Polycrystalline diamond compact (PDC) bit with rotatable cutting tooth

A cutting tooth and drill bit technology, applied in drill bits, drilling equipment, earth-moving drilling, etc., can solve the problems of reduced drilling efficiency of the drill bit, increase of the temperature of the cutting tooth, and drill bit failure, so as to improve the footage capability and improve the impact resistance capability. , the effect of saving drilling costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described with reference to the accompanying drawings.

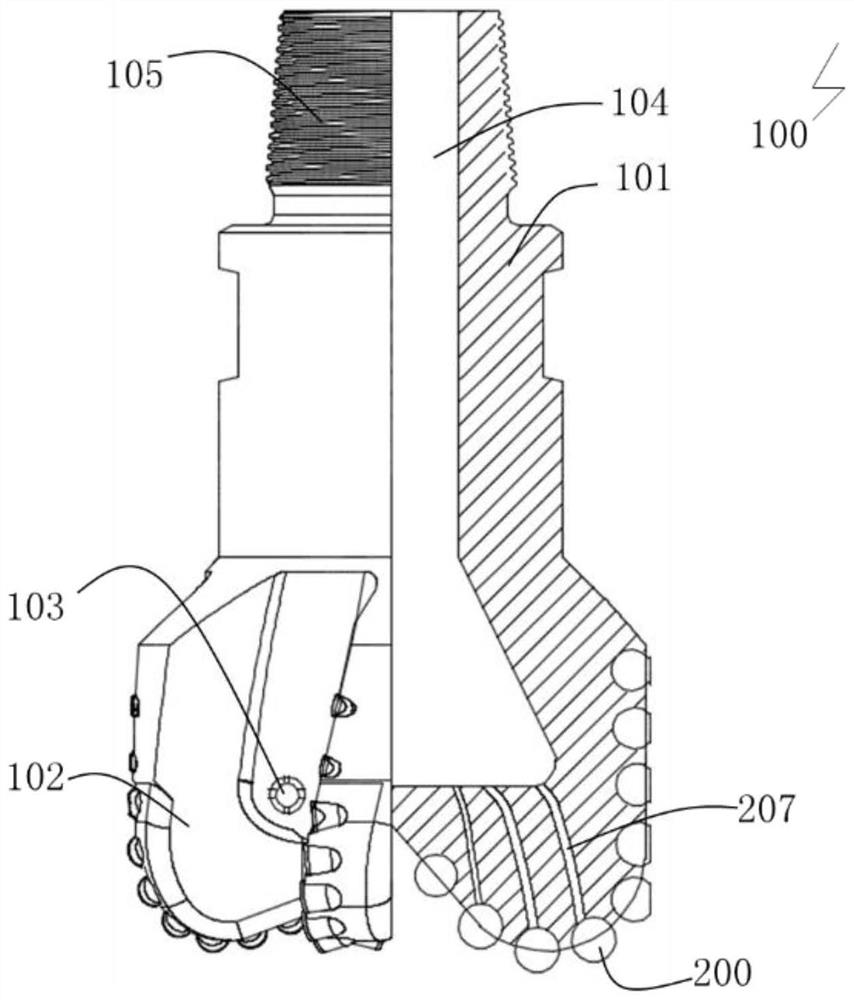

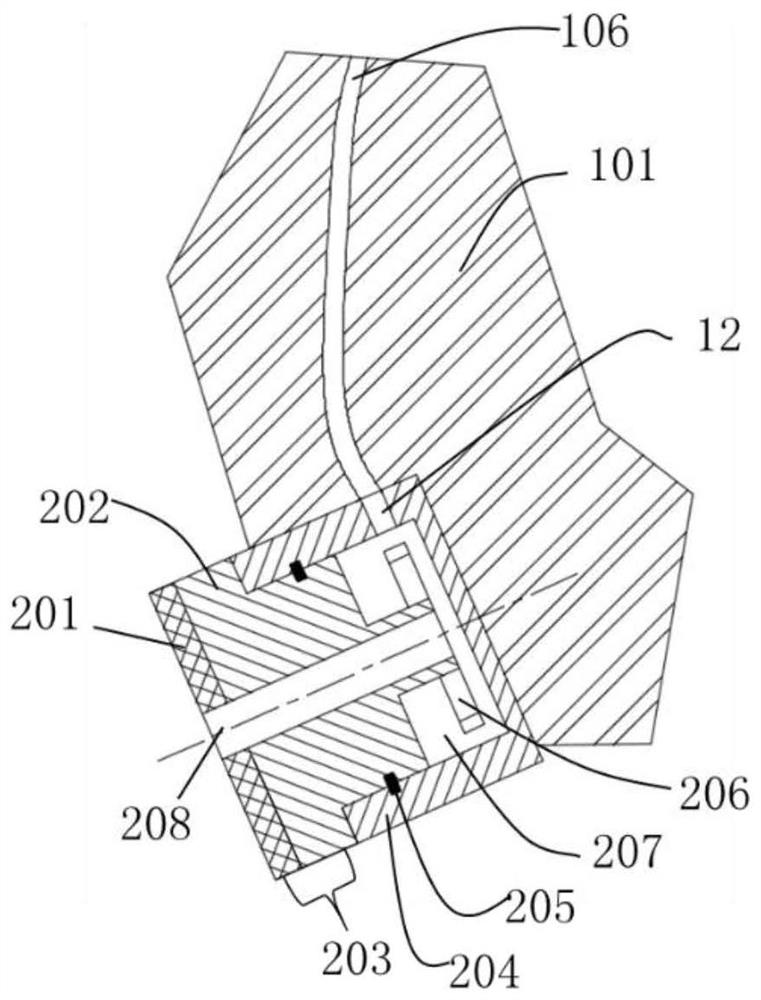

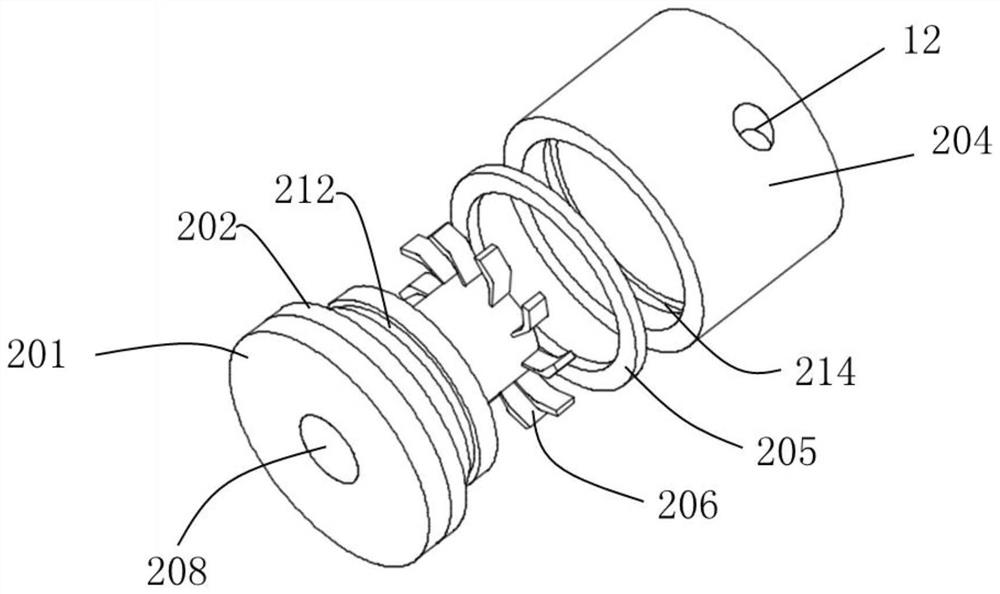

[0030] Such as Figure 1-Figure 4 As shown, the present invention provides a kind of cutting tooth rotatable PDC bit 100, comprises bit body 101, is provided with blade 102, nozzle 103, fluid main channel 104 and taper thread 105 on the bit body 101, taper thread 105 and upper drill The rod is connected, the nozzle 103 communicates with the main fluid channel 104, and the cutting teeth 200 are installed on the blade 102. Generally, the diamond cutting teeth are composed of a wear-resistant layer 201 (generally polycrystalline diamond) and a matrix 202. The cutting tooth provided by the present invention is composed of a central rotating tooth 203, a bushing 204, a limiter 205 and a hydraulically driven rotator 206, wherein the ce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com