Grouting stoppage and guide repair method for leakage of deformation joint and special grouting device for grouting stoppage and guide repair method for leakage of deformation joint

A deformation joint and grouting technology, which is applied in the repair of basic structures, water conservancy projects, artificial islands, etc., can solve the problem that it is difficult to ensure the sealing effect, the inability to mix the glue and water evenly, and the inability to ensure the coordination of the glue and water Ratio and other issues to achieve the effect of eliminating leakage problems and overcoming bad defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

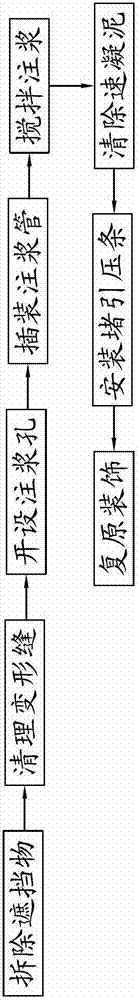

[0026] A method for repairing leakage of deformation joints by grouting and plugging, the construction process flow chart is as follows figure 1 As shown, it includes the following steps:

[0027]The first step is to remove the shield, remove the decorative panel and the rubber water retaining plate, and expose the leaking deformation joint;

[0028] The second step is to clean the deformation joints, clean up the inclusions on the surface of the deformation joints, pick out a groove with a depth of 30-40 mm along the deformation joints, and set up a water diversion channel leading to the drainage system at the lower end of the grooves;

[0029] The third step is to open grouting holes, and set inclined holes at intervals in the groove of the deformation slot. The angle between the inclined holes and the ground is 5 degrees to 15 degrees, and the hole depth exceeds the concrete layer by 100 to 150 mm;

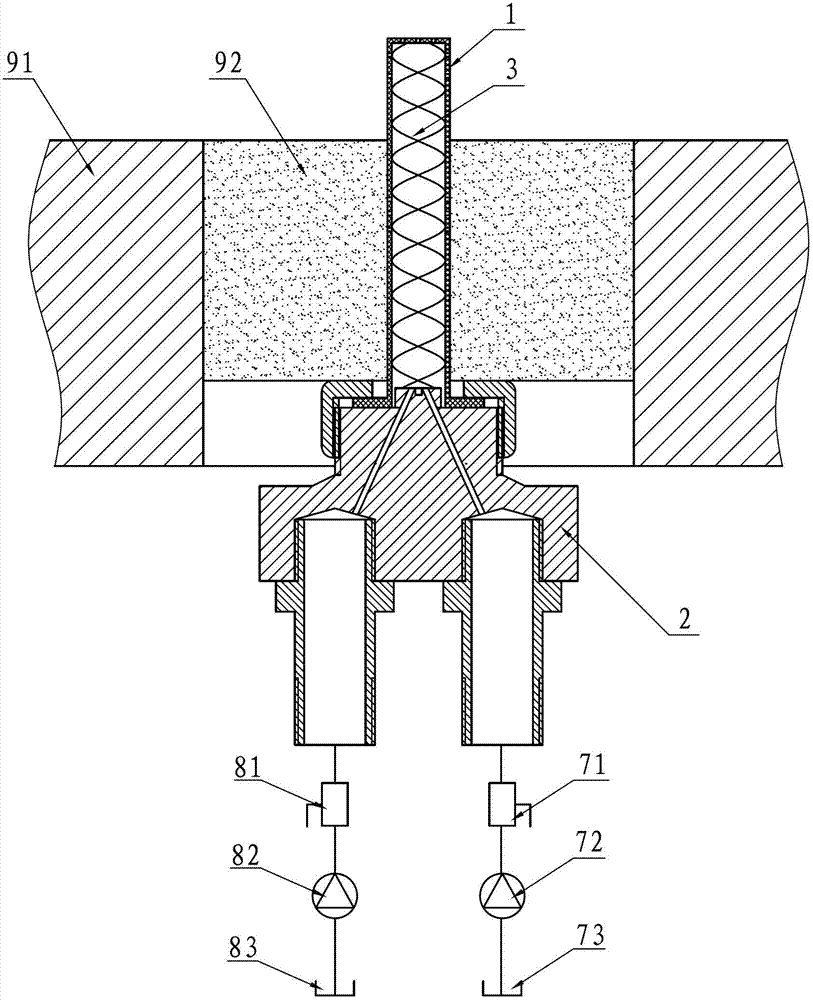

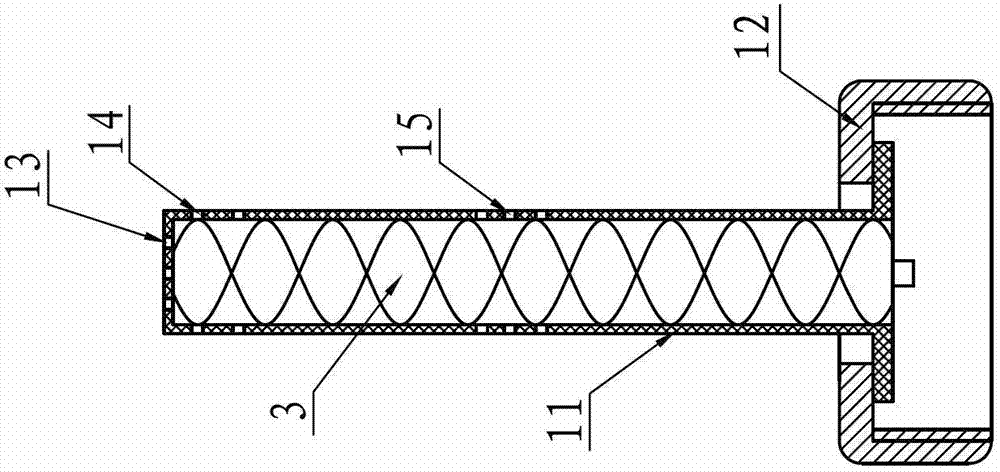

[0030] The fourth step is to insert the grouting pipe, insert the agitati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com