Method for freezing formation water in gas drilling process

A technology of gas drilling and formation water production, which is applied in the direction of liquid/gas jet drilling, drilling equipment, drill pipe, etc., which can solve the problems of prolonging the construction time of gas drilling and shortening the drilling cycle, so as to shorten the drilling cycle and prolong the construction The effect of the well section

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

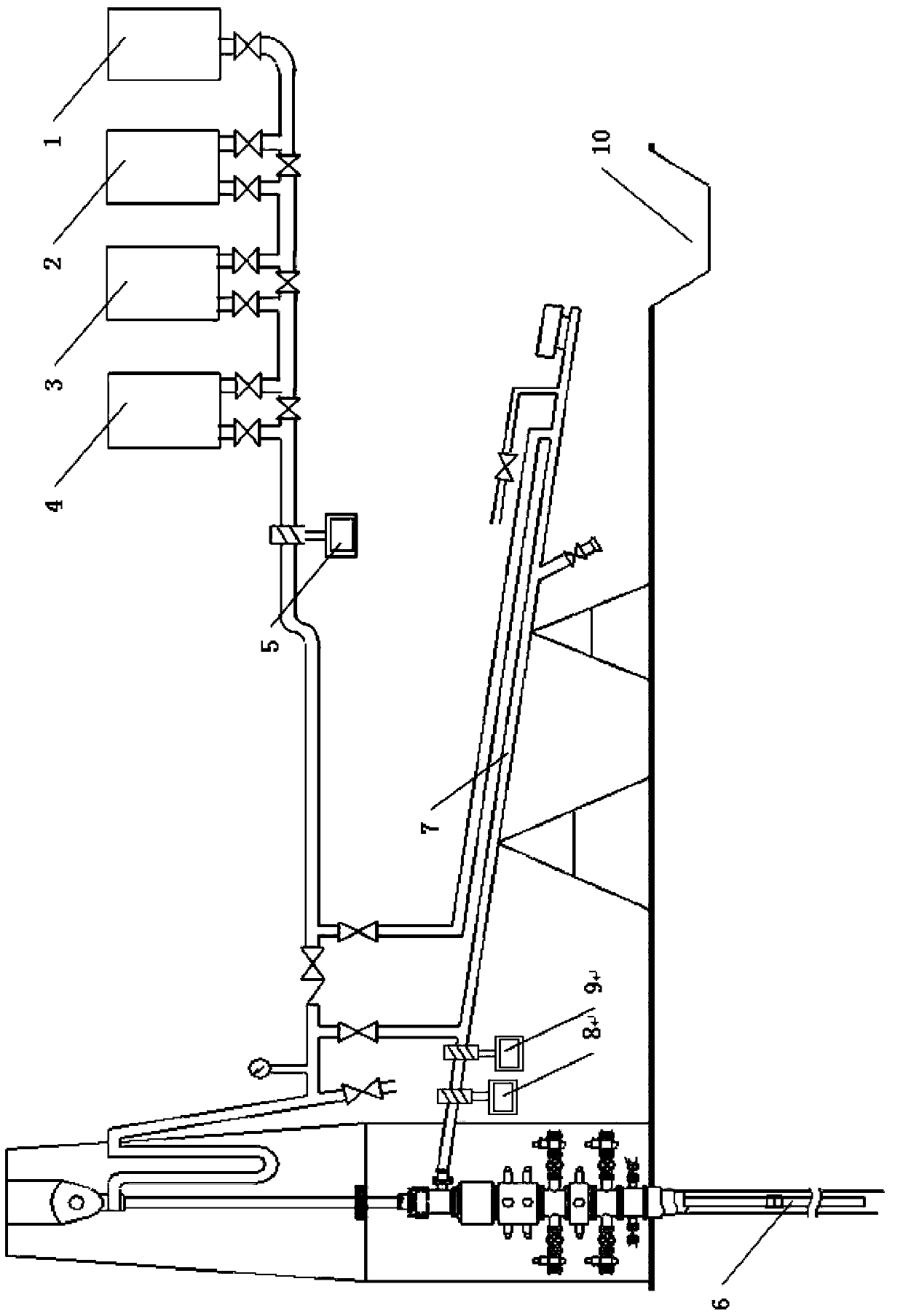

[0018] The present invention will be further described below in conjunction with accompanying drawing:

