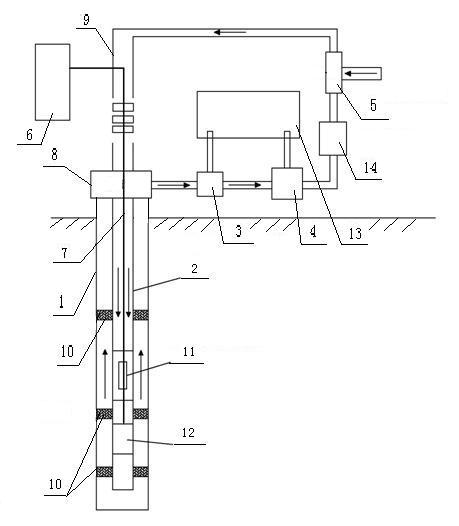

[0020] Below in conjunction with accompanying drawing, the present invention will be further described:

[0021] Such as figure 1 As shown, this laser drilling device includes a surface part and an underground part. The underground part is mainly a drilling device installed in the wellbore, and the surface part is a device for supplying power to the underground drilling device, providing high-pressure gas, and processing bottom lava or dust. . Such as figure 1 As shown, a casing head 8 is installed in the wellhead above the ground to keep the inside of the wellbore 1 closed so as to realize gas circulation. A casing is laid at the surface depth of the wellbore 1, and the casing is a conventional casing with a length of about 100-200m. The conduit 2 extends downward into the wellbore 1 and extends to the bottom of the wellbore 1. The conduit 2 is a coiled pipe or a drill pipe, or it can be a string of other materials with high temperature resistance and certain strength and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com