Rotary guiding drilling tool

A rotary steerable drilling and tool technology, applied in directional drilling and other directions, can solve the problems of slow directional drilling, supporting pressure, sticking of drilling tools, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

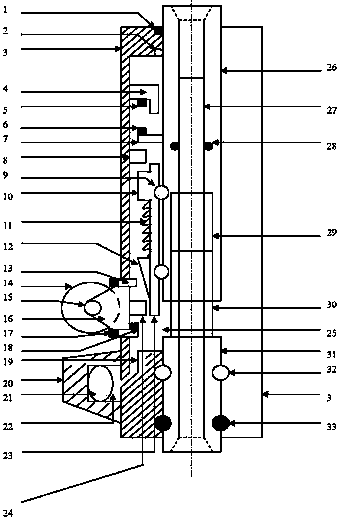

[0010] Depend on figure 1 It can be seen that the present invention is composed of non-rotating overcoat 3, rotating mandrel, guide, and orientation control mechanism. Non-rotating overcoat 3 is a hollow tubular body, and the upper and lower ends are diameter-reducing sections. A guide and a fixed centralizer 20 are installed on the wall from top to bottom; the rotating mandrel is composed of an upper rotating mandrel 26 and a lower rotating mandrel 31, and there is a Sealing ring 1 and ball 2, the lower part of the upper rotating mandrel 26 has an inner card slot 29, and the outer part is set with a ring-shaped pusher 23 through the ball 9, the lower part of the ring-shaped pusher 23 is a tapered pusher 12, and the upper part is a stopper 10. The conical push block 12 is suspended on the lower part of the stopper 10 through the spring 11; the middle part of the lower rotating mandrel 31 is the inserting rod 30 corresponding to the slot 29 in the lower part of the upper rotat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com