[0019] The invention provides a method for freezing formation water produced during gas drilling, and the specific implementation process is as follows:

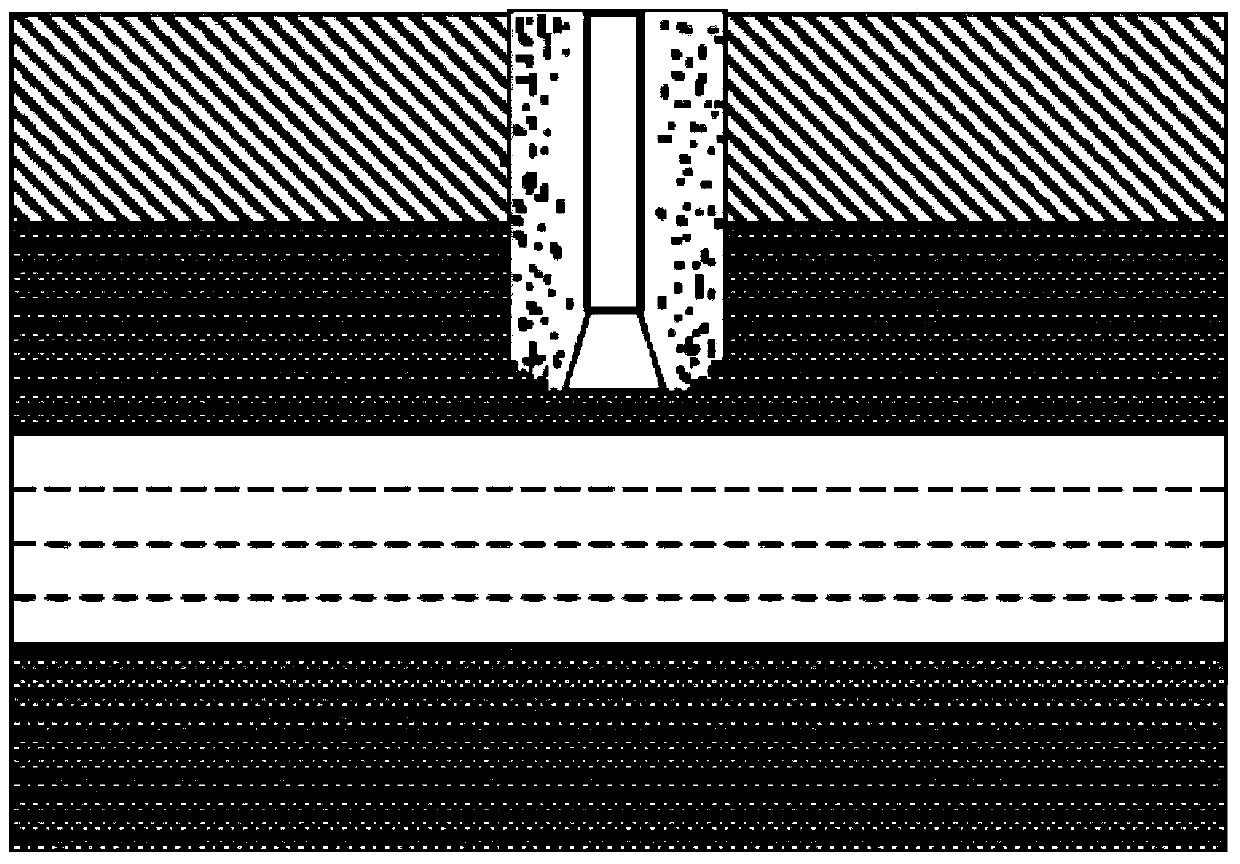

[0020] (1) Conventional gas drilling is carried out before drilling into water-producing formations. At this time, the annulus is mainly gas and cuttings, see figure 2 shown;

