A plowing type PDC drill bit suitable for hard formations

A technology for hard formations and drill bits, which is applied to drill bits, drilling equipment, earthwork drilling and production, etc. It can solve the problems of short life of drill bits and low drilling efficiency, and achieve the effects of reducing rock strength, rapid drilling, and destroying internal stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

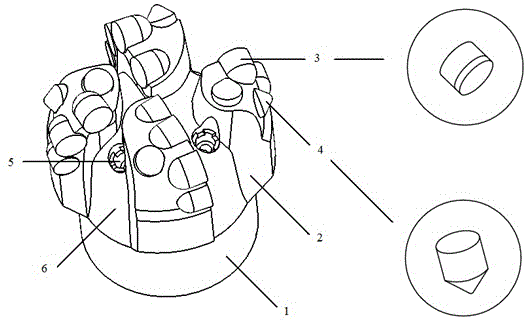

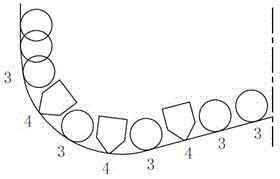

[0026] When the tapered PDC teeth 4 and the polycrystalline diamond composite sheet 3 are alternately arranged, as figure 2 As shown, the bottom hole cutting track of the conical PDC tooth 4 is located between the bottom hole cutting tracks of adjacent polycrystalline diamond compacts 3 on the bottom hole contour line. The polycrystalline diamond composite sheet is used as the main cutting tooth of the blade, and is arranged on the blade in a backward tilt manner, and the backward tilt angle of the composite sheet ranges from 7 degrees to 13 degrees. The conical PDC teeth are used as the rear row of teeth of the blade, and are arranged on the blade in a forward-inclination manner. The forward inclination angle of the conical teeth ranges from 13 degrees to 18 degrees. When the tapered PDC teeth and the polycrystalline diamond composite sheet are arranged in a staggered manner, the cutting edge heights of the two are the same.

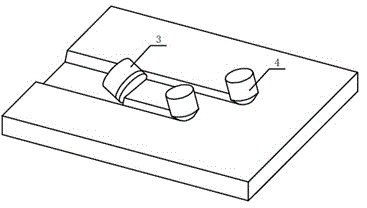

[0027] Such as image 3 As shown, during the d...

Embodiment 2

[0029] When the tapered PDC teeth 4 are arranged in the same track as the polycrystalline diamond composite sheet 3, as Figure 4 As shown, the bottom-hole cutting trajectory of the conical PDC cutter 4 is the same as the bottom-hole cutting trajectory of one of the polycrystalline diamond compacts 3 on the bottom-hole contour line. The polycrystalline diamond composite sheet is used as the main cutting tooth of the blade, and is arranged on the blade in a backward tilt manner, and the backward tilt angle of the composite sheet ranges from 7 degrees to 13 degrees. The conical PDC teeth are used as the rear row of teeth of the blade, and are arranged on the blade in a forward-inclination manner. The forward inclination angle of the conical teeth ranges from 13 degrees to 18 degrees. When the tapered PDC teeth and the polycrystalline diamond composite sheet are arranged on the same track, the cutting edge height of the tapered PDC teeth is 2 mm or less lower than that of the pol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com