Mud compensation device of supersonic imaging logger

A logging instrument and ultrasonic imaging technology, applied in the direction of instruments, wellbore/well components, geophysical measurement, etc., can solve the problem of not easily detected ultrasonic echoes, etc., to reduce the risk of sticking, reduce attenuation, Reduce the effect of propagation attenuation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

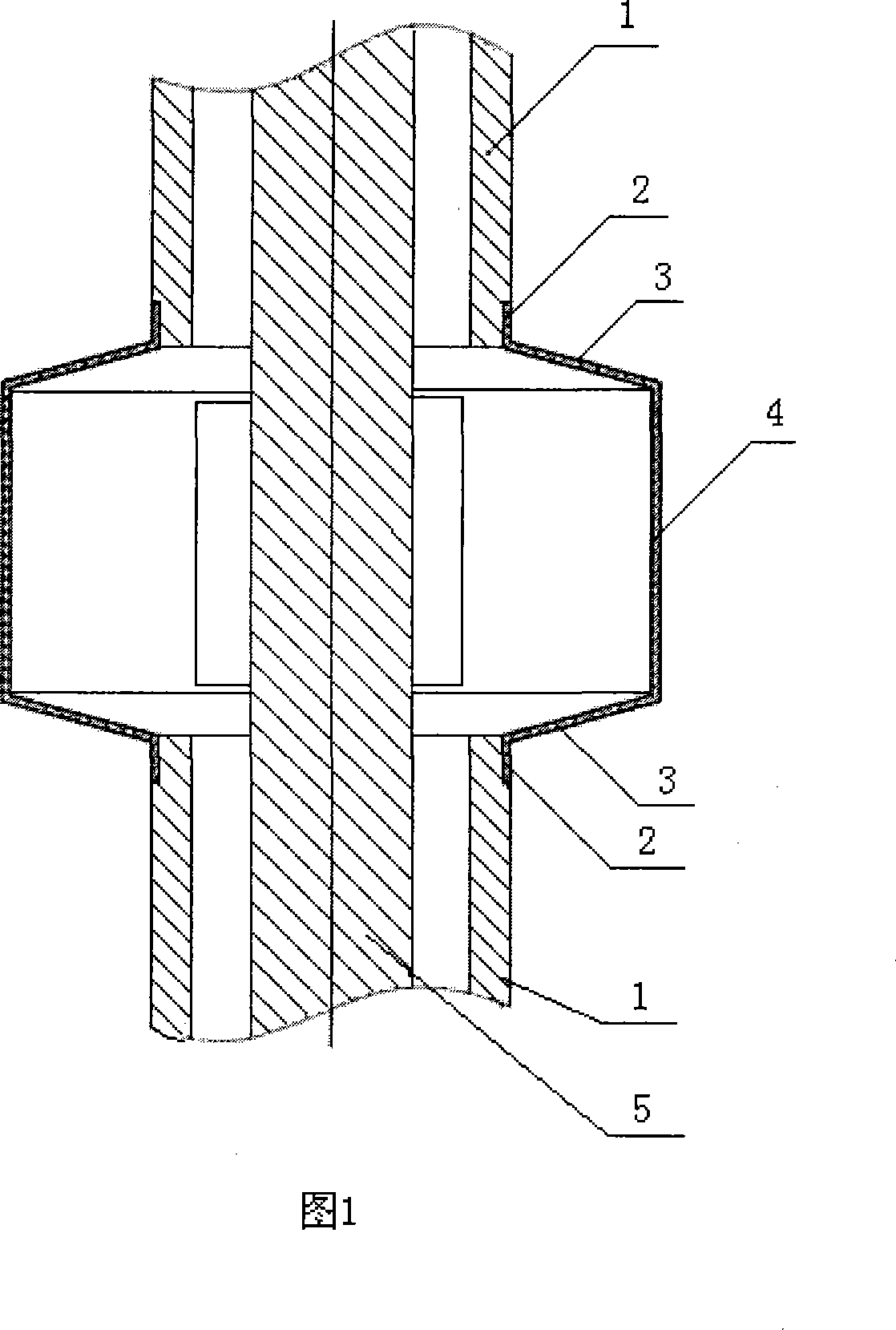

[0013] Example 1. See Figure 1. Taking a mud compensation device in an ultrasonic imaging logging tool suitable for logging in a borehole wall with a diameter of 165.1mm as an example, it will be described. The connecting section 2, the conical transition section 3 and the sound-permeable window 4 are integrally made of polytetrafluoroethylene with a wall thickness of 6 mm. The connecting section 2 at both ends is cylindrical, with an outer diameter of 90mm, and the ends of the connecting section 2 have internal threads. The sound-transmitting window 4 is in the middle of the two connecting sections 2, the sound-transmitting window 4 is a protruding cylinder with an outer diameter of 165.1mm, and the height of the sound-transmitting window 4 is 80mm. There is a cone transition section 3 between the connection section 2 and the sound-transmitting window 4. The inclination angle of the hypotenuse of the cone transition section 3 is 15 degrees. The upper connection section 2 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com