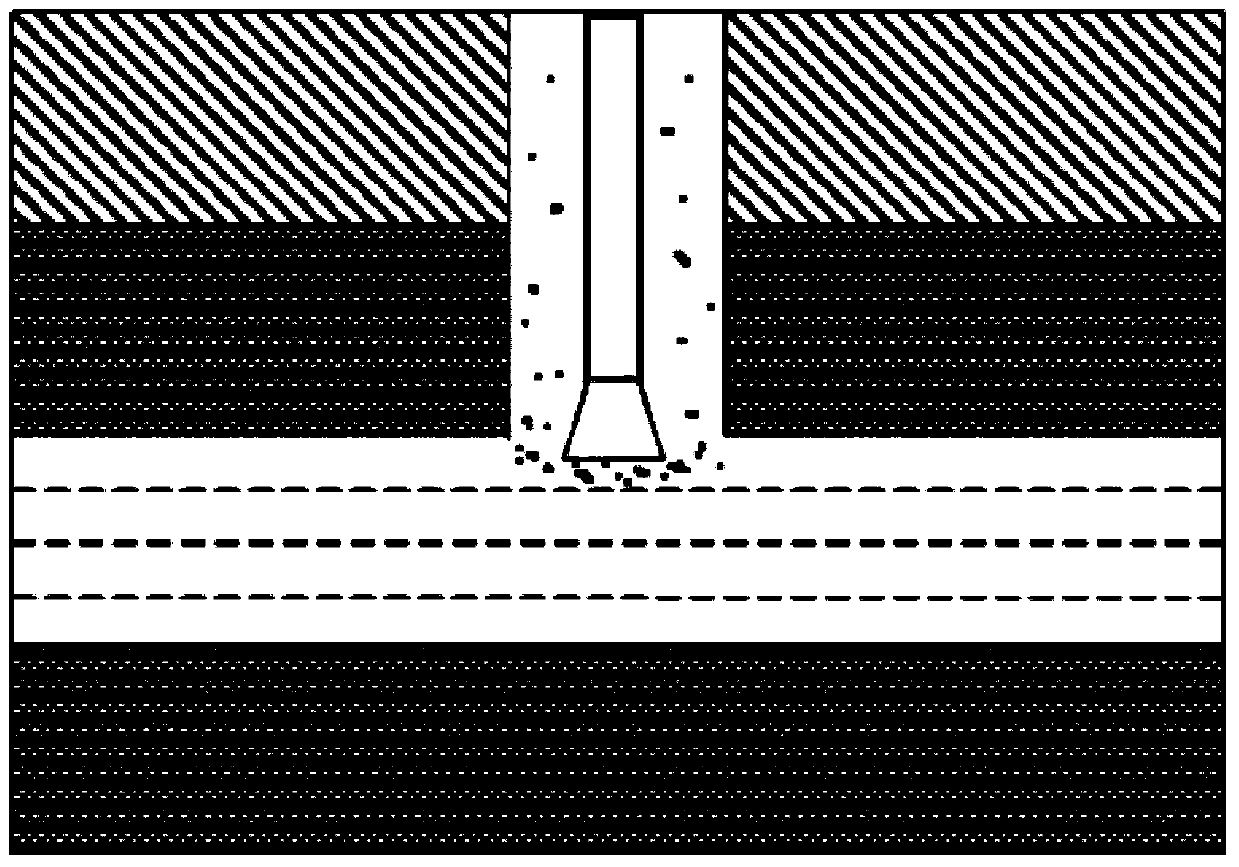

[0021] (2) When the gas drilling encounters the water-producing layer, the initial drilling cuttings return to the bonding phenomenon, and the amount of cuttings is significantly reduced, indicating that the formation is water-producing. See image 3 shown;

[0022] (3) When water is found in the formation, first complete the installation of the well site condenser 4, the gas temperature detection device 5 entering the well, the humidity sensor 8 and the temperature sensor 9, and the replacement of the ultra-low temperature drill pipe in the wel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com