Actuating mechanism of formation pressure measurement instrument while drilling

A technology of formation pressure and measuring instruments, which is applied in the directions of measurement, earthwork drilling and production, wellbore/well components, etc., can solve problems such as undisclosed detailed plans, achieve enhanced safety, improve safety and reliability, and reduce sticking The effect of the risk

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the embodiments and the accompanying drawings.

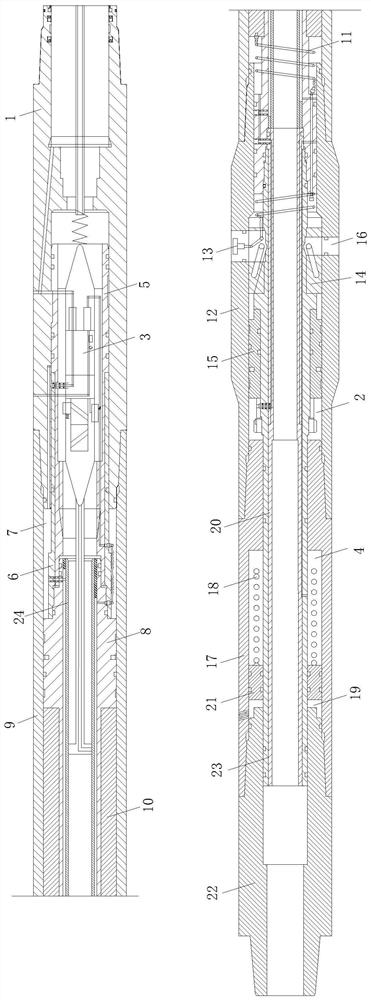

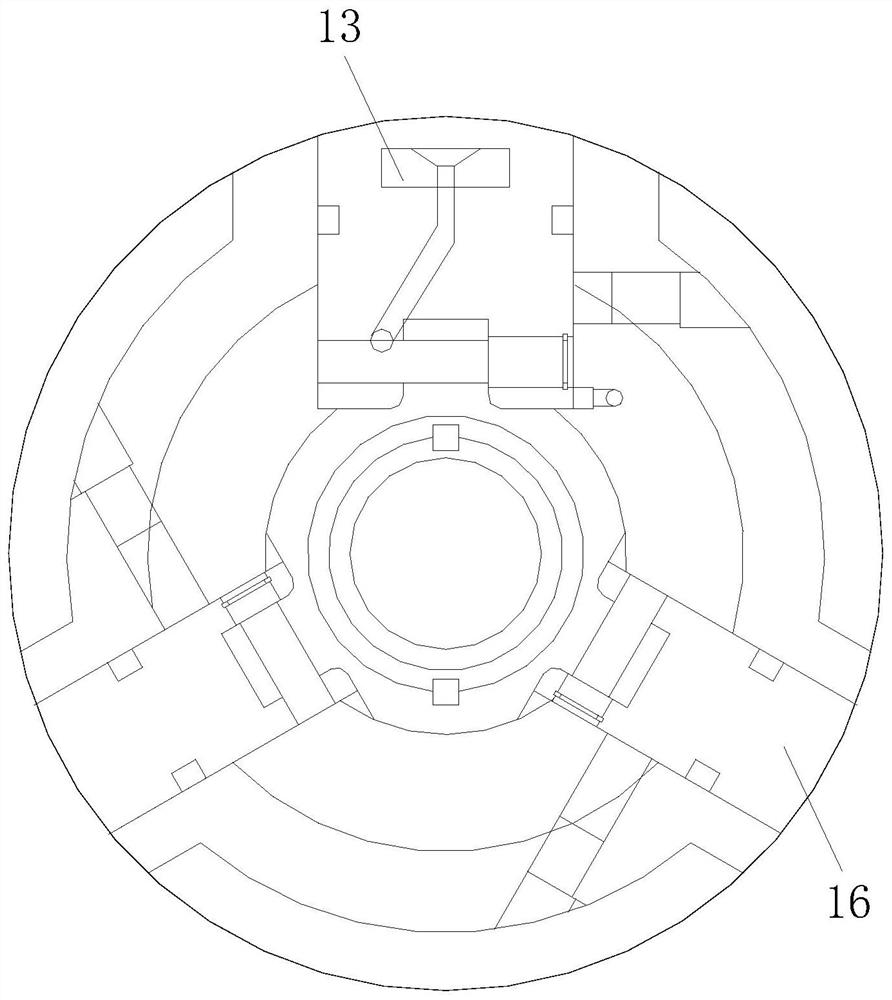

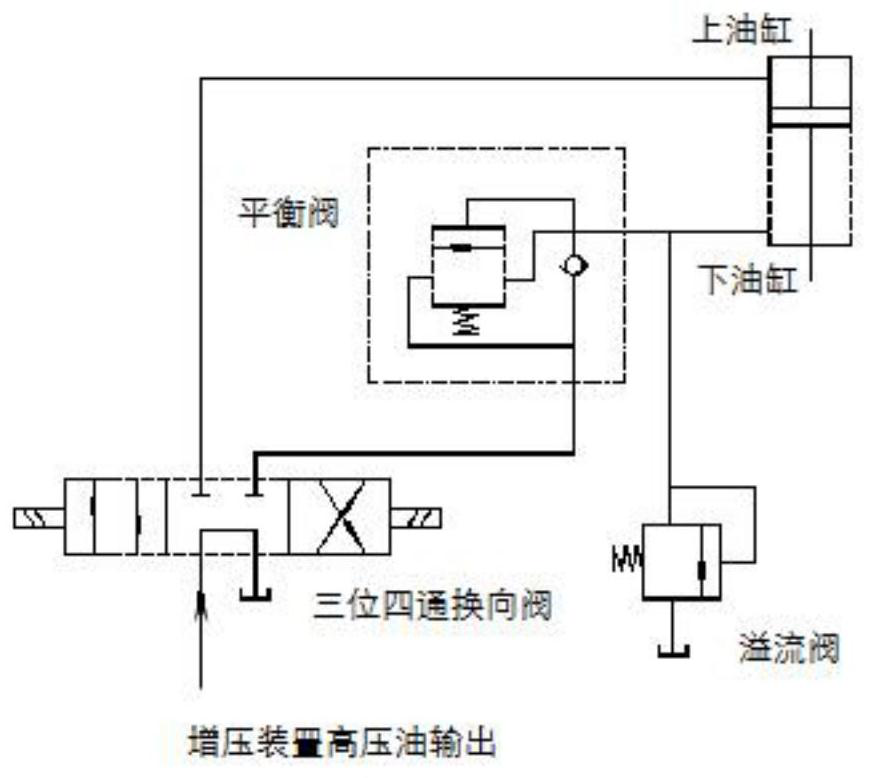

[0026] Such as figure 1 with 2 As shown, the executive mechanism of a formation pressure measuring instrument while drilling of the present invention includes a reversing valve housing 1, a reversing valve 3, a valve core 5, a connecting sleeve 6, an upper piston 8, an upper piston housing 9, a suction System 10, elastic tubing 11, executive body 12, test probe 13, inclined plane thrust block 14, lower end piston 15, three support blocks 16, main shaft 23, central shaft 24, central thrust shaft 20, lower protection joint 22, the lower The protection joint 22, the executive body 12, the upper piston casing 9, and the reversing valve casing 1 are connected in sequence;

[0027] The central thrust shaft 20 is installed in the main shaft, the lower end piston 15 is sleeved on the main shaft, the inclined thrust block 14 is fixed on the main shaft 23, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com